2014

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF

THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2014

OR

¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF

THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission file number 1-4119

NUCOR CORPORATION

(Exact name of registrant as specified in its charter)

|

|

|

| Delaware |

|

13-1860817 |

| (State or other jurisdiction of

incorporation or organization) |

|

(I.R.S. Employer Identification No.) |

|

|

| 1915 Rexford Road, Charlotte, North Carolina |

|

28211 |

| (Address of principal executive offices) |

|

(Zip Code) |

Registrant’s telephone number, including area code: (704) 366-7000

Securities registered pursuant to Section 12(b) of the Act:

|

|

|

| Title of each class |

|

Name of each exchange

on which

registered |

| Common stock, par value $0.40 per share |

|

New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities

Act. Yes x No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the

Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the

Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90

days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive

Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in

definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller

reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

|

|

|

|

|

|

|

| Large accelerated filer x |

|

Accelerated filer ¨ |

|

Non-accelerated filer ¨ |

|

Smaller reporting company ¨ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the

Act). Yes ¨ No x

Aggregate market value of common stock held by non-affiliates was approximately $16.04 billion based upon the closing sales price of the

registrant’s common stock on the last business day of the registrant’s most recently completed second fiscal quarter, July 5, 2014.

319,046,902 shares of the registrant’s common stock were outstanding at February 20, 2015.

Documents incorporated by reference include: Portions of the registrant’s 2014 Annual Report (Parts I, II and IV), and portions of the registrant’s Proxy Statement for its 2015 Annual Meeting of

Stockholders (Part III) to be filed within 120 days after the registrant’s fiscal year end.

Nucor Corporation

Table of Contents

i

PART I

Overview

Nucor Corporation and its affiliates (“Nucor,” the “Company” or “we”) manufacture steel and steel products.

The Company also produces direct reduced iron (“DRI”) for use in the Company’s steel mills. Through The David J. Joseph Company and its affiliates (“DJJ”), the Company also processes ferrous and nonferrous metals and brokers

ferrous and nonferrous metals, pig iron, hot briquetted iron (“HBI”) and DRI. Most of the Company’s operating facilities and customers are located in North America, but Nucor is doing business outside of North America as well. The

Company’s operations include several international trading companies that buy and sell steel and steel products manufactured by the Company and others.

Nucor is North America’s largest recycler, using scrap steel as the primary raw material in producing steel and steel products. In 2014, we recycled approximately 19.0 million tons of scrap

steel.

General Development of our Business in Recent Years

Nucor has invested significant capital in recent years to improve our cost structure and expand our product portfolios to include more value-added, higher margined offerings. Our investments total nearly

$6 billion during the last six years, with approximately two-thirds going to capital expenditures and one-third going to acquisitions. The Company believes that this focus on lowering cost will enable us to execute on our strategy of delivering

profitable growth and expanding our product mix and market diversity will make us less susceptible to imports.

A major

emphasis of our cost improvement plan is on reducing our raw materials cost. We have a goal of controlling between six and seven million tons of annual capacity in high-quality scrap substitutes so that we can better control both the cost and

reliable sourcing of these raw materials. Our 2,500,000 metric tons-per-year DRI facility in St. James Parish, Louisiana began production in December 2013. Between the DRI plant in Trinidad with an annual capacity of 2,000,000 metric tons and our

new facility in Louisiana, we will be approximately two-thirds of the way towards that goal when the Louisiana facility is fully operational. Our DRI plant in St. James Parish, Louisiana produced excellent quality DRI through the first ten

months of 2014. However, the plant experienced operational challenges in 2014 as it went through several outages to make changes intended to improve consistency in the production process and yield performance. In November, the plant’s process

gas heater experienced a failure, leading to the immediate suspension of production operations. Due to the lead times on the specialty steel pipes that must be replaced, we estimate that the Louisiana DRI plant will be operational again late in the

first quarter of 2015.

The DRI production process requires significant volumes of natural gas. To ensure the DRI plant in

Louisiana has a sustained advantage from lower natural gas costs, Nucor entered into two long-term, onshore natural gas working interest drilling programs in U.S.-based proven reserves with Encana Oil & Gas (USA) Inc. (“Encana”)

that allow us to better manage our exposure to natural gas pricing volatility and our overall energy demand for our operations. The natural gas produced by these two programs is sold to third parties to offset our exposure to the volatility of the

price of natural gas consumed by the Louisiana DRI facility and our other operations. In December 2013, Nucor made a joint decision with Encana to temporarily suspend drilling new natural gas wells. The joint decision was made due to the

then-current expectation that the natural gas pricing environment would be weak in 2014. In the fourth quarter of 2014, Nucor and Encana agreed to further suspend drilling through calendar year 2015, except for a de minimis number of wells that are

necessary in order to retain leasehold rights. We believe this joint decision demonstrates the flexibility of our partnership with Encana to react to market conditions to the mutual benefit of both parties while still allowing us to better manage

our exposure to natural gas pricing volatility at our operating divisions that consume natural gas.

Of the approximately $4

billion that has been spent since 2009 on capital expenditures, the main focus of that spending has been on projects that further our raw materials and value-added product diversification

1

strategies. Within the steel mills segment, Nucor has deployed significant amounts of capital to expand our product offerings, enhance productivity and improve costs at our existing operations.

At our Hertford County, North Carolina plate mill, the heat treat line became operational in 2011, which has allowed Nucor to grow its presence in higher-margin products where greater strength and abrasion resistance is required. The heat treat line

allows us to improve the product mix allocation between our two plate mills and five sheet mills to improve margins at those facilities. Also at the Hertford County mill, we commissioned a vacuum tank degasser in 2012, and we began operating a

normalizing line in 2013. Collectively, these investments have positioned the Hertford County mill to increase the diversity of our product offerings that are less exposed to imports. Nucor’s $290 million project at our Tennessee, Nebraska and

South Carolina bar mills to expand our special bar quality (“SBQ”) and wire rod production capabilities by approximately one million tons is nearing completion. Production has begun on the new wire rod mill located in South Carolina, and

our Nebraska mill successfully started up the fifth strand at its melt shop caster and its upgraded rolling mill. Our Tennessee mill added a second ladle metallurgy furnace, a fourth strand at its melt shop caster and a new quality assurance line.

The SBQ projects, which we expect to be completed in 2015, will allow us to produce engineered bar for more demanding applications that are less exposed to imports while maintaining our position as a low-cost commodity bar producer by shifting

production to our other bar mills. In 2014, our Berkeley County, South Carolina mill successfully started up its nearly $100 million capital project that allows us to produce wider and thinner high-strength steel grades that can be used in

lightweight automotive applications.

Nucor’s steel mills segment has also grown significantly in recent years through

the acquisitions of Gallatin Steel Company (“Gallatin”) and Skyline Steel LLC (“Skyline”). Nucor acquired Gallatin in 2014 for a cash purchase price of $779 million. Located on the Ohio River in Ghent, Kentucky, Gallatin has an

annual sheet steel production capacity of approximately 1,800,000 tons. This acquisition is strategically important as it expands Nucor’s footprint in the Midwestern United States market, and it broadens Nucor’s product offerings in the

pipe and tube market. The acquisition of Skyline in 2012 for $675 million was an important strategic investment as it paired Skyline’s leadership position in the steel piling distribution market with our Nucor-Yamato Steel Company

(“Nucor-Yamato”) joint venture’s position as the market leader in steel piling manufacturing. To build upon the synergies in the piling market serviced by Skyline, Nucor-Yamato has invested $115 million in a project to broaden its

range of hot-rolled piling products. Completed in the second half of 2014, this project added several new sheet piling sections, which expanded our product offerings to include wider piling sections that are lighter and stronger, covering more area

at a lower installed cost.

Segments

Nucor reports its results in three segments: steel mills, steel products and raw materials. Net sales to external customers, intercompany sales, depreciation expense, amortization expense, earnings before

income taxes and noncontrolling interests, assets and capital expenditures by segment for each of the three fiscal years in the three-year period ended December 31, 2014 are set forth in Note 23 of the Notes to Consolidated Financial Statements

included in Nucor’s 2014 Annual Report, which is incorporated by reference. The steel mills are Nucor’s largest segment, representing approximately 70% of the Company’s sales to external customers in the fiscal year ended

December 31, 2014.

Principal Products Produced

In the steel mills segment, Nucor produces and distributes sheet steel (hot-rolled, cold-rolled and galvanized), plate steel, structural steel (wide-flange beams, beam blanks, H-piling and sheet piling)

and bar steel (blooms, billets, concrete reinforcing bar, merchant bar, wire rod and SBQ). Nucor manufactures steel principally from scrap steel and scrap steel substitutes using electric arc furnaces, continuous casting and automated rolling mills.

Nucor’s equity method investments in Duferdofin Nucor S.r.l. and NuMit LLC are included in the steel mills segment. Also included in the steel mills segment are our distribution and international trading companies that buy and sell steel and

steel products that Nucor and other steel producers have manufactured. In the steel products segment, Nucor produces steel joists and joist girders, steel deck, fabricated concrete reinforcing steel,

2

cold finished steel, steel fasteners, metal building systems, steel grating and expanded metal, and wire and wire mesh. In the raw materials segment, the Company produces DRI; brokers ferrous and

nonferrous metals, pig iron, HBI and DRI; supplies ferro-alloys; and processes ferrous and nonferrous scrap metal. The raw materials segment also includes our natural gas working interest drilling programs with Encana and Nucor’s equity method

investment in Hunter Ridge Energy Services LLC.

Markets and Marketing

The steel mills segment sells its products primarily to steel service centers, fabricators and manufacturers located throughout the United

States, Canada, Mexico and elsewhere in the world. Nucor produces hot-rolled, cold-rolled and galvanized sheet steel in standard grades and to customers’ specifications while maintaining inventories to fulfill anticipated orders. We estimate

that approximately 50% of our sheet steel sales in 2014 were to contract customers. The balance of our sheet steel sales was made in the spot market at prevailing prices at the time of sale. The proportion of tons sold to contract customers at any

given time depends on a variety of factors, including our consideration of current and future market conditions, our strategy to appropriately balance spot and contract tons to maximize profitability, our desire to sustain a diversified customer

base, and our end-use customers’ perceptions about future market conditions. These sheet sales contracts permit price adjustments to reflect changes in the current market-based indices and/or raw material costs near the time of shipment. These

sheet sales contracts typically have terms ranging from six to twelve months. Steel contract sales outside of our sheet operations are not significant.

Our plate, structural, reinforcing and merchant bar steel come in standard sizes and grades, which allows us to maintain inventory levels of these products to meet our customers’ expected orders. In

addition, our bar mill group manufactures hot-rolled SBQ products to exacting specifications primarily servicing the automotive, energy, agricultural, heavy equipment and transportation sectors. Almost all of our plate, structural, rebar, merchant

bar and SBQ steel sales occur in the spot market at prevailing market prices.

In 2014, approximately 85% of the shipments

made by our steel mills segment were to external customers. The balance of the steel mills segment’s shipments went to our piling distributor and our downstream joist, deck, rebar fabrication, fastener, metal buildings and cold finish

operations.

In the steel products segment, we sell steel joists and joist girders, and steel deck to general contractors and

fabricators located throughout the United States and Canada. We make these products to the customers’ specifications and do not maintain inventories of these finished steel products. The majority of these contracts are firm, fixed-price

contracts that are in most cases competitively bid against other suppliers. Longer-term supply contracts may or may not permit us to adjust our prices to reflect changes in prevailing raw materials costs. We sell and install fabricated reinforcing

products only on a construction contract bid basis. These products are used by contractors in constructing highways, bridges, reservoirs, utilities, hospitals, schools, airports, stadiums and high-rise buildings. We manufacture cold finished steel,

steel fasteners, steel grating, wire and wire mesh in standard sizes and maintain inventories of these products to fulfill anticipated orders. We sell cold finished steel and steel fasteners primarily to distributors and manufacturers located

throughout the United States and Canada.

We market products from the steel mills and steel products segments mainly through

in-house sales forces. We also utilize our internal distribution and trading companies to market our products abroad. The markets for these products are largely tied to capital and durable goods spending and are affected by changes in general

economic conditions.

In the raw materials segment, we process ferrous and nonferrous scrap metal for use in our steel mills

and for sale to various domestic and international external customers. We also broker ferrous and nonferrous metals and scrap substitutes, supply ferro-alloys, and provide transportation, material handling and other services to users of scrap

metals. Our primary external customers for ferrous scrap are electric arc furnace steel mills and foundries that use ferrous scrap as a raw material in their manufacturing process. External customers purchasing nonferrous scrap metal include

aluminum can producers, secondary aluminum smelters, steel mills and other

3

processors and consumers of various nonferrous metals. We market scrap metal products and related services to our external customers through in-house sales forces. In 2014, approximately 14% of

the ferrous and nonferrous metals and scrap substitutes tons we processed were sold to external customers. We used the balance in our steel mills.

Also within the raw materials segment are our DRI plants in Trinidad and Louisiana that produce iron inputs exclusively for use in the Nucor mills, as well as our natural gas working interest drilling

programs. All natural gas produced by the working interest drilling programs is and will be sold to outside parties, and as a result the revenues from these sales are a small but increasing amount of our revenues.

Backlog

In the steel

mills segment, Nucor’s backlog of orders was approximately $1.56 billion and $1.77 billion at December 31, 2014 and 2013, respectively. Order backlog for the steel mills segment includes only orders from external customers and excludes

orders from our downstream businesses. Nucor’s backlog of orders in the steel products segment was approximately $1.49 billion and $1.27 billion at December 31, 2014 and 2013, respectively. The majority of these orders will be filled

within one year. Order backlog within our raw materials segment is not significant because the majority of the raw materials that segment produces are used internally.

Sources and Availability of Raw Materials

The primary raw materials for

our steel mills segment are ferrous scrap and scrap substitutes such as pig iron, DRI and HBI. On average, it takes approximately 1.1 tons of scrap and scrap substitutes to produce a ton of steel. As of December 31, 2014, DJJ operated over 70

scrap recycling facilities, and our annual scrap processing capability exceeded five million tons. DJJ acquires ferrous scrap from numerous sources including manufacturers of products made from steel, industrial plants, scrap dealers, peddlers, auto

wreckers and demolition firms. We purchase pig iron as needed from a variety of sources and operate DRI plants in Trinidad and Louisiana with respective capacities of 2,000,000 and 2,500,000 metric tons annually. The primary raw material for our DRI

facilities is iron ore, which we purchase from various international suppliers. Our newly constructed Louisiana DRI facility is the first phase of a multi-phase site development plan opportunity in Louisiana.

In 2010, Nucor entered into an agreement with Encana that involves drilling and completing onshore natural gas wells in U.S.-based proven

reserves over an approximate seven-year period that began in June 2010. Nucor entered into a second and more extensive drilling agreement with Encana in late 2012 that is projected to span more than 20 years. Natural gas produced by these working

interest drilling programs is being sold to offset our exposure to the volatility of the price of natural gas consumed by our Louisiana DRI facility and our other operations. In December 2013, Nucor and Encana announced an agreement to temporarily

suspend drilling new natural gas wells due to the then-current expectations that the natural gas pricing environment would be weak in 2014. In the fourth quarter of 2014, Nucor and Encana agreed to extend our drilling suspension through the end of

2015. The 2015 capital expenditures for drilling will consist of drilling a de minimis number of wells required to maintain leasehold rights. Under the agreement with Encana, Nucor maintains the right to resume drilling at any point should natural

gas prices change. In addition to our natural gas needs at the Louisiana DRI facility, Nucor is also a substantial consumer of natural gas at our steel mill operations. The drilling of natural gas wells under the two agreements is expected to be

sufficient in the future to cover Nucor’s demand at all of its steel mills in the United States plus the demand of two DRI plants or, alternatively, at three DRI plants, if additional capacity were to be added.

The primary raw material for our steel products segment is steel produced by Nucor’s steel mills.

DJJ generally purchases ferrous and nonferrous scrap for sale to external customers from the same variety of sources it purchases ferrous

scrap for use as a raw material in Nucor’s steel mills. DJJ does not purchase a significant amount of scrap metal from a single source or from a limited number of major sources. The

4

availability and price of ferrous scrap are affected by changes in the global supply and demand for steel and steel products. Ferrous scrap and scrap substitutes are our single largest cost of

products sold. A key part of our business strategy is to control a significant portion of the supply of high quality metallics needed to operate our steel mills.

Energy Consumption and Costs

Our steel mills are large consumers of

electricity and natural gas. Our DRI facilities in Trinidad and Louisiana are also large consumers of natural gas. Consequently, we use a variety of strategies to manage our exposure to price risk of natural gas, including cash flow hedges and our

natural gas working interest drilling programs.

Historically, manufacturers in the United States have benefited from

relatively stable and competitive energy costs that have allowed them to compete on an equal footing in the increasingly global marketplace. The availability and prices of electricity and natural gas are influenced today, however, by many factors

including changes in supply and demand, advances in drilling technology and, increasingly, changes in public policy relating to energy production and use. Because energy is such a significant cost of products sold for Nucor, we strive continually to

make our operations in all three of our business segments more energy efficient. We also closely monitor developments in public policy relating to energy production and consumption. When appropriate, we work to shape those developments in ways that

we believe will allow us to continue to be a competitive producer of steel and steel products in an increasingly competitive global marketplace.

Competition

We compete in a variety of steel and metal markets, including

markets for finished steel products, unfinished steel products and raw materials. These markets are highly competitive with many domestic and foreign firms participating, and, as a result of this highly competitive environment, we find that we

primarily compete on price and service.

Our electric arc furnace steel mills face many different forms of competition,

including integrated steel producers (who use iron ore converted into liquid form in a blast furnace as their basic raw material instead of scrap steel), other electric arc furnace mills, foreign imports and alternative materials. Large integrated

steel producers have the ability to manufacture a wide variety of products but face significantly higher energy costs and are often burdened with higher capital and fixed operating costs. Electric arc furnace mill producers such as Nucor are

sensitive to increases in scrap prices but tend to have lower capital and fixed operating costs compared with integrated steel producers.

Overproduction in global steelmaking capacity continues to be a significant challenge for Nucor and the entire U.S. steel industry. With the U.S. economy performing better than most other economies

around the world, the U.S. steel market is the destination of choice for global steel producers. In 2014, total steel imports increased 38% compared with 2013, and imports of finished and semi-finished steel products accounted for 34% of U.S.

market share last year. Imports increased from nearly every steel-producing country and in virtually every category of steel products. These imports, which are sometimes artificially-priced, make it very difficult for Nucor to maintain sales prices

and profit levels.

Competition from foreign steel and steel product producers presents unique challenges for us. Imported

steel and steel products often benefit from government subsidies, either directly or indirectly through government-owned enterprises or government-owned or controlled financial institutions. China, which accounts for almost half of the steel

produced annually in the world, is the prime example of how foreign governments impact the global steel market. Nucor believes that Chinese producers, many of which are government-owned in whole or in part, benefit from their government’s

manipulation of foreign currency exchange rates and from the receipt of government subsidies, which allow them to sell their products below cost. Other foreign governments utilize similar tactics to artificially lower their steel production costs.

These distorting trade practices are widely

5

recognized as being unfair and have been challenged successfully as violating world trade rules. The U.S. government recently completed several successful trade enforcement actions, including

terminating its suspension agreement with Russia for hot-rolled steel imports; assessing duties on oil country tubular goods from South Korea and five other countries; and ruling that the domestic rebar industry has been materially injured as a

result of dumped and subsidized rebar imports from Turkey and Mexico.

Aggressive trade practices, left unchallenged,

seriously undermine the ability of Nucor and other domestic producers to compete on price. Competition from countries with subsidized production costs has significantly contributed to the exodus of manufacturing jobs from the United States. When

such an exodus occurs, the U.S. economy is weakened and Nucor’s customer base is diminished. Rigorous trade law enforcement is critical to our ability to maintain our competitive position against foreign producers that engage in unlawful trade

practices. Nucor has been active in calling on policymakers to enforce global trade agreements.

We also experience

competition from other materials. Depending on our customers’ end use of our products, there are sometimes other materials, such as concrete, aluminum, plastics, composites and wood that compete with our steel products. When the price of steel

relative to other raw materials rises, these alternatives become more attractive to our customers.

Competition in our scrap

and raw materials business is also vigorous. The scrap metals market consists of many firms and is highly fragmented. Firms typically compete on price and geographic proximity to the sources of scrap metal.

Environmental Laws and Regulations

Our business operations are subject to numerous federal, state and local laws and regulations intended to protect the environment. The principal federal environmental laws include the Clean Air Act

(“CAA”) that regulates air emissions; the Clean Water Act (“CWA”) that regulates water discharges; the Resource Conservation and Recovery Act (“RCRA”) that addresses solid and hazardous waste treatment, storage and

disposal; and the Comprehensive Environmental Response, Compensation and Liability Act (“CERCLA”) that governs releases of, and remediation of, sites contaminated by hazardous substances. Our operations are also subject to state laws and

regulations that are patterned on these and other federal laws.

We believe that we are in substantial compliance with the

provisions of all federal and state environmental laws and regulations applicable to our business operations. However, both federal and state laws and regulations are becoming increasingly stringent, making compliance with them increasingly

expensive and burdensome. In many instances the total costs of compliance are not readily quantifiable because compliance is so engrained in our operating philosophy that these costs are simply considered part of our standard operating procedures.

The United States Environmental Protection Agency (“USEPA”) has proposed or promulgated many new national ambient

air quality standards and toxic air emissions rules for which it has recently or not yet issued guidance or compliance deadlines. While we begin immediately to plan for compliance with such standards and rules, we cannot fully assess their impact on

our operations until the guidance has been fully developed or issued and compliance deadlines have been established. In other cases where environmental regulations are proposed or promulgated that may regulate previously unregulated aspects of our

operations, it is impossible for us to fully determine the impact of these regulations until protracted legal challenges have been concluded and USEPA or other regulatory agencies have developed and issued technical guidance. Despite this atmosphere

of regulatory uncertainty, at this time we do not believe that compliance with these new environmental regulations will have a material adverse effect on our results of operations, cash flows or financial condition.

The CAA imposes stringent limits on air emissions with a federally mandated operating permit program administered by the states with

civil and criminal enforcement sanctions. Each of our steel mills is required to operate in compliance with its permit or potentially incur sanctions for failing to do so. Because of the size of our steelmaking operations, they are subject to new

“Greenhouse Gasses” (“GHGs”) regulations and are required to

6

do GHG Best Available Control Technology (“BACT”) evaluations when their permits are modified. There is still uncertainty and very little guidance from USEPA as to what is or may be

considered GHG BACT for steelmaking operations. Our operations are currently properly permitted, and we will not need to make these determinations unless and until these permits are modified. Based on current guidance, we do not expect these

requirements to have a material adverse effect on our results of operations, cash flows or financial condition.

Nucor uses

electric arc furnaces (“EAF”) to recycle scrap metal into new steel products. These EAFs use electricity as their primary source of energy. As the new GHG regulations, air toxics rules and new emissions standards recently imposed on

electric utilities are fully implemented it is reasonable to expect that the cost of electricity produced by these utilities will increase. See Item 1A “Risk Factors” for more information about the potential impact of GHG regulations

on Nucor’s business.

The CWA regulates water discharges and withdrawals. Nucor maintains discharge and withdrawal

permits as appropriate at its facilities under the national pollutant discharge elimination system program of the CWA and conducts its operations in compliance with those permits. Nucor also maintains permits from local governments for the discharge

of water into publicly owned treatment works where available.

RCRA establishes standards for the management of solid and

hazardous wastes. RCRA also addresses the environmental impact of contamination from waste disposal activities and from recycling of and storage of most wastes. While Nucor believes it is in substantial compliance with these regulations, past waste

disposal activities that were legal when conducted but now may pose a contamination threat are periodically discovered. These and off-site properties that USEPA has determined are contaminated, for which Nucor may be potentially responsible at some

level, are quickly evaluated and corrected. While Nucor has conducted and is in the final stages of completing some cleanups under RCRA, these liabilities either are identified already and being resolved or have been fully resolved.

Because Nucor long ago implemented environmental practices that have resulted in the responsible disposal of waste materials, Nucor is

also not presently considered a major contributor to any major cleanups under CERCLA for which Nucor has been named a potentially responsible party. Nucor continually evaluates these types of potential liabilities and, if appropriate, maintains

reserves sufficient to remediate the identified liabilities. Under RCRA, private citizens may also bring an action against the operator of a regulated facility for potential damages and payment of cleanup costs. Nucor is confident that its system of

internal evaluation and due diligence has sufficiently identified these types of potential liabilities so that compliance with these regulations will not have a material adverse effect on our results of operations, cash flows or financial condition

beyond that already reflected in the reserves established for them.

The primary raw material of Nucor’s steelmaking

operations is scrap metal. The process of recycling scrap metal brings with it many contaminants such as paint, zinc, chrome and other metals that produce air emissions which are captured in specialized emission control equipment. This filtrant (EAF

dust) is classified as a listed hazardous waste under the RCRA. Because these contaminants contain valuable metals, this filtrant is recycled to recover those metals. Nucor sends all but a small fraction of the EAF dust it produces to recycling

facilities that recover the zinc, lead, chrome and other valuable metals from this dust. By recycling this material, Nucor is not only acting in a sustainable, responsible manner but is also substantially limiting its potential for future liability

under both CERCLA and RCRA.

Nucor operates an aggressive and sustainable environmental program that incorporates the concept

of individual employee as well as management responsibility for environmental performance. All of Nucor’s steelmaking operations are ISO 14001 certified. Achieving ISO 14001 certification means that each of Nucor’s steel mills has put an

environmental management system in place with measurable targets and objectives, such as reducing the use of oil and grease and minimizing electricity use, and has implemented site-wide recycling programs. These environmental management systems make

environmental commitment each Nucor teammate’s responsibility. Nucor’s environmental program maintains a high level of training, commitment, outreach and visibility.

7

Capital expenditures at our facilities that are associated with environmental regulation

compliance for 2015 and 2016 are estimated to be less than $100 million per year.

Employees

Nucor has a simple, streamlined organizational structure to allow our employees to make quick decisions and to innovate. Our organization

is highly decentralized, with most day-to-day operating decisions made by our division general managers and their staff. We have slightly more than 100 employees in our executive office. The vast majority of Nucor’s 23,600 employees are not

represented by labor unions.

Available Information

Nucor’s annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and any amendments to these reports, are available on our website at www.nucor.com, as soon as

reasonably practicable after Nucor files these reports electronically with, or furnishes them to, the Securities and Exchange Commission (“SEC”). Except as otherwise stated in these reports, the information contained on our website or

available by hyperlink from our website is not incorporated into this Annual Report on Form 10-K or other documents we file with, or furnish to, the SEC.

Many of the

factors that affect our business and operations involve risk and uncertainty. The factors described below are some of the risks that could materially negatively affect our business, financial condition and results of operations.

Our industry is cyclical and both recessions and prolonged periods of slow economic growth could have an adverse effect on our business.

Demand for most of our products is cyclical in nature and sensitive to general economic conditions. Our business supports

cyclical industries such as the commercial construction, energy, metals service centers, appliance and automotive industries. As a result, downturns in the United States economy or any of these industries could materially adversely affect our

results of operations, financial condition and cash flows. Five years removed from the worst recession the United States has experienced in decades, we have begun to see some improvement in general economic and manufacturing activity. However, the

slow pace of recovery, coupled with ongoing uncertainties in Europe and other regions of the world, continue to weigh on global and domestic growth. These situations continue to contribute to weaker end-markets and depressed demand, resulting in

extraordinary volatility in our financial results.

Although we experienced increased profitability in 2014 from the previous

year, the economic outlook remains uncertain both in the United States and globally. While we believe that the long-term prospects for the steel industry remain bright, we are unable to predict the duration of the current economic conditions that

are contributing to reduced demand for our products compared to pre-recession levels. Future economic downturns or a prolonged slow-growth or stagnant economy could materially adversely affect our business, results of operations, financial condition

and cash flows.

Overcapacity in the global steel industry could increase the level of steel imports, which may negatively affect our

business, results of operations and cash flows.

Global steelmaking capacity exceeds global consumption of steel products.

During periods of global economic weakness this overcapacity is amplified because of weaker global demand. This excess capacity often results in manufacturers in certain countries exporting significant amounts of steel and steel products at prices

that are at or below their costs of production. In some countries the steel industry is subsidized or owned in whole or in part by the government, giving imported steel from those countries certain cost advantages. These imports, which are also

affected by demand in the domestic market, international currency conversion rates and

8

domestic and international government actions, can result in downward pressure on steel prices, which could materially adversely affect our business, results of operations, financial condition

and cash flows. Overcapacity has also led to greater protectionism as is evident in raw material and finished product border tariffs put in place by China, Brazil and other countries.

In particular, steel production in China, the world’s largest producer and consumer of steel, continues to exceed Chinese demand.

This rising overcapacity in China has resulted in a further increase in imports of artificially low-priced steel and steel products to the United States and world steel markets. Steel and steel products which would otherwise have been consumed by

the local steel customers could then be displaced into global markets, putting our steel and steel products at a competitive disadvantage. A continuation of this unbalanced growth trend or a significant decrease in China’s rate of economic

expansion could result in increasing steel exports from China.

Producers in the world steel market could pursue additional

export opportunities as a result of the current abundance of ocean freight capacity and lower fuel costs. However, the domestic steel market could experience a contraction in exports at the same time as imports grow due to weakening conditions in

Europe and policies of foreign governments that result in overvaluing the U.S. dollar against other foreign currencies. Furthermore, the planned addition of new capacity in the United States could exacerbate the issue of overcapacity domestically as

well as globally.

Competition from other producers, imports or alternative materials may adversely affect our business.

We face strong competition from other steel producers and imports that compete with our products on price and service. The steel markets

are highly competitive and a number of firms, domestic and foreign, participate in the steel and raw materials markets. Depending on a variety of factors, including raw materials cost and availability, energy, technology, labor and capital costs,

government control of currency exchange rates and government subsidies of foreign steel producers, our business may be materially adversely affected by competitive forces.

In many applications, steel competes with other materials, such as concrete, aluminum, composites, plastic and wood. Increased use of these materials in substitution for steel products could have a

material adverse effect on prices and demand for our steel products.

Since 2011, automobile producers have begun taking steps

towards complying with new Corporate Average Fuel Economy mileage requirements for new cars and light trucks that they produce. As automobile producers work to produce vehicles in compliance with these new standards, they may reduce the amount of

steel or begin utilizing alternative materials in cars and trucks to improve fuel economy, thereby reducing demand for steel and resulting in further over-supply of steel in North America. Certain automakers have begun to use greater amounts of

aluminum and smaller proportions of steel in some 2015 and 2016 models.

The results of our operations are sensitive to volatility in steel

prices and the cost of raw materials, particularly scrap steel.

We rely to an extent on outside vendors to supply us with

raw materials, including both scrap and scrap substitutes that are critical to the manufacture of our products. Although we have further vertically integrated our business by constructing our DRI facilities in Trinidad and Louisiana and also

acquiring DJJ, we still must purchase most of our primary raw material, steel scrap, from numerous other sources located throughout the United States. Although we believe that the supply of scrap and scrap substitutes is adequate to operate our

facilities, prices of these critical raw materials are volatile and are influenced by changes in scrap exports in response to changes in the scrap demands of our global competitors. At any given time, we may be unable to obtain an adequate supply of

these critical raw materials with price and other terms acceptable to us. The availability and prices of raw materials may also be negatively affected by new laws and regulations, allocation by suppliers, interruptions in production, accidents or

natural disasters, changes in exchange rates, worldwide price fluctuations, and the availability and cost of transportation. Many countries that export steel into our

9

markets restrict the export of scrap, protecting the supply chain of some foreign competitors. This trade practice creates an artificial competitive advantage for foreign producers that could

limit our ability to compete in the U.S. market.

If our suppliers increase the prices of our critical raw materials, we may

not have alternative sources of supply. In addition, to the extent that we have quoted prices to our customers and accepted customer orders for our products prior to purchasing necessary raw materials, we may be unable to raise the price of our

products to cover all or part of the increased cost of the raw materials. Also, if we are unable to obtain adequate and timely deliveries of our required raw materials, we may be unable to timely manufacture sufficient quantities of our products.

This could cause us to lose sales, incur additional costs and suffer harm to our reputation.

Changes in the availability and cost of

electricity and natural gas are subject to volatile market conditions that could adversely affect our business.

Our steel

mills are large consumers of electricity and natural gas. In addition, our DRI facilities are also large consumers of natural gas. We rely upon third parties for our supply of energy resources consumed in the manufacture of our products. The prices

for and availability of electricity, natural gas, oil and other energy resources are subject to volatile market conditions. These market conditions often are affected by weather, political and economic factors beyond our control, and we may be

unable to raise the price of our products to cover increased energy costs. Disruptions in the supply of our energy resources could temporarily impair our ability to manufacture our products for our customers. Increases in our energy costs resulting

from regulations that are not equally applicable across the entire global steel market could materially adversely affect our business, results of operations, financial condition and cash flows.

A substantial or extended decline in natural gas prices could have a material adverse effect on our natural gas working interest drilling programs.

The financial performance and condition of our natural gas working interest drilling programs are substantially dependent

on the prevailing prices of natural gas and liquids. Fluctuations in natural gas or liquids prices could have an adverse effect on the Company’s natural gas operations and financial condition and the value and recovery of its reserves in the

working interest drilling programs. Prices for natural gas and liquids fluctuate in response to changes in the supply and demand for natural gas and oil, market uncertainty and a variety of additional factors beyond the Company’s control. A

substantial or extended decline in the price of natural gas could result in further delay or cancellation of existing or future drilling programs or curtailment in production at some properties, all of which could have an adverse effect on the

Company’s revenues, profitability and cash flows.

Our steelmaking processes, DRI processes, and the manufacturing processes of many

of our suppliers, customers and competitors are energy intensive and generate carbon dioxide and other GHGs. The regulation of these GHGs through new regulations or legislation in an onerous form could have a material adverse impact on our

results of operations, financial condition and cash flows.

Carbon is an essential raw material in Nucor’s production

processes. As a carbon steel producer, Nucor will be increasingly affected both directly and indirectly if GHG regulations are further implemented. Because our operations are subject to most of these new GHG regulations, we have already

begun to feel the impact in the permit modification and reporting processes. Both GHG regulations and recently promulgated National Ambient Air Quality Standards (“NAAQS”), which are more restrictive than previous standards, make it

significantly more difficult to obtain new permits and to modify existing permits.

These same regulations have indirectly

increased the costs to manufacture our products as they have and continue to increase the cost of energy, primarily electricity, which we use extensively in the steelmaking process. The discovery of new natural gas reserves utilizing the

practice of horizontal drilling and hydraulic fracturing is dampening some of this indirect impact, as some utilities switch fuels to natural gas from coal

10

thereby reducing their emissions significantly. However, because some generating facilities when faced with new regulations are idling facilities instead of converting to natural gas, the

resulting reduction in capacity can and will create further pressure on electrical energy prices. To the extent that these regulations cause either directly or indirectly an increase in the cost of energy, they will have an impact on

Nucor’s ability to compete.

The USEPA continues to press forward with new regulations that control GHG and other NAAQS

pollutants. Court challenges regarding many of these regulations have diminished to some extent their impact on various operations. Nucor operations have not, however, experienced any relief from these legal actions. Further court

challenges to some of the NAAQS revisions may affect our operations, but the impact is likely to be minimal. Because some foreign steel producers are not subject to these same indirect and direct regulatory burdens and their associated cost

increases, our products could be at a further competitive disadvantage. In addition to increased costs of production, we could also incur costs to defend and resolve legal claims and other litigation related to new air and water quality

regulations and the alleged impact of our operations on the environment.

Environmental compliance and remediation could result in

substantially increased costs and materially adversely impact our competitive position.

Our operations are subject to

numerous federal, state and local laws and regulations relating to protection of the environment, and we accordingly, make provision in our financial statements for the estimated costs of compliance. These laws are becoming increasingly

stringent, resulting in inherent uncertainties in these estimates. To the extent that competitors, particularly foreign steel producers and manufacturers of competitive products, are not subject to similar regulation and required to incur

equivalent costs, our competitive position could be materially adversely impacted. If one of our permits is revoked or if we were to experience significant delays in obtaining a permit modification or a new permit, this could result in

operational delays at one or more of our facilities, causing a negative impact on our results of operations and cash flows.

Federal and

state legislation and regulatory initiatives relating to hydraulic fracturing could result in increased costs and additional operating restrictions or delays.

Various legislative efforts, at all levels, are in process that are intended to further regulate the hydraulic fracturing process used by the oil and gas industry. Hydraulic fracturing is an important and

commonly used process in the completion of natural gas wells in shale and tight sand formations, including all of those in our natural gas working interest drilling programs. This process involves the injection of water, chemicals and, at times,

sand under pressure into rock formations to stimulate the release of natural gas, oil and natural gas liquids. Sponsors of these proposals and regulations have asserted that chemicals used in the fracturing process could adversely affect drinking

water supplies and/or that hydraulic fracturing could pose a variety of other risks. The practitioners of fracking are adamant that these claims are false and to date the USEPA has not attempted to further regulate the practice. Any onerous

governmental regulations could lead to operational delays, increased operating costs that could make it more difficult to perform hydraulic fracturing and possibly even the cessation of drilling.

We acquire businesses from time to time and we may encounter difficulties in integrating businesses we acquire.

We plan to continue to seek attractive opportunities to acquire businesses, enter into joint ventures and make other investments that

strengthen Nucor. Realizing the anticipated benefits of acquisitions or other transactions will depend on our ability to operate these businesses and integrate them with our operations and to cooperate with our strategic partners. Our business,

results of operations, financial condition and cash flows could be materially adversely affected if we are unable to successfully integrate these businesses.

11

Our operations are subject to business interruptions and casualty losses.

The steelmaking business is subject to numerous inherent risks, particularly unplanned events such as explosions, fires, other accidents,

natural disasters such as floods or earthquakes, unplanned critical equipment failures, acts of terrorism, inclement weather and transportation interruptions. While our insurance coverage could offset losses relating to some of those types of

events, our results of operations and cash flows could be adversely impacted to the extent any such losses are not covered by our insurance.

We are subject to information technology and cyber security threats which could have an adverse effect on our business.

We utilize various information technology systems to efficiently address business functions ranging from the operation of our production

equipment to administrative computation to the storage of data such as intellectual property and proprietary business information. Despite efforts to assure secure and uninterrupted operations, threats from increasingly sophisticated cyber-attacks

or system failures could result in materially adverse operational disruptions or security breaches. While decentralization tends to compartmentalize exposure, these risks could result in disclosure or destruction of key proprietary information and

reputational damage that could adversely affect our results of operations.

Our business requires substantial capital investment and

maintenance expenditures, and our capital resources may not be adequate to provide for all of our cash requirements.

Our

operations are capital intensive. For the five-year period ended December 31, 2014, our total capital expenditures, excluding acquisitions, were approximately $3.61 billion. Our business also requires

substantial expenditures for routine maintenance. Although we expect requirements for our business needs, including the funding of capital expenditures, debt service for financings and any contingencies, will be financed by internally generated

funds or from borrowings under our $1.5 billion unsecured revolving credit facility, we cannot assure you that this will be the case. Additional acquisitions or unforeseen events could require financing from additional sources.

Risks associated with operating in international markets could adversely affect our business, financial position and results of operations.

Certain of our businesses are located outside of the United States, in Europe and in emerging markets. There are a number

of risks inherent in doing business in such markets. These include but are not limited to: unfavorable political or economic factors; local labor and social issues; changes in regulatory requirements; fluctuations in foreign currency exchange rates;

and complex foreign laws, treaties including tax laws and the United States Foreign Corrupt Practices Act of 1977. These risks could restrict our ability to operate our international businesses profitably and therefore have a negative impact on our

financial position and results of operations. In addition, our reported results of operations and financial position could also be negatively affected by exchange rates when the activities and balances of our foreign operations are translated into

U.S. dollars for financial reporting purposes.

The accounting treatment of equity method investments, goodwill and other long-lived assets

could result in future asset impairments, which would reduce our earnings.

We periodically test our equity method

investments, goodwill and other long-lived assets to determine whether their estimated fair value is less than their value recorded on our balance sheet. The results of this testing for potential impairment may be adversely affected by the

continuing uncertain market conditions for the steel industry, as well as changes in interest rates and general economic conditions. If we determine that the fair value of any of these assets is less than the value recorded on our balance sheet, and

in the case of equity method investments the decline is other than temporary, we would likely incur a non-cash impairment loss that would negatively impact our results of operations.

12

Tax increases and changes in tax rules could adversely affect our financial results.

The steel industry and our business are sensitive to changes in taxes. As a company based in the U.S., Nucor is more exposed to the

effects of changes in U.S. tax laws than some of our major competitors. Our provision for income taxes and cash tax liability in the future could be adversely affected by changes in U.S. tax laws. Potential changes that would adversely affect us

include, but are not limited to, current proposals for corporate tax reform which would lower tax rates and eliminate most tax deductions [repealing LIFO (last-in, first-out treatment of inventory), accelerated depreciation, and the domestic

production activity deduction] and decrease the ability of U.S. companies to receive a tax credit for foreign taxes paid or to defer the U.S. deduction of expenses in connection with investments made in other countries.

We are subject to legal proceedings and legal compliance risks.

We spend substantial resources ensuring that we comply with domestic and foreign regulations, contractual obligations and other legal standards. Notwithstanding this, we are subject to a variety of

legal proceedings and compliance risks in respect of various issues, including regulatory, safety, environmental, employment, transportation, intellectual property, contractual, import/export, international trade and governmental matters that arise

in the course of our business and in our industry. For information regarding our current significant legal proceedings, see Item 3. “Legal Proceedings.” A negative outcome in an unusual or significant legal proceeding or compliance

investigation could adversely affect our financial condition and results of operations. While we believe that we have adopted appropriate risk management and compliance programs, the nature of our operations means that legal and compliance risks

will continue to exist and additional legal proceedings and other contingencies, the outcome of which cannot be predicted with certainty, will arise from time to time.

| Item 1B. |

Unresolved Staff Comments |

None.

13

We own all of

our principal operating facilities. These facilities, by segment, are as follows:

|

|

|

|

|

|

|

| Location |

|

Approximate

square footage

of facilities |

|

|

Principal products |

| Steel mills: |

|

|

|

|

|

|

| Blytheville, Arkansas |

|

|

2,560,000 |

|

|

Steel shapes, flat-rolled steel |

| Berkeley County, South Carolina |

|

|

2,180,000 |

|

|

Flat-rolled steel, steel shapes |

| Decatur, Alabama |

|

|

2,000,000 |

|

|

Flat-rolled steel |

| Crawfordsville, Indiana |

|

|

1,900,000 |

|

|

Flat-rolled steel |

| Norfolk, Nebraska |

|

|

1,480,000 |

|

|

Steel shapes |

| Hickman, Arkansas |

|

|

1,450,000 |

|

|

Flat-rolled steel |

| Hertford County, North Carolina |

|

|

1,220,000 |

|

|

Steel plate |

| Plymouth, Utah |

|

|

1,200,000 |

|

|

Steel shapes |

| Jewett, Texas |

|

|

1,080,000 |

|

|

Steel shapes |

| Darlington, South Carolina |

|

|

980,000 |

|

|

Steel shapes |

| Seattle, Washington |

|

|

640,000 |

|

|

Steel shapes |

| Memphis, Tennessee |

|

|

570,000 |

|

|

Steel shapes |

| Ghent, Kentucky |

|

|

560,000 |

|

|

Flat-rolled steel |

| Auburn, New York |

|

|

450,000 |

|

|

Steel shapes |

| Marion, Ohio |

|

|

440,000 |

|

|

Steel shapes |

| Kankakee, Illinois |

|

|

430,000 |

|

|

Steel shapes |

| Jackson, Mississippi |

|

|

420,000 |

|

|

Steel shapes |

| Kingman, Arizona |

|

|

380,000 |

|

|

Steel shapes |

| Tuscaloosa, Alabama |

|

|

370,000 |

|

|

Steel plate |

| Birmingham, Alabama |

|

|

280,000 |

|

|

Steel shapes |

| Wallingford, Connecticut |

|

|

260,000 |

|

|

Steel shapes |

|

|

|

| Steel products: |

|

|

|

|

|

|

| Norfolk, Nebraska |

|

|

1,080,000 |

|

|

Joists, deck, cold finished bar |

| Brigham City, Utah |

|

|

730,000 |

|

|

Joists, cold finished bar |

| Grapeland, Texas |

|

|

680,000 |

|

|

Joists, deck |

| St. Joe, Indiana |

|

|

550,000 |

|

|

Joists, deck |

| Chemung, New York |

|

|

550,000 |

|

|

Joists, deck |

| Florence, South Carolina |

|

|

540,000 |

|

|

Joists, deck |

| St. Joe, Indiana |

|

|

530,000 |

|

|

Fasteners |

| Fort Payne, Alabama |

|

|

470,000 |

|

|

Joists, deck |

The steel mills segment also includes Skyline, our steel foundation distributor with U.S. manufacturing

facilities in eight states and one facility in Canada, the majority of which are owned. Additionally, we have a distribution center in Pompano Beach, Florida and in Mexico.

In the steel products segment, we have 79 additional operating facilities in 36 states and 28 operating facilities in Canada. Our affiliate, Harris Steel Inc., also operates multiple sales offices in

Canada and certain other foreign locations.

In the raw materials segment, DJJ has 78 operating facilities in 16 states along

with multiple brokerage offices in the U.S. and certain other foreign locations. Nucor’s raw materials segment also includes our DRI facilities. Nucor has DRI facilities in Point Lisas, Trinidad and St. James Parish, Louisiana. A significant

portion of the DRI production process occurs outdoors. The Trinidad site, including leased land, is approximately 1.84 million square feet. The Louisiana site, which began operations in December 2013, has approximately 174.2 million square

feet of owned land with buildings that total approximately 72,000 square feet.

14

During 2014, the average utilization rates of all operating facilities in the steel mills,

steel products and raw materials segments were approximately 78%, 64% and 63% of production capacity, respectively.

We also

own our principal executive office in Charlotte, North Carolina.

| Item 3. |

Legal Proceedings |

Nucor

has been named, along with other major steel producers, as a co-defendant in several related antitrust class-action complaints filed by Standard Iron Works and other steel purchasers in the United States District Court for the Northern District of

Illinois. The majority of these complaints were filed in September and October of 2008, with two additional complaints being filed in July and December of 2010. Two of these complaints have been voluntarily dismissed and are no longer pending. The

plaintiffs allege that from April 1, 2005 through December 31, 2007, eight steel manufacturers, including Nucor, engaged in anticompetitive activities with respect to the production and sale of steel. The plaintiffs seek monetary and other

relief. Five of the eight defendants have reached court approved settlements with the plaintiffs. Although we believe the plaintiffs’ claims are without merit and will vigorously defend against them, we cannot at this time predict the outcome

of this litigation or estimate the range of Nucor’s potential exposure. Nucor has not recorded any reserves or contingencies related to this legal matter.

On April 19, 2012, MM Steel LP filed an action against Nucor and its co-defendants in the U.S. District Court for the Southern District of Texas and has asserted violations of federal antitrust law.

On March 25, 2014, the jury returned a verdict of $52.0 million in damages against all defendants jointly and severally, which amount was subject to trebling under the federal antitrust laws. On June 1, 2014, the court awarded a judgment

jointly and severally against the defendants totaling $160.8 million after trebling and including costs and attorneys’ fees. Although the Company has filed an appeal with the U.S. Court of Appeals for the Fifth Circuit and believes that it has

valid grounds to have the judgment vacated or reversed, the ultimate resolution of the case is uncertain. Nucor has not recorded any reserves or contingencies related to this legal matter.

Nucor is from time to time a party to various lawsuits, claims, and other legal proceedings that arise in the ordinary course of

business. With respect to all such lawsuits, claims and proceedings, we record reserves when it is probable a liability has been incurred and the amount of loss can be reasonably estimated. We do not believe that any of these proceedings,

individually or in the aggregate, would be expected to have a material adverse effect on our results of operations, financial position or cash flows. Nucor maintains liability insurance for certain risks that is subject to certain self-insurance

limits.

| Item 4. |

Mine Safety Disclosures |

Not applicable.

Executive Officers of the Registrant

James R. Darsey (59), Executive Vice President of Merchant and Rebar

Products, was named EVP in September 2010. Prior to that, he served as President of the Vulcraft/Verco Group from 2007 and was elected Vice President of Nucor in 1996. He began his Nucor career in 1979 as Design Engineer at Vulcraft-Texas, later

serving as Engineering Manager at Vulcraft-Utah and Vulcraft-Texas. He then served as General Manager of Vulcraft-Texas and General Manager of Nucor Steel-Texas.

John J. Ferriola (62) has served as Chairman of the Board of Directors of Nucor since January 2014, as Chief Executive Officer since January 2013 and as President since January 2011.

Previously, Mr. Ferriola served as President and Chief Operating Officer from January 2011 to December 2012 and, prior to that, as Chief Operating Officer of Steelmaking Operations from 2007 to 2010, Executive Vice President from 2002 to 2007

and Vice President from 1996 to 2001. He has also been a director of Nucor since January 2011. Mr. Ferriola joined Nucor in 1991 as the Manager of Maintenance and Engineering at Nucor Steel-Texas. He later served as General Manager of

Vulcraft-Texas, Nucor Steel-Nebraska and Nucor Steel-Indiana.

15

James D. Frias (58) has been Chief Financial Officer, Treasurer and Executive

Vice President since January 2010. Prior to that, Mr. Frias was Vice President of Finance from 2006 to 2009. Mr. Frias joined Nucor in 1991 as Controller of Nucor Building Systems-Indiana. He also served as Controller of Nucor

Steel-Indiana and as Corporate Controller. Mr. Frias joined the board of directors of Carlisle Companies Incorporated in February 2015.

Ladd R. Hall (58), Executive Vice President of Flat-Rolled Products, was named EVP in September 2007, having previously served as Vice President of Nucor since 1994. He began his Nucor career in

Inside Sales at Nucor Steel-Utah in 1981. He later served as Sales Manager of Vulcraft-Utah, and General Manager of Vulcraft-Texas, Vulcraft-Utah, Nucor Steel-South Carolina and Nucor Steel-Berkeley County.

Raymond S. Napolitan, Jr. (57) was named Executive Vice President of Fabricated Construction Products in June 2013, having

previously served as President of Nucor’s Vulcraft/Verco group from 2010 to 2013 and President of American Buildings Company from 2007 to 2010. He was elected Vice President of Nucor in 2007. He began his Nucor career in 1996 as Engineering

Manager of Nucor Building Systems-Indiana, and later served as General Manager of Nucor Building Systems-Texas.

R. Joseph

Stratman (58), Executive Vice President of Raw Materials, was named EVP in September 2007, having previously served as Vice President of Nucor since 1999. He joined Nucor in 1989 as Controller of Nucor Building Systems-Indiana. He then served as

Controller of Nucor-Yamato Steel Company, General Manager of Nucor Steel-Nebraska and General Manager of Nucor-Yamato Steel Company.

David A. Sumoski (48) was named Executive Vice President of Engineered Bar Products in September 2014. He had previously served as General Manager of Nucor Steel Marion, Inc. from 2008 to 2012

and as General Manager of Nucor Steel Memphis, Inc. from 2012 to September 2014. He was named Vice President of Nucor in 2010. He began his career with Nucor as an electrical supervisor at Nucor Steel-Berkeley in 1995, later serving as Maintenance

Manager.

D. Chad Utermark (46) was named Executive Vice President of Beam and Plate Products in May 2014. He had

previously served as General Manager of Nucor Steel-Texas from 2008 to 2011 and as General Manager of Nucor-Yamato Steel Company from 2011 to May 2014. He was named Vice President of Nucor in 2009. He began his Nucor career as a utility operator at

Nucor Steel-Arkansas in 1992, subsequently serving as shift supervisor and Hot Mill Manager at that division as well as Roll Mill Manager at Nucor Steel-Texas.

16

PART II

| Item 5. |

Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities |

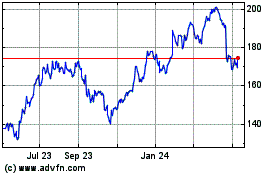

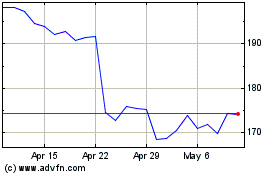

Nucor has increased its base cash dividend every year since the Company began paying dividends in 1973. Nucor paid a

total dividend of $1.48 per share in 2014 compared with $1.47 per share in 2013. In December 2014, the board of directors increased the base quarterly cash dividend on Nucor’s common stock to $0.3725 per share from $0.37 per share. In February

2015, the board of directors declared Nucor’s 168th

consecutive quarterly cash dividend of $0.3725 per share payable on May 11, 2015 to stockholders of record on March 31, 2015.

Additional information regarding the market for Nucor’s common stock, quarterly market price ranges, the number of stockholders and dividend payments is incorporated by reference to Nucor’s 2014

Annual Report, page 78. Additional information regarding securities authorized for issuance under stock-based compensation plans is incorporated by reference to Nucor’s 2014 Annual Report, pages 63 through 66.

| Item 6. |

Selected Financial Data |

Historical financial information is incorporated by reference to Nucor’s 2014 Annual Report, page 43.

| Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

Information required by this item is incorporated by reference to Nucor’s 2014 Annual Report, page 3 (Forward-looking Statements) and

pages 22 through 39.

| Item 7A. |

Quantitative and Qualitative Disclosures About Market Risk |

In the ordinary course of business, Nucor is exposed to a variety of market risks. We continually monitor these risks and develop strategies to manage them.

Interest Rate Risk—Nucor manages interest rate risk by using a combination of variable-rate and fixed-rate debt. At

December 31, 2014, 23% of Nucor’s long-term debt was in industrial revenue bonds that have variable interest rates that are adjusted weekly. The remaining 77% of Nucor’s long-term debt was at fixed rates. Future changes in interest

rates are not expected to significantly impact earnings. Nucor also occasionally makes use of interest rate swaps to manage net exposure to interest rate changes. As of December 31, 2014, there were no such contracts outstanding. Nucor’s

investment practice is to invest in securities that are highly liquid with short maturities. As a result, we do not expect changes in interest rates to have a significant impact on the value of our investment securities recorded as short-term

investments.

Commodity Price Risk—In the ordinary course of business, Nucor is exposed to market risk for price

fluctuations of raw materials and energy, principally scrap steel, other ferrous and nonferrous metals, alloys and natural gas. We attempt to negotiate the best prices for our raw materials and energy requirements and to obtain prices for our steel

products that match market price movements in response to supply and demand. In periods of strong or stable demand for our products, we are more likely to be able to effectively reduce the normal time lag in passing through higher raw material costs

so that we can maintain our gross margins. When demand for our products is weaker, this becomes more challenging.

Natural gas

produced by Nucor’s working interest drilling programs is being sold to third parties to offset our exposure to changes in the price of natural gas consumed by our Louisiana DRI facility. In addition to the future natural gas needs at the

Louisiana DRI facility that began operations in the fourth quarter of 2013, Nucor is also a substantial consumer of natural gas at our steel mill operations. Natural gas produced through the working interest drilling programs is expected to be

sufficient in the future to cover Nucor’s demand at all of its steel mills in the United States plus the demand of two DRI plants or, alternatively, at three DRI plants. However,

17

the natural gas production from the working interest drilling programs currently does not completely cover the natural gas usage at our operating facilities due to the temporary cessation of

drilling discussed below. For the year ended December 31, 2014, the volume of natural gas sold from our natural gas working interest drilling programs was approximately 66% of the volume of natural gas purchased for consumption in our domestic

steelmaking and DRI facilities.

Our natural gas working interest drilling programs are affected by changes in natural gas

prices in an inverse manner to natural gas costs at our DRI and steel mill operations. As natural gas prices increase, our increased energy costs at our DRI and steel mill operations is somewhat mitigated by increased profit from sales of natural

gas to third party customers from our natural gas drilling programs. Likewise, as natural gas prices decrease, we experience decreased energy costs at our DRI and steel mill operations, but we also experience decreased profit from our natural gas

drilling programs.

The impact of low natural gas prices associated with our drilling programs is limited by the existence of

a drilling suspension clause. Nucor is contractually obligated to drill a minimum number of wells per year under the terms of our original agreements with Encana; however, we have the right to suspend drilling of new wells if market pricing falls

below a pre-established threshold. In the fourth quarter of 2013, we announced a joint decision with Encana to temporarily suspend drilling new natural gas wells until there is a sustained improvement in natural gas pricing. In the fourth quarter of

2014 Nucor and Encana agreed to further suspend drilling through calendar year 2015, except for a de minimis number of wells that are necessary in order to retain leasehold rights. We believe that this pause demonstrates the flexibility of our

partnership with Encana to react to market conditions to the mutual benefit of both parties while still allowing us to better manage our exposure to natural gas pricing volatility at our operating divisions that consume natural gas.