UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

Juniper Networks, Inc.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| Delaware |

|

001-34501 |

|

77-0422528 |

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

|

|

|

| 1133 Innovation Way,

Sunnyvale, California |

|

94089 |

| (Address of principal executive offices) |

|

(Zip Code) |

Mitchell Gaynor (408) 745-2000

(Name and telephone number, including area code, of the

person to contact in connection with this report.)

Check the appropriate box to

indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

With respect to the reporting period from January 1, 2014 to December 31, 2014, Juniper Networks, Inc. (the “Company”) has determined that

(i) tin, tantalum, tungsten, and gold, which are “conflict minerals” as defined in Section 1, Item 1.01(d)(3) of Form SD, are necessary to the functionality or production of products that the Company has manufactured or

contracted to manufacture, and (ii) based upon a reasonable country of origin inquiry, the Company has reason to believe that a portion of its necessary conflict minerals originated or may have originated in the Democratic Republic of the Congo

or an adjoining country (as defined in Section 1, Item 1.01(d)(1) of Form SD) and has reason to believe that those necessary conflict minerals may not be from recycled or scrap sources.

Conflict Minerals Disclosure

In accordance with Rule

13p-1 promulgated under the Securities Exchange Act of 1934, as amended (“Rule 13p-1”), and this Specialized Disclosure Report on Form SD (this “Form”), the Company has filed a Conflict Minerals Report, which is attached as

Exhibit 1.01. A copy of this Form and the Conflict Minerals Report are publicly available at http://investor.juniper.net/investor-relations/sec-filings/default.aspx.

In accordance with Rule 13p-1, and this Form, the Company has filed a Conflict Minerals Report,

which is attached as Exhibit 1.01.

Section 2 – Exhibits

|

|

|

| Exhibit

No. |

|

Description |

|

|

| Exhibit 1.01 |

|

Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form. |

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by

the duly authorized undersigned.

|

|

|

|

|

| Juniper Networks, Inc. |

|

|

|

| By: |

|

/s/ Mitchell L. Gaynor |

|

Date: May 29, 2015 |

| Name: |

|

Mitchell L. Gaynor |

|

|

| Title: |

|

Executive Vice President and General

Counsel |

|

|

EXHIBIT INDEX

|

|

|

| Exhibit

No. |

|

Description |

|

|

| Exhibit 1.01 |

|

Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form. |

Exhibit 1.01

Juniper Networks, Inc.

Conflict Minerals Report For The Year Ended December 31, 2014

This Conflict Minerals Report (this “Report”) for Juniper Networks, Inc. (the “Company”, “Juniper”, “our” or

“we”) covers the reporting period from January 1, 2014 to December 31, 2014, and is presented in accordance with Rule 13p-1 promulgated under the Securities Exchange Act of 1934, as amended (“Rule 13p-1”).

This Report is filed as Exhibit 1.01 to the Company’s Specialized Disclosure Report on Form SD (the “Form”), and a copy of this Report and the

Form are publicly available at http://investor.juniper.net/investor-relations/sec-filings/default.aspx.

This Report, including the section

entitled “Future Steps”, contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 regarding our business, products and conflict minerals compliance efforts, including steps we intend to

take to mitigate the risk that conflict minerals in our products benefit armed groups, and the industry’s conflict minerals efforts. Words such as “expects,” “anticipates,” “targets,” “goals,”

“projects,” “would,” “could,” “intends,” “plans,” “believes,” “seeks,” “estimates,” variations of such words, and similar expressions are intended to identify such

forward-looking statements. Forward-looking statements by their nature address matters that are, to different degrees, uncertain, and these forward-looking statements are only predictions and are subject to risks, uncertainties, and assumptions that

are difficult to predict. While forward-looking statements in this Report are based on reasonable expectations of our management at the time that they are made, you should not rely on them. Forward-looking statements are inherently subject to risks

and uncertainties and actual results and outcomes may differ materially from the results and outcomes discussed in or anticipated by the forward-looking statements. Factors that could cause or contribute to such differences in results and outcomes

include, without limitation, the risk that information reported to us by our direct suppliers or industry information used by us may be inaccurate; the risk that smelters or refiners (processing facilities) may not participate in the Conflict-Free

Smelter Program (the “CFSP”); political and regulatory developments, whether in the Democratic Republic of the Congo and adjoining countries (collectively, the “Covered Countries”), the United States or elsewhere; as well as

risks discussed under the heading “Risk Factors” in our most recent Quarterly Report on Form 10-Q and in other reports we file with the U.S. Securities and Exchange Commission (the “SEC”). Readers are urged not to place undue

reliance on these forward-looking statements, which speak only as of the date of this Report. We undertake no obligation to revise or update any forward-looking statements in order to reflect any event or circumstance that may arise after the date

of this Report.

Throughout this Report, whenever a reference is made to any document, third party material or website (including Juniper’s website),

such reference does not incorporate information from such document, material or website into this Report, unless expressly incorporated by reference herein.

Introduction

This Report, which is an exhibit to the

Form, describes the design of Juniper’s conflict minerals due diligence measures, provides an account of how these measures were implemented for 2014 and indicates certain steps we have taken and are anticipated to take in 2015 to mitigate the

risk that necessary conflict minerals in our products benefit armed groups in the Covered Countries. A description of our products covered by this Report is provided under “Part 2: Product Description” of this Report below. For purposes of

this Report, the term “conflict minerals” means columbite-tantalite (coltan), cassiterite, gold, wolframite, and their derivatives tantalum, tin, and tungsten, without regard to their location of origin, and the terms “armed

group” and “DRC conflict free” have the meanings contained in the Form.

Part 1: Due Diligence

Reasonable Country of Origin Inquiry Process

In

accordance with Rule 13p-1 and the Form, Juniper determined that tantalum, tin, tungsten, and gold are necessary to the functionality or production of our products, and are incorporated into our products during the manufacturing process.

Accordingly, Juniper was required to undertake a “reasonable country of origin inquiry” (“RCOI”) with respect to conflict minerals that is reasonably designed to determine whether any of the conflict minerals originated in the

Covered Countries. In designing our RCOI, Juniper employed a combination of measures, as described in this Report, to determine whether the conflict minerals in Juniper’s products originated from the Covered Countries. For its RCOI, to the

extent applicable, Juniper utilized the same processes and procedures as for its due diligence.

In connection with its RCOI, the Company surveyed its

suppliers that provide physical components that become part of our end products or provide manufacturing services for our end products (“direct suppliers”) that represented an aggregate of 96% of total direct expenditures by the Company in

fiscal year 2013, on a consolidated basis, and including 100% of all suppliers that provide manufacturing services for our end products.

Juniper’s suppliers identified 201 known smelters and refiners that may be in its supply chain. Based on

Juniper’s reasonable country of origin inquiry, we concluded that many of these smelters and refiners sourced conflict minerals entirely from outside of the Covered Countries, including from recycled or scrap sources. Juniper’s conclusions

concerning mineral origin are based on information provided by the Conflict-Free Sourcing Initiative (the “CFSI”) to its members.

For 2014,

Juniper was unable to determine the origin of at least a portion of the necessary Conflict Minerals in each of its in-scope products. None of the necessary Conflict Minerals contained in its in-scope products were determined by Juniper to directly

or indirectly finance or benefit armed groups in a Covered Country. However, Juniper did not conclude that any of its in-scope products were “DRC conflict free.”

Based on the results of our RCOI, we are required to conduct due diligence for 2014. These due diligence efforts are discussed below.

Due Diligence Process

Since 2011, Juniper has been a

member of the Electronics Industry Citizenship Coalition (“EICC) – Global eSustainability Initiative (“GeSI”) Extractives Work Group to support the development of industry tools and programs that provide a common means to report

or collect due diligence information on the source and chain of custody of conflict minerals. Since that time, the Extractives Work Group has evolved into the Conflict-Free Sourcing Initiative (“CFSI”), a recognized industry coalition

focused on addressing conflict minerals in the supply chain. Through the CFSI, Juniper has been actively engaged, and continues to work, with industry peers in an effort to ensure that implementation of our due diligence process is aligned with and

complementary to the industry approach. The primary objective of this alignment is to maximize the efficiency and effectiveness of our efforts to identify smelters and refiners in our supply chain and to encourage their participation in the

CFSI’s Conflict-Free Smelter Program (“CFSP”). The CFSP is a voluntary initiative in which an independent third party audits smelter procurement and processing activities and determines if the smelter has provided sufficient

documentation to demonstrate with reasonable confidence that the minerals it processed originated from conflict-free sources. As it is a standardized protocol, we, along with other leading participants in the electronics industry, rely on the CFSP

or equivalent industry-wide program for audits of smelters and/or refiners.

In addition, we conducted due diligence on our supply chain with respect to

the conflict minerals in a manner that conforms, in all relevant material respects given our position in the supply chain, to the five-step Organisation for Economic Co-operation and Development (“OECD”) Due Diligence Guidance for

Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, including the supplements thereto (Second Edition 2013) (collectively, the “Framework”), as it pertains to downstream companies. The Framework is an

internationally recognized due diligence framework.

In accordance with the five-step Framework, the design of Juniper’s due diligence includes, but

is not limited to, the following five steps: (i) establishment of strong company management systems, (ii) identification and assessment of risks in the supply chain, (iii) designing and implementing a strategy to respond to identified

risks, (iv) carrying out independent third-party audit of supply chain due diligence at identified points in the supply chain and (v) reporting on supply chain due diligence. A description of certain activities undertaken by Juniper in

respect of each of the five steps of the Framework is described below. The headings below conform to the headings used in the Framework for each of the five steps. The data on which we relied for certain statements in this declaration was obtained

through our membership in the CFSI, using the Reasonable Country of Origin Inquiry report for member JNPR.

| 1. |

Establishment of Strong Company Management Systems |

Juniper has established a management system for

addressing the sourcing of conflict minerals in our products. The elements of our management system include:

| |

a. |

Adopt and Commit to a Supply Chain Policy for Conflict Minerals: Juniper has a company policy that explains the importance of the conflict minerals issue and our responsibility for addressing conflict minerals in

our supply chain. A copy of Juniper’s Supply Chain policy for Conflict Minerals can be viewed at http://www.juniper.net/us/en/company/citizenship-sustainability/supply-chain/#conflict-minerals. |

| |

b. |

Internal Management to Support Supply Chain Due Diligence: Juniper has a conflict minerals governance structure that includes executive champions and an operations team comprised of individuals from Worldwide

Operations; Environmental, Health, Safety and Security; Engineering; Investor Relations; Finance; Internal Audit; Sales; and Legal. Our conflict minerals operations team, under the leadership and purview of Juniper’s executive champions, guides

the continued development and implementation and maintenance of Juniper’s conflict minerals program. Executive champions establish the goals of the conflict minerals operations team, receive report-outs on the status of the program, provide the

necessary signature to this Form, and evaluate whether Juniper should suspend, disengage or take other action with respect to a supplier. |

| |

c. |

Controls and Transparency: Juniper undertook a RCOI with respect to conflict minerals in its supply chain and determined to prioritize direct suppliers based, in part, on their aggregate expenditures in the prior

fiscal year. For 2014, Juniper selected and surveyed direct suppliers representing approximately 96% of Juniper’s fiscal year 2013 consolidated direct expenditures (including 100% of all suppliers that provide manufacturing services for our end

products). In order to develop a system of transparency and controls over conflict minerals in our supply chain, Juniper provided the Conflict Minerals Reporting Template (the “CMRT”) designed by the CFSI to all such suppliers in order to

gather information about their use of conflict minerals, their mineral sourcing practices and the smelters and refiners in their supply chain. We elected to use the CMRT as we believe that it is a commonly used reporting template used in numerous

industries, thereby easing the potential for confusion or misunderstanding by our suppliers and helping to foster even more widespread adoption of the CMRT. In furtherance of our survey of such suppliers, Juniper engaged a third-party resource to

provide assistance in the collection, verification and retention of information about conflict minerals in our supply chain. |

| |

d. |

Supplier Engagement: Juniper continues to actively work to strengthen our relationship with our suppliers, and in the course of the collection of the CMRT, Juniper directly engaged with a number of our suppliers

to provide information about the conflict minerals rule and their role in assisting Juniper to comply. We also made available training and access to resources through our third-party resource to assist our suppliers to complete their respective

CMRTs. In addition, Juniper encourages all suppliers of materials, products, software, and/or services to adhere to a Supplier Code of Conduct. A copy of our Supplier Code of Conduct can be viewed at

http://www.juniper.net/assets/us/en/local/pdf/flyer/9040062-en.pdf. The Supplier Code of Conduct sets expectations for ethical conduct on a range of business practices, including conflict minerals, and is integrated into direct supplier

agreements. Annually, Juniper verifies that the top spend direct suppliers’ comply with the Supplier Code of Conduct through desk audits. Additionally, Juniper conducts onsite audits of some key direct suppliers, including 100% of

Juniper’s manufacturing suppliers. Juniper shares observations and recommendations from these audits with the direct suppliers and, where appropriate, works with direct suppliers to implement corrective actions. The results from these supplier

audits are inputs to the supplier scorecard, which is reviewed at least annually with the direct supplier. |

| |

e. |

Grievance Mechanism: Juniper’s worldwide Reporting Ethics Concerns Policy and hotline accepts and encourages reporting of illegal or unethical activity for internal and external stakeholders to report known,

suspected false or other information concerning conflict minerals. This process is also outlined in our Supplier Code of Conduct and can be viewed at http://www.juniper.net/us/en/company/citizenship-sustainability/ethics-compliance/.

|

| 2. |

Identification and Assessment of Risks in the Supply Chain |

Given our position in the supply chain, such

that we do not have any direct relationship with the smelters or refiners in our supply chain, we relied heavily on our first-tier in-scope suppliers to provide information about the sources of conflict minerals used in our products. We accomplished

this analysis by providing our surveyed suppliers with the CMRT, and we, either directly or through our third-party resource, provided assistance to our in-scope suppliers in understanding and completing the CMRT. Upon receipt of responses to our

CMRT request, Juniper and our third-party resource follow up with in-scope suppliers that do not respond to the request within the specified time frame. The information is requested from each in-scope supplier multiple times to the extent the

in-scope supplier continues to be non-responsive. After multiple requests, if a response is not received from an in-scope supplier, the request is escalated to the applicable buying group within the Company for additional follow up.

Juniper and our third-party resource review the responses received from in-scope suppliers. The third-party resource reviews the responses received from

in-scope suppliers for plausibility, consistency and gaps, and will follow up with suppliers that submit a response that triggers specified quality control flags.

This process included comparing smelter names provided by the in-scope supplier to those set forth on publicly available CFSI smelter lists and the list of

smelters and refiners published by the U.S. Department of Commerce to determine whether the entities are in fact smelters or refiners, and, if so, whether they are compliant with the CFSP.

| 3. |

Designing and Implementing a Strategy to Respond to Identified Risks |

Juniper has developed and

implemented a strategy to respond to identified risks of conflict minerals in the supply chain.

After assessing the data provided by our suppliers, a

summary of identified risk factors and risk mitigation steps, if any, is prepared for the executive champions at Juniper. Based on the data collected, the main risks that we have identified are suppliers providing incomplete, illogical, or

inconsistent responses in the CMRT; an incomplete list of smelter names; the names of smelters or refiners being provided that are not on the list of recognized smelters published by the CFSI or the U.S. Department of Commerce; or smelters

that are not certified by the CFSP. We seek to mitigate these risks by taking the steps described in Items 1 and 2 above. In addition, in connection with Juniper’s efforts to support the

CFSI and to assist in the creation of a more comprehensive list of known smelters and refiners, Juniper sends the list of entities that are not on the CFSI’s list, which may or may not be actual smelters or refiners, to the CFSI for its

analysis and possible inclusion in a future CFSI list of known smelters and refiners. As of the date of this Report, we have not identified a supplier, smelter or refiner that we have reason to believe is sourcing conflict minerals from a Covered

Country and that is, directly or indirectly, financing or benefiting armed groups. However, we have not determined that any of our products are “DRC conflict free.”

| 3. |

Carrying Out Independent Third-Party Audit of Supply Chain Due Diligence at Identified Points in the Supply Chain |

Juniper does not have a direct relationship with any smelters or refiners in our supply chain and, as a result, Juniper does not directly conduct audits of

smelters or refiners. Instead, Juniper participates with industry peers, as a member of the CFSI, which, among other activities, sponsors and facilitates the CFSP, which conducts a conflict free certification program for smelters and refiners

through third party audits. Juniper supports the CFSI financially through our membership dues and has joined the CFSI’s Smelter Engagement Team (“SET”) in 2015 to support the goal of increased smelter and refiner participation in the

audit program by reaching out to specific smelters and refiners to directly encourage their participation. Juniper also provides the SET with information about its smelter list to contribute to the industry’s awareness of the known smelter

universe. Based on our 2014 survey of in-scope suppliers, Juniper provided the names of 128 alleged smelters, as reported by our suppliers, to the SET. In addition, Juniper refers to the list of CFSP compliant smelters and refiners when evaluating

our supplier responses related to smelters and refiners in our supply chain with respect to the risk assessment and mitigation steps described above.

| 4. |

Reporting on Supply Chain Due Diligence |

We publicly filed the Form and this Report with the SEC, and a

copy of this Report and the Form are publicly available on our website at http://investor.juniper.net/investor-relations/sec-filings/default.aspx.

Future Steps

Juniper takes seriously the allegations

that trade of conflict minerals sourced from the Covered Countries may fund violent conflicts in that region.

For 2015, we intend to continue to focus

our efforts on collaborating with industry peers through our membership in the CFSI to improve the systems of transparency and control in our supply chain, including through our use of new Revision 4.0 of the CMRT in connection with our diligence of

our supply chain. In addition, Juniper intends to, as a member of the SET, conduct outreach to specific smelters and refiners to directly encourage their participation in the CFSP. Juniper also intends to (i) continue our engagement with our

relevant first-tier suppliers in order to further build their knowledge and capacity so they are able to provide more complete and accurate information on the source and chain of custody of conflict minerals in our supply chain and

(ii) continue our work with a third-party resource to refine the process for conducting follow-up with our surveyed direct suppliers to more effectively resolve unreasonable or illogical responses in their surveys. All of these steps are in

addition to the steps that Juniper took in respect of 2014, which we intend to continue to take in respect of 2015 to the extent applicable.

Part

2: Product Description

Smelters and Refiners in Juniper’s Supply Chain

Based on our reasonable country of origin inquiry and due diligence, as applicable, the names of known smelters and refiners of conflict minerals that may be

in our supply chain are listed below, including whether such smelters or refiners participate in the CFSP and their compliance status. The below list does not contain the names of entities received as responses to the CMRTs submitted by our

suppliers that, as of April 14, 2015 were not listed on the CFSI’s list of known smelters and refiners or the Commerce Department list.

A

summary of the known smelters and refiners for each conflict mineral that may be in our supply chain and whether such smelters and refiners are CFSP compliant or otherwise in process with the CFSP is provided below:

| |

• |

|

75% (69/92) of known Gold smelters or refiners that may be in our supply chain are CFSP compliant, active in the CFSP, or in communication with the CFSP. |

| |

• |

|

100% (24/24) of known Tantalum smelters or refiners that may be in our supply chain are CFSP compliant or active in the CFSP. |

| |

• |

|

72% (46/64) of known Tin smelters or refiners that may be in our supply chain are CFSP compliant, active in the CFSP, or in communication with the CFSP |

| |

• |

|

100% (20/20) of known Tungsten smelters or refiners that may be in our supply chain are CFSP compliant, active in the CFSP, in communication with the CFSP, or members of the Tungsten Industry Conflict Minerals

Council (“TI-CMC”) that have committed to complete a CFSP validation audit within two years. |

Not all of the included smelters and refiners may have processed the necessary conflict minerals contained in

Juniper’s in-scope products, since some suppliers reported at a “company level,” meaning that they reported the conflict minerals contained in all of their products, not just those in the products that they sold to Juniper. Some

suppliers also may have reported smelters and refiners that were not in Juniper’s supply chain due to over-inclusiveness in the information received from their suppliers or for other reasons. In addition, the smelters and refiners reflected

below likely does not include all of the smelters and refiners in Juniper’s supply chain, since some suppliers did not identify any smelters or refiners and because not all suppliers responded to Juniper’s inquiries.

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| Gold |

|

|

|

|

| Allgemeine Gold-und

Silberscheideanstalt A.G. |

|

|

C |

|

| AngloGold Ashanti Córrego do Sítio

Mineração |

|

|

C |

|

| Argor-Heraeus SA |

|

|

C |

|

| Asahi Pretec Corporation |

|

|

C |

|

| Atasay Kuyumculuk Sanayi Ve Ticaret A.S. |

|

|

C |

|

| Aurubis AG |

|

|

C |

|

| Boliden AB |

|

|

C |

|

| CCR Refinery – Glencore Canada

Corporation |

|

|

C |

|

| Chimet S.p.A. |

|

|

C |

|

| Dowa |

|

|

C |

|

| Eco-System Recycling Co., Ltd. |

|

|

C |

|

| Heimerle + Meule GmbH |

|

|

C |

|

| Heraeus Ltd. Hong Kong |

|

|

C |

|

| Heraeus Precious Metals GmbH & Co. KG |

|

|

C |

|

| Ishifuku Metal Industry Co., Ltd. |

|

|

C |

|

| Istanbul Gold Refinery |

|

|

C |

|

| Japan Mint |

|

|

C |

|

| Johnson Matthey Inc |

|

|

C |

|

| Johnson Matthey Ltd |

|

|

C |

|

| JSC Ekaterinburg Non-Ferrous Metal

Processing Plant |

|

|

C |

|

| JX Nippon Mining & Metals Co., Ltd. |

|

|

C |

|

| Kazzinc Ltd |

|

|

C |

|

| Kennecott Utah Copper LLC |

|

|

C |

|

| Kojima Chemicals Co., Ltd |

|

|

C |

|

| L’ azurde Company For Jewelry |

|

|

C |

|

| LS-NIKKO Copper Inc. |

|

|

C |

|

| Materion |

|

|

C |

|

| Matsuda Sangyo Co., Ltd. |

|

|

C |

|

| Metalor Technologies (Hong Kong) Ltd |

|

|

C |

|

| Metalor Technologies (Singapore) Pte. Ltd. |

|

|

C |

|

| Metalor Technologies SA |

|

|

C |

|

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| Metalor USA Refining Corporation |

|

|

C |

|

| METALÚRGICA MET-MEX PEÑOLES,

S.A. DE C.V |

|

|

C |

|

| Mitsubishi Materials Corporation |

|

|

C |

|

| Mitsui Mining and Smelting Co., Ltd. |

|

|

C |

|

| Nadir Metal Rafineri San. Ve Tic. AŞ |

|

|

C |

|

| Nihon Material Co. LTD |

|

|

C |

|

| Ohio Precious Metals, LLC |

|

|

C |

|

| OJSC “The Gulidov Krasnoyarsk Non-

Ferrous Metals Plant” |

|

|

C |

|

| PAMP SA |

|

|

C |

|

| PT Aneka Tambang (Persero) Tbk |

|

|

C |

|

| PX Précinox SA |

|

|

C |

|

| Rand Refinery (Pty) Ltd |

|

|

C |

|

| Royal Canadian Mint |

|

|

C |

|

| Schone Edelmetaal |

|

|

C |

|

| SEMPSA Joyería Platería SA |

|

|

C |

|

| Shandong Zhaojin Gold & Silver Refinery

Co. Ltd |

|

|

C |

|

| Solar Applied Materials Technology Corp. |

|

|

C |

|

| Sumitomo Metal Mining Co., Ltd. |

|

|

C |

|

| Tanaka Kikinzoku Kogyo K.K. |

|

|

C |

|

| Umicore Brasil Ltda |

|

|

C |

|

| Umicore SA Business Unit Precious Metals

Refining |

|

|

C |

|

| United Precious Metal Refining, Inc. |

|

|

C |

|

| Valcambi SA |

|

|

C |

|

| Western Australian Mint trading as The

Perth Mint |

|

|

C |

|

| Chugai Mining |

|

|

|

|

| Do Sung Corporation |

|

|

|

|

| Hwasung CJ Co. Ltd |

|

|

|

|

| Korea Metal Co. Ltd |

|

|

|

|

| Samduck Precious Metals |

|

|

|

|

| SAMWON METALS Corp. |

|

|

|

|

| Torecom |

|

|

|

|

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| Aida Chemical Industries Co. Ltd. |

|

|

A |

|

| Asaka Riken Co Ltd |

|

|

A |

|

| Cendres + Métaux SA |

|

|

A |

|

| Sabin Metal Corp. |

|

|

A |

|

| SOE Shyolkovsky Factory of Secondary Precious

Metals |

|

|

A |

|

| YAMAMOTO PRECIOUS METAL CO., LTD. |

|

|

A |

|

| Yokohama Metal Co Ltd |

|

|

A |

|

| Almalyk Mining and Metallurgical Complex (AMMC) |

|

|

|

|

| Bangko Sentral ng Pilipinas (Central Bank of the

Philippines) |

|

|

|

|

| Bauer Walser AG |

|

|

|

|

| Caridad |

|

|

|

|

| Daejin Indus Co. Ltd |

|

|

|

|

| Daye Non-Ferrous Metals Mining Ltd. |

|

|

|

|

| FSE Novosibirsk Refinery |

|

|

|

|

| Guangdong Jinding Gold Limited |

|

|

|

|

| Inner Mongolia Qiankun Gold and Silver Refinery

Share Company Limited |

|

|

|

|

| Jiangxi Copper Company Limited |

|

|

|

|

| JSC Uralelectromed |

|

|

|

|

| Kyrgyzaltyn JSC |

|

|

|

|

| Lingbao Jinyuan Tonghui Refinery Co. Ltd. |

|

|

|

|

| Moscow Special Alloys Processing Plant |

|

|

|

|

| Navoi Mining and Metallurgical Combinat |

|

|

|

|

| OJSC Kolyma Refinery |

|

|

|

|

| Prioksky Plant of Non-Ferrous Metals |

|

|

|

|

| So Accurate Group, Inc. |

|

|

|

|

| The Great Wall Gold and Silver Refinery of China |

|

|

|

|

| Tongling nonferrous Metals Group Co., Ltd |

|

|

|

|

| Yunnan Copper Industry Co Ltd |

|

|

|

|

| Zhongyuan Gold Smelter of Zhongjin Gold

Corporation |

|

|

|

|

| Zijin Mining Group Co. Ltd |

|

|

|

|

| Tantalum |

|

|

|

|

| Changsha South Tantalum Niobium Co., Ltd. |

|

|

C |

|

| Conghua Tantalum and Niobium Smeltry |

|

|

C |

|

| Duoluoshan |

|

|

C |

|

| Exotech Inc. |

|

|

C |

|

| F&X Electro-Materials Ltd. |

|

|

C |

|

| H.C. Starck Co., Ltd. |

|

|

C |

|

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| H.C. Starck Inc. |

|

|

C |

|

| H.C. Starck Ltd. |

|

|

C |

|

| H.C. Starck Smelting GmbH & Co.KG |

|

|

C |

|

| Hi-Temp Specialty Metals, Inc. |

|

|

C |

|

| JiuJiang JinXin Nonferrous Metals Co., Ltd. |

|

|

C |

|

| Jiujiang Tanbre Co., Ltd. |

|

|

C |

|

| KEMET Blue Metals |

|

|

C |

|

| KEMET Blue Powder |

|

|

C |

|

| Metallurgical Products India (Pvt.) Ltd. |

|

|

C |

|

| Mitsui Mining & Smelting |

|

|

C |

|

| Ningxia Orient Tantalum Industry Co., Ltd. |

|

|

C |

|

| RFH Tantalum Smeltry Co., Ltd |

|

|

C |

|

| Solikamsk Magnesium Works OAO |

|

|

C |

|

| Taki Chemicals |

|

|

C |

|

| Telex |

|

|

C |

|

| Ulba |

|

|

C |

|

| Zhuzhou Cement Carbide |

|

|

C |

|

| King-Tan Tantalum Industry Ltd |

|

|

A |

|

| Tin |

|

|

|

|

| Alpha |

|

|

C |

|

| CV United Smelting |

|

|

C |

|

| Dowa |

|

|

C |

|

| Gejiu Non-Ferrous Metal Processing Co. Ltd. |

|

|

C |

|

| Magnu’s Minerais Metais e Ligas LTDA |

|

|

C |

|

| Malaysia Smelting Corporation (MSC) |

|

|

C |

|

| Mineração Taboca S.A. |

|

|

C |

|

| Minsur |

|

|

C |

|

| Mitsubishi Materials Corporation |

|

|

C |

|

| OMSA |

|

|

C |

|

| PT Babel Inti Perkasa |

|

|

C |

|

| PT Bangka Putra Karya |

|

|

C |

|

| PT Bangka Tin Industry |

|

|

C |

|

| PT Bukit Timah |

|

|

C |

|

| PT DS Jaya Abadi |

|

|

C |

|

| PT Eunindo Usaha Mandiri |

|

|

C |

|

| PT REFINED BANGKA TIN |

|

|

C |

|

| PT Sariwiguna Binasentosa |

|

|

C |

|

| PT Stanindo Inti Perkasa |

|

|

C |

|

| PT Tambang Timah |

|

|

C |

|

| PT Timah (Persero), Tbk |

|

|

C |

|

| Thaisarco |

|

|

C |

|

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| White Solder Metalurgia e Mineração Ltda. |

|

|

C |

|

| Yunnan Tin Company, Ltd. |

|

|

C |

|

| CNMC (Guangxi) PGMA Co. Ltd. |

|

|

|

|

| China Tin Group Co., Ltd. |

|

|

A |

|

| Cooper Santa |

|

|

A |

|

| CV Gita Pesona |

|

|

A |

|

| CV Nurjanah |

|

|

A |

|

| CV Serumpun Sebalai |

|

|

A |

|

| Fenix Metals |

|

|

A |

|

| Metallo Chimique |

|

|

A |

|

| O.M. Manufacturing (Thailand) Co., Ltd. |

|

|

A |

|

| O.M. Manufacturing Philippines, Inc. |

|

|

A |

|

| PT Artha Cipta Langgeng |

|

|

A |

|

| PT Belitung Industri Sejahtera |

|

|

A |

|

| PT BilliTin Makmur Lestari |

|

|

A |

|

| PT Karimun Mining |

|

|

A |

|

| PT Mitra Stania Prima |

|

|

A |

|

| PT Panca Mega Persada |

|

|

A |

|

| PT Prima Timah Utama |

|

|

A |

|

| PT Sumber Jaya Indah |

|

|

A |

|

| PT Tinindo Inter Nusa |

|

|

A |

|

| Rui Da Hung |

|

|

A |

|

| Soft Metais, Ltda. |

|

|

A |

|

| Yunnan Chengfeng Non-ferrous Metals Co., Ltd. |

|

|

A |

|

| CV Makmur Jaya |

|

|

|

|

| Estanho de Rondônia S.A. |

|

|

|

|

| Gejiu Kai Meng Industry and Trade LLC |

|

|

|

|

| Gejiu Zi-Li |

|

|

|

|

| Huichang Jinshunda Tin Co. Ltd |

|

|

|

|

| Linwu Xianggui Smelter Co |

|

|

|

|

| Novosibirsk Integrated Tin Works |

|

|

|

|

| PT Alam Lestari Kencana |

|

|

|

|

|

|

|

|

|

| Standard Smelter Name |

|

CFSP* |

|

| PT Babel Surya Alam Lestari |

|

|

|

|

| PT Bangka Kudai Tin |

|

|

|

|

| PT Bangka Timah Utama Sejahtera |

|

|

|

|

| PT Fang Di MulTindo |

|

|

|

|

| PT HP Metals Indonesia |

|

|

|

|

| PT Koba Tin |

|

|

|

|

| PT Pelat Timah Nusantara Tbk |

|

|

|

|

| PT Seirama Tin investment |

|

|

|

|

| PT Tommy Utama |

|

|

|

|

| PT Yinchendo Mining Industry |

|

|

|

|

| Tungsten |

|

|

|

|

| Ganzhou Huaxing Tungsten Products Co., Ltd. |

|

|

C |

|

| Global Tungsten & Powders Corp. |

|

|

C |

|

| Hunan Chunchang Nonferrous Metals Co., Ltd. |

|

|

C |

|

| Japan New Metals Co., Ltd. |

|

|

C |

|

| Xiamen Tungsten (H.C.) Co., Ltd. |

|

|

C |

|

| Xiamen Tungsten Co., Ltd. |

|

|

C |

|

| A.L.M.T. TUNGSTEN Corp. |

|

|

A |

|

| Tejing (Vietnam) Tungsten Co., Ltd. |

|

|

A |

|

| Wolfram Company CJSC |

|

|

A |

|

| Chongyi Zhangyuan Tungsten Co., Ltd. |

|

|

A |

|

| Fujian Jinxin Tungsten Co., Ltd. |

|

|

A |

|

| Ganzhou Non-ferrous Metals Smelting Co., Ltd. |

|

|

A |

|

| Guangdong Xianglu Tungsten Co., Ltd. |

|

|

A |

|

| Vietnam Youngsun Tungsten Industry Co., Ltd |

|

|

A |

|

| Wolfram Bergbau und Hütten AG |

|

|

A |

|

| Dayu Weiliang Tungsten Co., Ltd. |

|

|

C |

|

| H.C. Starck GmbH |

|

|

C |

|

| Hunan Chenzhou Mining Group Co., Ltd. |

|

|

C |

|

| Kennametal Fallon |

|

|

C |

|

| Kennametal Huntsville |

|

|

C |

|

| * |

This column indicates, as of April 14, 2015, whether the known smelter or refiner participates in the CFSP. For purposes of this table, “C” denotes that the smelter or refiner participates in and has been

listed as “compliant” by the CFSP and “A” denotes that the smelter or refiner is “active” in the CFSP process by agreeing to participate in the CFSP, but that the audit process has not yet been completed. For Tungsten

smelters or refiners, the “A” category also captures TI-CMC members that have committed to complete a CFSP validation audit within two years of TI-CMC membership issuance. Smelter or refiner status reflected in the table is based solely on

information made publicly available by CFSI without independent verification by Juniper. |

DRC Conflict Undeterminable

At Juniper Networks, we design, develop, and sell products and services for high-performance networks to enable customers to build highly scalable, reliable,

secure and cost-effective networks for their businesses, while achieving agility, efficiency and value through automation. We focus on customers and partners across our key market verticals who view these network attributes as fundamental to their

business; including Telecom, Cable Providers, Cloud Providers, National Government, Financial Services, and Strategic Verticals.

For 2014, we conducted

the reasonable country of origin inquiry and due diligence process described above. Based on the foregoing, Juniper was unable to determine the origin of at least a portion of the conflict minerals in each of its in-scope products. Accordingly, we

are identifying that all routing, switching and security hardware products described above have been determined by Juniper to be “DRC conflict undeterminable” (as defined in Section 1, Item 1.01(d)(5) of the Form).

Country of Origin Information and Efforts to Determine Mine Location

The identified countries of origin of the conflict minerals processed by the compliant smelters and refiners listed in the table above may have included the

countries in the categories listed below. The listed countries of origin are derived from information made available by the CFSI to its members. Except for the DRC, the CFSI does not indicate individual countries of origin of the conflict minerals

processed by compliant smelters and refiners. Instead, the CFSI indicates country of origin by category.

L1 – Countries that are not identified as

conflict regions or plausible areas of smuggling or export of materials containing Conflict Minerals out of these regions: Argentina, Australia, Austria, Belgium, Brazil, Chile, China, Colombia, Cote d’Ivoire, Czech Republic, Djibouti, Egypt,

Estonia, Ethiopia, France, Germany, Guyana, India, Indonesia, Ireland, Israel, Japan, Lao People’s Democratic Republic, Luxembourg, Madagascar, Malaysia, Mongolia, Myanmar, Netherlands, Nigeria, Peru, Plurinational State of Bolivia, Portugal,

Republic of Korea, Russian Federation, Sierra Leone, Singapore, Suriname, Switzerland, Thailand, United Kingdom, United States and Zimbabwe.

L2 –

Countries that are known or plausible countries for smuggling, export out of region or transit of materials containing Conflict Minerals: Kenya, Mozambique and South Africa.

L3 – The DRC and its nine adjoining countries: Angola, Burundi, Central African Republic, Republic of Congo, Rwanda, South Sudan, Uganda, United Republic

of Tanzania and Zambia.

DRC – The Democratic Republic of the Congo.

Alternatively, or in addition, some of the compliant smelters and refiners did source or may have sourced from recycled or scrap sources.

Because the CFSI generally does not indicate individual countries of origin of the conflict minerals processed by compliant smelters and refiners, Juniper was

not able to determine the countries of origin of the conflict minerals processed by the listed compliant smelters and refiners with greater specificity. In addition, for some of the listed compliant smelters and refiners, origin information is not

disclosed by the CFSI. Juniper did not determine the countries of origin of the conflict minerals processed by other smelters and refiners listed in the table.

Juniper endeavored to determine the mine or location of origin of the necessary conflict minerals contained in its in-scope products by conducting a

supply-chain survey with suppliers using the CMRT and through the information made available by the CFSI to its members.

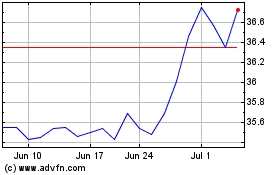

Juniper Networks (NYSE:JNPR)

Historical Stock Chart

From Mar 2024 to Apr 2024

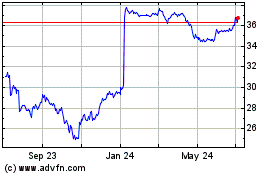

Juniper Networks (NYSE:JNPR)

Historical Stock Chart

From Apr 2023 to Apr 2024