Southwest Incident Linked to Cracked Engine Blade

September 12 2016 - 6:20PM

Dow Jones News

The U.S. aviation-safety watchdog on Monday linked a cracked

jet-engine fan blade to the emergency landing of a Southwest

Airlines Co. plane last month, as part of its preliminary

investigation to identify the cause of the unusual incident.

The National Transportation Safety Board has yet to conclude the

root cause of what happened but said it found cracking consistent

with metal fatigue on a remaining piece of one of the engine's

broken fan blades. The engine was made by General Electric Co.'s

joint venture CFM International with France's Safran SA.

None of the 99 passengers or five crew aboard were injured

during the flight from New Orleans to Orlando, Fla., which was

forced to land in Pensacola, Fla., on Aug. 27 after the rare engine

failure, which caused major engine damage and led to

depressurization of the cabin.

The failure of a fan blade is a rare event, and engines are

designed to contain them inside the engine casing or to eject any

debris safely out of the back. The failure aboard the Southwest jet

was characterized as uncontained by the NTSB, meaning debris was

ejected out of the sides of the engine, an extremely unusual

event.

The failure of one of the engine's 38 front fan blades appeared

to precede the significant damage sustained by the CFM engine

nacelle, according to an industry official, followed by the

complete separation of the forward inlet. The NTSB said debris from

the inlet damaged the Boeing Co. 737-700 jet's fuselage, wing and

tail stabilizers.

The CFM56-7 series engine involved in the accident was one of

the oldest in service, according to the official. However, the age

of an engine and its internal components aren't necessarily related

as parts are refurbished or replaced during the life of an

engine.

An NTSB spokesman said the agency's investigation is ongoing and

a sequence of events wasn't included in its preliminary findings. A

Southwest Airlines spokesman said repairs to the jet have begun and

the company continues "to work closely with the NTSB on the

investigation of this unique and extremely rare event."

Aircraft and their engines are subjected to repeated stresses

during their life in service and cracks are a normal part of their

aging, but if left unchecked, they can cause major damage to an

aircraft. Regulators, airlines and manufacturers have developed

inspection regimes to identify and remedy cracks before they become

safety issues.

The source of the cracking on the titanium alloy blade was still

under investigation, and the NTSB said it was continuing to review

the engine's maintenance records and test the remaining blades.

CFM is the biggest engine manufacturer in the world for

single-aisle aircraft, such as the workhorse Boeing 737.

Write to Jon Ostrower at jon.ostrower@wsj.com

(END) Dow Jones Newswires

September 12, 2016 18:05 ET (22:05 GMT)

Copyright (c) 2016 Dow Jones & Company, Inc.

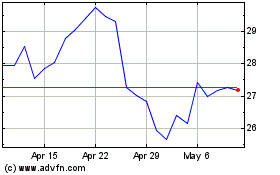

Southwest Airlines (NYSE:LUV)

Historical Stock Chart

From Mar 2024 to Apr 2024

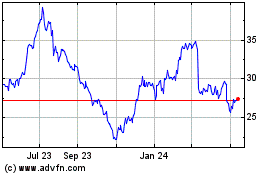

Southwest Airlines (NYSE:LUV)

Historical Stock Chart

From Apr 2023 to Apr 2024