Elon Musk Says Incentives, Logistics Cost Will Influence Site of New U.S. Tesla Factory -- Update

March 10 2020 - 10:49PM

Dow Jones News

By Tim Higgins

Tesla Inc.'s decision on where to build a new U.S. automobile

assembly factory will be influenced by state incentives as well as

access to a large workforce and low logistics costs, Chief

Executive Elon Musk said.

Mr. Musk on Tuesday said on Twitter that the Silicon Valley

electric-car maker is scouting locations for a new factory in the

U.S. to build the company's coming pickup truck and Model Y compact

sport-utility vehicle.

"Incentives play a role, but so do logistics costs, access to a

large workforce with a wide range of talents, and quality of life,"

he later told The Wall Street Journal in an email.

President Trump in January had suggested Tesla was planning to

erect a new factory in the U.S. Mr. Trump, in an interview with

CNBC, said he had talked with Mr. Musk and that the auto maker

planned to build a "very big plant" in the U.S.

Mr. Musk, via Twitter on Tuesday, said the facility would be

placed in the central part of the U.S., a region of the country

that fuels many pickup sales for competitors Ford Motor Co. and

General Motors Co. He also said, in a second social-media post,

that production for the Model Y would serve East Coast

customers.

Excitement over Tesla's growth ambitions and success in opening

an assembly factory in China in recent months has helped fuel a

sharp rise in company shares. Even after a recent selloff in stock

over broader concerns about the spreading novel coronavirus, Tesla

shares closed Tuesday 54% higher this year.

Tesla is targeting at least a 36% increase in deliveries this

year, in part from the additional production capacity coming from

its new China factory. The arrival of the Model Y, which the

company has said should begin delivering by month's end, has the

potential to further stoke the company's deliveries. Consumers in

the U.S., and China have been gravitating toward smaller SUVs and

away from sedans.

The arrival of the Model 3 compact car in 2017, the company's

highest production vehicle, and Model Y this year are part of a

broader strategy by Mr. Musk to pivot Tesla from being a niche

luxury brand into a car company that sells millions of electric

vehicles around the world.

Tesla also has begun site work to build a factory outside of

Berlin to add to its assembly capacity in China and California. It

plans an initial output, starting in 2021, of 150,000 cars in

Germany, growing to 500,000 at a later date.

The new U.S. factory announced Tuesday would be Tesla's fourth

assembly facility. The company also has a large battery factory in

Nevada.

Investor sentiment around Tesla improved significantly in the

fall. The company reported a surprise third-quarter profit. Then,

at an event in November, Mr. Musk revealed a pickup dubbed the

Cybertruck, with a stark design that drew significant social media

attention. He has said that 250,000 people have put down money to

preorder the vehicle. Tesla has suggested production of the truck

would begin around late 2021.

The company took advantage of the enthusiasm around its

prospects to raise more than $2 billion in February by issuing new

shares. The money helps bolster the company's access to cash. It

was raised before the spread of the novel coronavirus in the U.S.

spurred uncertainty over economic growth.

The company has warned that efforts to contain the coronavirus

in China could hinder its first quarter. Other auto makers have

seen dramatic declines in sales as the country essentially came to

a grinding halt. Tesla will release first-quarter delivery results

in early April.

Write to Tim Higgins at Tim.Higgins@WSJ.com

(END) Dow Jones Newswires

March 10, 2020 22:34 ET (02:34 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

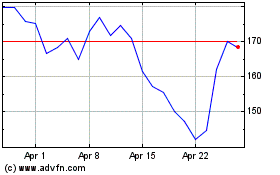

Tesla (NASDAQ:TSLA)

Historical Stock Chart

From Aug 2024 to Sep 2024

Tesla (NASDAQ:TSLA)

Historical Stock Chart

From Sep 2023 to Sep 2024