GE Unit Expands Program to Speed U.S. Imports Through Supply Chains

March 06 2018 - 1:01PM

Dow Jones News

LONG BEACH, Calif.--Companies that ship and handle goods moving

through supply chains have a problem: they don't often know where

their shipments are in far-flung freight networks or when they will

arrive.

GE Transportation, a division of General Electric Co., said this

week it will work with California's Port of Long Beach, the

nation's second largest container port, to collect information on

inbound cargo and share it with transport and logistics operators

that now have only a murky view of when shipments will land at

docks and distribution centers.

At least two Long Beach terminals will participate in a two- to

three-month pilot of a program aimed at speeding up the flow of

goods from import gateways to warehouses, stores and factories by

giving companies a better idea of when and where to place the

trucks, railcars and other equipment that carry shipments through

distribution channels.

The program follows a similar test-run at the neighboring Port

of Los Angeles, the nation's top container port, which launched in

late 2016. Los Angeles expanded that pilot last summer and said it

expects an 8% to 12% improvement in overall supply chain efficiency

once the program rolls out across the entire port.

GE Transportation's Port Optimizer software brings together data

from shipping companies, port terminal operators, freight railroads

and other supply chain players into a single portal, and makes the

information available two weeks before a cargo ship arrives. GE

Transportation also said it's now working with software provider

project44 to make all the data available in real time.

"Until everyone is getting that information, you're going to run

into a friction point," said Jennifer Schopfer, vice president of

transport logistics at GE Transportation.

Without the software, many of the firms involved may not know

what's coming until as little as two days before it arrives; even

when shipping information is provided to the cargo owner, it

doesn't always reach the freight haulers that pull containers from

the port.

With all the information in one place, Ms. Schopfer said,

carriers and service providers will have time to line up the right

equipment and labor, make appointments for container pickup and

drop-off, plan where containers will be stowed on the docks and

make other arrangements. "Those people all have to work together to

move the cargo and they can't work together if they're not sharing

the information," she said.

"Tools like this will help us track our inventory more closely,"

said Deborah Ryan, vice president of global transportation and

logistics at Ascena Retail Group Inc., which owns Ann Taylor, Lane

Bryant and other women's apparel brands.

"The ability to know exactly where cargo is at any given time

will help us make better decisions about how to deploy inventory,"

Ms. Ryan said. "The ability to analyze historical performance will

enable us to choose the most reliable providers as well as pinpoint

where bottlenecks may occur and take proactive measures."

Last year, the ports of Los Angeles and Long Beach handled a

combined 16.9 million 20-foot equivalent units, a standard measure

for container cargo.

Write to Erica E. Phillips at erica.phillips@wsj.com

(END) Dow Jones Newswires

March 06, 2018 12:46 ET (17:46 GMT)

Copyright (c) 2018 Dow Jones & Company, Inc.

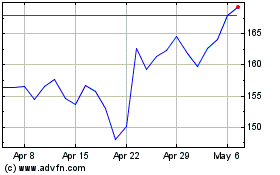

GE Aerospace (NYSE:GE)

Historical Stock Chart

From Mar 2024 to Apr 2024

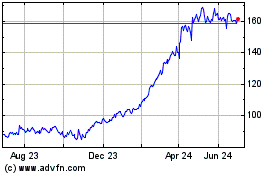

GE Aerospace (NYSE:GE)

Historical Stock Chart

From Apr 2023 to Apr 2024