UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM SD

Specialized Disclosure Report

TETRA Technologies, Inc.

(Exact name of registrant as specified in its charter)

|

| | |

Delaware | 1-13455 | 74-2148293 |

(State or other jurisdiction | (Commission File Number) | (IRS Employer |

of incorporation) | | Identification No.) |

| | |

24955 Interstate 45 North |

The Woodlands, Texas 77380 |

(Address of Principal Executive Offices and Zip Code) |

| | |

Bass C. Wallace, Jr. | | (281) 367-1983 |

(Name and telephone number, including area code, of the person to contact in connection with this report.) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

[ X ] Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014.

FORM SD of TETRA TECHNOLOGIES, INC.

Reporting Year ended December 31, 2014

Section 1 - Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

This Specialized Disclosure Report of TETRA Technologies, Inc. (the “Company”) is filed pursuant to Rule 13p-1 promulgated under the Securities Exchange Act of 1934, as amended, for the reporting year ended December 31, 2014.

Conflict Minerals Disclosure

The Company has filed a Conflict Minerals Report as Exhibit 1.01 to this Specialized Disclosure Report. The Conflict Minerals Report is provided on the Company’s publicly available website at http://www.tetratec.com/ under “Investor Relations” and then “Corporate Governance.” The website and the information accessible through it are not incorporated into this Specialized Disclosure Report.

Item 1.02 Exhibit

As specified in Section 2, Item 2.01 of this Form SD, the Company is hereby filing a Conflict Minerals Report as Exhibit 1.01 to this Specialized Disclosure Report.

Section 2 - Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this Report

|

| | |

Exhibit Number | | Description |

1.01 | | Conflict Minerals Report of TETRA Technologies, Inc. |

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

|

| | | |

TETRA Technologies, Inc. (Registrant) | | |

By: | /s/Joseph Elkhoury | | May 28, 2015 |

| Joseph Elkhoury | | (Date) |

| (Senior Vice President & Chief Operating Officer) | | |

| | | |

TETRA Technologies, Inc.

Conflict Minerals Report

For the reporting period from January 1, 2014 to December 31, 2014

This Conflict Minerals Report (this “Report”) of TETRA Technologies, Inc. (referred to herein, together with its consolidated subsidiaries, as the “Company,” “we,” or “our”) has been prepared pursuant to Rule 13p-1 and in accordance with the requirements of Form SD (the “Rule”), each of which was promulgated under the Securities Exchange Act of 1934, as amended (the “Exchange Act”), for the reporting period of January 1, 2014 to December 31, 2014 (the “Reporting Year”).

The Rule requires the Company, as a company required to file reports with the Securities and Exchange Commission (the “SEC”) pursuant to Section 13(a) of the Exchange Act, to take certain actions and to disclose certain information when it manufactures or contracts to manufacture products that contain specified minerals that are necessary to the functionality or production of those products. The specified minerals, which we collectively refer to in this Report as the “Conflict Minerals,” are gold, columbite-tantalite (coltan), cassiterite, and wolframite, including their derivatives, which are limited to tantalum, tin, and tungsten.

As described in this Report, certain of the Company’s operations manufacture products that contain Conflict Minerals that are necessary to the functionality or production of those products. In accordance with the Rule, the Company undertook due diligence to determine the source and chain of custody of Conflict Minerals necessary to the functionality or production of its products. The objective of this due diligence was to determine whether or not these Conflict Minerals originated from the Democratic Republic of Congo, the Republic of Congo, the Central African Republic, South Sudan, Uganda, Rwanda, Burundi, Tanzania, Zambia, or Angola (the “Covered Countries”), and if so, whether sourcing practices directly or indirectly financed or benefited armed groups in the Covered Countries.

Pursuant to guidance provided by the Division of Corporation Finance of the SEC regarding the application of the Rule, this Report has not been subject to an independent private sector audit.

Description of the Company’s Products Covered by this Report

This Report relates to compressors used to provide both conventional wellhead and unconventional compression services that were manufactured by the Company’s consolidated subsidiary, CSI Compressco LP (“CSI Compressco”) during the Reporting Year for sale to third parties (the “Compressors”). A limited number of components that comprise each of the Compressor units contain the Conflict Minerals gold, tantalum, tin, and/or tungsten that are necessary for the functionality or production of the Compressors. The Company determined that it did not manufacture or contract to have manufactured for it during the Reporting Year any product that contained any Conflict Mineral that was necessary to the functionality or production of such product other than the Compressors.

On August 4, 2014, CSI Compressco completed the purchase of all the outstanding shares of Compressor Systems, Inc. Prior to the acquisition, Compressor Systems, Inc. had not been obligated to provide a specialized disclosure report with respect to any Conflict Minerals necessary to the functionality or production of products that it manufactured or contracted to manufacture. As applicable, products manufactured or contracted to be manufactured by this newly acquired company will be included in our Conflict Minerals Report for calendar year 2016.

The Company’s Due Diligence Process

The Company determined that, under the Rule, it was required to exercise due diligence on the source and chain of custody of the Conflict Minerals contained in the Compressors, and exercised such due diligence. The Company’s due diligence measures were designed to conform in all material respects to the framework in the Organisation for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High Risk Areas: Second Edition, including the related supplements on gold, tin, tantalum, and tungsten (collectively, the “OECD Guidance”).

The following is a description of the measures that we took to exercise due diligence on the source and chain of custody of necessary Conflict Minerals contained in the Compressors.

Step 1: Company Management System

Conflict Minerals Policy

We have adopted a policy relating to Conflict Minerals in our products (the “Conflict Minerals Policy”), incorporating relevant standards contained in the OECD Guidance. The Conflict Minerals Policy, which is available at http://www.tetratec.com/ under “Investor Relations” and then “Corporate Governance,” states that we are committed to responsible sourcing of materials for our products, including the sourcing of Conflict Minerals, and to sourcing products from suppliers that share our values regarding ethics, integrity, and respect for human rights. It reflects our expectation that our suppliers will (i) provide appropriate information and conduct necessary due diligence in order to facilitate our compliance with the Rule, (ii) adopt and enforce responsible sourcing practices and policies consistent with the Conflict Minerals Policy, and (iii) require their direct and indirect suppliers to do the same.

Internal Management Team

We have assembled a core team of employees that are involved in various phases of compliance with the Rule, including personnel from Legal, Global Supply Chain and Procurement, Engineering, Manufacturing, and Finance. This core team, which formally reports to senior management, has developed and implemented a Conflict Minerals supplier engagement and due diligence plan.

Senior Management and the Audit Committees of both TETRA’s and CSI Compressco’s Board of Directors were briefed about the results of our supplier engagement and due diligence efforts on a periodic basis in 2014 and 2015.

Control Systems

We have developed a process to retain relevant documentation related to our Conflict Minerals compliance efforts and determinations, including the following

| |

• | documentation used to determine which of the Company’s products were potentially subject to the Rule, |

| |

• | lists of components and parts used by the Company in its manufacturing of the Compressors (the “Components and Parts”) and their associated suppliers, |

| |

• | compilations of At-Risk Suppliers (as defined below), and |

| |

• | communications to and from At-Risk Suppliers about the presence of Conflict Minerals in the Components and Parts purchased by the Company for use in its manufacturing of the Compressors. |

We do not have direct relationships or communications with any Conflict Mineral smelters and refiners (“SORs”). As a result, we have implemented a supplier engagement process, which involves a written Conflict Minerals Disclosure Questionnaire (“Questionnaire”). The Questionnaire is sent to the Company’s At-Risk Suppliers and gathers necessary information and certifications about (i) the presence of Conflict Minerals in the specific Components and Parts purchased by the Company for use in its manufacturing of the Compressors, (ii) the countries of origin and SORs of the Conflict Minerals contained in Components and Parts containing Conflict Minerals supplied to the Company for use in its manufacturing of the Compressors, and (iii) whether such Conflict Minerals directly or indirectly financed or benefited armed groups in the Covered Countries.

Rather than completing the Questionnaire, as requested, some of our At-Risk Suppliers chose provide information related to Conflict Minerals using the due diligence tools developed by the Conflict-Free Sourcing Initiative (‘CFSI”), including the CFSI’s Conflict Minerals Reporting Template (“CFSI Reporting Template”), which is designed to identify the SORs that process the Conflict Minerals in the company’s entire supply chain.

We also maintain a company-level grievance mechanism, as described in our Code of Business Conduct, which enables employees to anonymously report concerns, including, but not limited to, any concerns about our Conflict Mineral supply chain. We communicated this mechanism to our employees through mandatory training sessions, posters, and brochures.

Step 2: Identification and Assessment of Supply Chain Risks

In order to identify and assess the risks in our supply chain, we first conducted a high-level assessment to determine which products the Company manufactured or contracted to manufacture in 2014 contain or may contain Conflict Minerals necessary to the functionality or production of those products. This assessment included a review of typical

industry uses of Conflict Minerals. Next, we identified the suppliers of the Components and Parts that contain (or may contain) necessary Conflict Minerals (hereinafter, “At-Risk Suppliers”).

The Company does not purchase Conflict Minerals directly from mines or SORs. As a downstream company, the Company’s supply chain with respect to the Compressors is complex. We are several tiers removed from mining operations and SORs. The Company must, therefore, rely on our suppliers to assist the Company with our due diligence efforts by providing information regarding the Conflict Minerals’ source and chain of custody or to give the Company access to third parties in the suppliers’ own supply chains and for those third parties to provide information to the Company regarding the source and chain of custody of pertinent Conflict Minerals. Moreover, the Company believes that the SORs of Conflict Minerals are best situated to identify the sources of Conflict Minerals, and therefore has taken steps to identify the applicable SORs of Conflict Minerals in the Company’s supply chain.

We directly engaged with At-Risk Suppliers via email notifying them that we would be updating our Conflict Minerals due diligence and requesting that the At-Risk Suppliers complete the written Questionnaire with regard to the specific Components and Parts purchased by the Company from the At-Risk Suppliers.

We conducted necessary follow-up communications with At-Risk Suppliers when information provided by the suppliers appeared to be incomplete or incorrect or when suppliers failed to respond within a reasonable period of time. When requested by an At-Risk Supplier, we also provided a list of Components and Parts purchased by the Company from the particular At-Risk Supplier.

We reviewed and evaluated the At-Risk Suppliers’ responses for completeness and accuracy and engaged with suppliers regarding their particular responses, if required. We also compared the SORs identified by the At-Risk Suppliers against (i) CFSI’s list of SORs that have been found to be compliant with the relevant Conflict-Free Smelter Program (“CFSP”) assessment protocols and (ii) CFSI’s list of SORs that have committed to undergo a CFSP audit.

Step 3: Strategy to Respond to Identified Risks

As described in our Conflict Minerals Policy, in the event that we have reason to believe that a supplier is supplying us with Conflict Minerals from sources that may directly or indirectly finance or benefit armed groups in the Covered Countries, we may reevaluate the supplier relationship and take any appropriate action, including termination of our relationship with the supplier. If an At-Risk Supplier has been unresponsive or otherwise uncooperative in our Conflict Minerals due diligence efforts and/or is not aligned with our Conflict Minerals Policy, we may also consider reevaluating that supplier relationship.

Step 4: Independent Third-Party Audit of SOR Due Diligence Practices

As stated above, the Company does not purchase Conflict Minerals directly from SORs and there are often a number of third parties in the supply chain between the Company’s direct third-party suppliers of Components and Parts and the original sources of any Conflict Minerals contained in such Components and Parts. Consequently, we do not have direct relationships with SORs and do not perform direct audits of entities within our supply chain. We rely on our suppliers to provide the information regarding any Conflict Mineral contained in the Components and Parts those suppliers sell to the Company.

We support our suppliers’ use of validation, certification, and audit programs of SORs upstream in our supply chain, such as the CFSI, which is sponsored by the Electronics Industry Citizenship Coalition (“EICC”) and Global e-Sustainability Initiative (“GeSI”).

Step 5: Report on Supply Chain Due Diligence

As indicated in the Specialized Disclosure Report on Form SD, this Report and the Company’s Conflict Minerals Policy are publicly available on the Company’s website at http://www.tetratec.com/ under “Investor Relations” and then “Corporate Governance.”

Results of Supply Chain Due Diligence

Our efforts to determine the mine or location of origin of necessary Conflict Minerals in the Compressors with the greatest possible specificity consisted of the due diligence measures described in this Report, including our efforts to seek information from At-Risk Suppliers using the Questionnaire.

We sent Questionnaires to twenty-two (22) suppliers that we identified as At-Risk Suppliers. Nineteen (19) of these twenty-two (22) At-Risk Suppliers responded by providing information using either the Company’s Questionnaire, as requested by the Company, or the CFSI Reporting Template.

The remaining three (3) At-Risk Suppliers, which were each distributors of products manufactured by other companies, responded by providing only a brief letter or written statement. Each of these three (3) At-Risk Suppliers stated in their responses that (i) as distributors, and not manufacturers, they are not subject to the requirements of the Rule, but (ii) if the Company provided a list of the specific Components and Parts purchased by the Company from the supplier and integrated into a manufactured product, the supplier may be able to assist the Company by making reasonable efforts to obtain additional due diligence information about these Components and Parts. We provided such lists to these suppliers and, when we did not receive a response within a reasonable period of time, we followed up with regular communications reiterating our requests for information. As of that date of this Report, however, we have received the requested information regarding only one of the specific Components and Parts purchased by the Company from these three (3) suppliers.

The majority of the twenty-two (22) At-Risk Suppliers that we surveyed indicated that they had not finished the due diligence on their supply chains and, therefore, could not complete the Questionnaire or CFSI Reporting Template. Furthermore, the At-Risk Supplier respondents that provided information using the CFSI Reporting Template rather than the Company’s Questionnaire, as requested, provided company-level information as to all of the SORs in the supplier’s entire supply chain without identifying the SORs used for the particular Components and Parts supplied to the Company. As a result, we do not have sufficient information regarding all of the SORs that processed necessary Conflict Minerals in the Compressors to conclusively determine whether those Conflict Minerals originated in the Covered Countries or whether those Conflict Minerals came from recycled or scrap sources.

After exercising the due diligence described in this Report, however, we have determined that a portion of the necessary Conflict Minerals in the Compressors was sourced from SORs that had been listed by CFSI as being compliant with the relevant CFSP assessment protocol.

Two (2) of the twenty-two (22) At-Risk Suppliers that we surveyed responded that they had completed their due diligence with respect to certain Conflict Minerals contained in the Components and Parts purchased by the Company from the supplier. All of the SORs identified by these two (2) At-Risk Suppliers are listed in Appendix A to this Report. All of the identified SORs listed in Appendix A were known by CFSI.

The Company believes that the SORs listed in Appendix A may have used to process Conflict Minerals contained in the Compressors. Based on the information provided by the Company’s suppliers, the identified SORs, and CFSI, the Company further believes that the countries of origin of the Conflict Minerals in the Compressors include some or all of the countries listed in Appendix B to this Report.

Only two (2) of the identified SORs-Malaysia Smelting Corporation and Thailand Smelting and Refining Co., Ltd. (“Thaisarco”)-were identified as sources of Conflict Minerals from the Covered Countries. All but one of the identified SORs-including Malaysia Smelting Corporation and Thaisarco-however, were determined to be compliant with the relevant CFSP assessment protocol. The remaining SOR-Fenix Metals-has committed to undergo a CFSP audit. The Company has found no reasonable basis for concluding that Fenix Metals sourced Conflict Minerals that directly or indirectly financed or benefitted armed groups in the Covered Countries.

Planned Risk Mitigation for 2015 Onwards

The Company expects to take the following steps, among others, to improve our due diligence measures and to further mitigate the risk that necessary Conflict Minerals contained in our products directly or indirectly finance or benefit armed groups in the Covered Countries:

| |

• | In-Scope Products and Suppliers |

| |

◦ | Compile and review the list of covered products manufactured or contracted to be manufactured by newly acquired company, Compressor Systems, Inc., and associated suppliers as needed. |

| |

◦ | Review and update the list of covered products manufactured or contracted to manufactured by CSI Compressco LP and associated suppliers as needed. |

| |

◦ | Consider the inclusion of contractual provisions within certain key supplier agreements requiring these suppliers to meet the standards set forth in our Conflict Minerals Policy. |

| |

◦ | Begin to engage with At-Risk Suppliers of Components and Parts used by newly acquired company, Compressor Systems, Inc., in its manufacturing of covered products to increase supply chain transparency. |

| |

◦ | Continue to engage with At-Risk Suppliers of Components and Parts used by CSI Compressco LP in its manufacturing of the Compressors to obtain current, accurate, complete, and usable information about the supply chain. Follow up with un-responsive suppliers and suppliers who provided incomplete information. Re-engage suppliers periodically to update changed or new sourcing information. Implement a process to communicate the Company’s Conflict Minerals Policy to new suppliers. |

| |

◦ | Continue to monitor and track suppliers against expectations set forth in the Company’s Conflict Minerals Policy. |

| |

◦ | Continue to encourage suppliers to establish policies, due diligence frameworks, and management systems consistent with OECD Guidance and to require their suppliers to do the same. |

| |

◦ | Continue to develop a Company Conflict Minerals database that will be a separate and special part of the Company’s records in which to collect and store information from suppliers and allow more effective analysis of the information in the database. |

Appendix A

| |

1. | List of the SORs which were compliant with the relevant CFSP assessment protocol and were identified through CSI Compressco LP’s supply chain. |

|

| | | | |

Metal | Smelter Reference List | Smelter Name | Smelter Country | CFSI Smelter I.D. Number |

Tin | Malaysia Smelting Corporation (MSC) | Malaysia Smelting Corporation (MSC) | MALAYSIA | CID001105 |

Tin | Minsur | Minsur | PERU | CID001182 |

Tin | PT Timah (Persero), Tbk | PT Timah (Persero), Tbk | INDONESIA | CID001482 |

Tin | Thailand Smelting & Refining Co., Ltd | Thaisarco | THAILAND | CID001898 |

Tin | EMPERESA METALURGICA VINTO | EM Vinto | BOLIVIA | CID000438 |

Tin | Yuntinic Resources | Yunnan Tin Company, Ltd. | CHINA | CID002180 |

Tin | Yunnan Tin Company, Ltd. | Yunnan Tin Company, Ltd. | CHINA | CID002180 |

Tin | EM Vinto | EM Vinto | BOLIVIA | CID000438 |

Tin | Gejiu Non-Ferrous Metal Processing Co. Ltd. | Gejiu Non-Ferrous Metal Processing Co. Ltd. | CHINA | CID000538 |

Tin | OMSA | OMSA | BOLIVIA | CID001337 |

Tin | PT Bangka Tin Industry | PT Bangka Tin Industry | INDONESIA | CID001419 |

Tin | PT Bukit Timah | PT Bukit Timah | INDONESIA | CID001428 |

Tin | PT Timah | PT Timah (Persero), Tbk | INDONESIA | CID001482 |

Tin | PT Tinindo Inter Nusa | PT Tinindo Inter Nusa | INDONESIA | CID001490 |

Tin | Taboca | Mineração Taboca S.A. | BRAZIL | CID001173 |

Tin | Thaisarco | Thaisarco | THAILAND | CID001898 |

Gold | Allgemeine Gold-und Silberscheideanstalt A.G. | Allgemeine Gold-und Silberscheideanstalt A.G. | GERMANY | CID000035 |

Gold | AngloGold Ashanti Córrego do Sítio Minerção | AngloGold Ashanti Córrego do Sítio Minerção | BRAZIL | CID000058 |

Gold | Argor-Heraeus SA | Argor-Heraeus SA | SWITZERLAND | CID000077 |

Gold | Chimet S.p.A. | Chimet S.p.A. | ITALY | CID000233 |

Gold | China's Shandong Gold Mining Co., Ltd | The Refinery of Shandong Gold Mining Co. Ltd | CHINA | CID001916 |

Gold | Heimerle + Meule GmbH | Heimerle + Meule GmbH | GERMANY | CID000694 |

Gold | Heraeus Precious Metals GmbH & Co. KG | Heraeus Precious Metals GmbH & Co. KG | GERMANY | CID000711 |

Gold | Johnson Matthey Ltd | Johnson Matthey Ltd | CANADA | CID000924 |

Gold | JM USA | Johnson Matthey Inc | UNITED STATES | CID000920 |

Gold | Materion | Materion | UNITED STATES | CID001113 |

Gold | Matsuda Sangyo Co., Ltd. | Matsuda Sangyo Co., Ltd. | JAPAN | CID001119 |

Gold | Metalor Switzerland | Metalor Technologies SA | SWITZERLAND | CID001153 |

Gold | Metalor Technologies (Hong Kong) Ltd | Metalor Technologies (Hong Kong) Ltd | HONG KONG | CID001149 |

Gold | Aurubis AG | Aurubis AG | GERMANY | CID000113 |

Gold | Shandong Zhaojin Gold & Silver Refinery Co. Ltd | Shandong Zhaojin Gold & Silver Refinery Co. Ltd | CHINA | CID001622 |

Gold | SMM | Sumitomo Metal Mining Co., Ltd. | JAPAN | CID001798 |

Gold | Tanaka Denshi Kogyo K.K | Tanaka Kikinzoku Kogyo K.K. | JAPAN | CID001875 |

Gold | Umicore SA Business Unit Precious Metals Refining | Umicore SA Business Unit Precious Metals Refining | BELGIUM | CID001980 |

Gold | Valcambi SA | Valcambi SA | SWITZERLAND | CID002003 |

|

| | | | |

Metal | Smelter Reference List | Smelter Name | Smelter Country | CFSI Smelter I.D. Number |

Gold | Zhongjin Gold Corporation Limited | Zhongyuan Gold Smelter of Zhongjin Gold Corporation | CHINA | CID002224 |

| |

2. | List of the SORs which were known by CFSI, have committed to undergo a CFSP audit, and were identified through CSI Compressco LP’s supply chain (CFS compliance SORs listed above were not included) |

|

| | | | |

Metal | Smelter Reference List | Smelter Name | Smelter Country | CFSI Smelter I.D. Number |

Tin | Fenix Metals | Fenix Metals | POLAND | CID000468 |

Appendix B

Australia

Bolivia

Brazil

China

Democratic Republic of Congo

Indonesia

Peru

Rwanda

South Africa

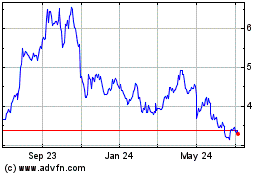

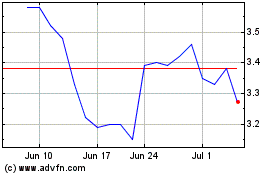

TETRA Technologies (NYSE:TTI)

Historical Stock Chart

From Aug 2024 to Sep 2024

TETRA Technologies (NYSE:TTI)

Historical Stock Chart

From Sep 2023 to Sep 2024