UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

Lockheed

Martin Corporation

|

|

|

|

|

| Maryland |

|

1-11437 |

|

52-1893632 |

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

|

|

|

| 6801 Rockledge Drive, Bethesda, Maryland |

|

20817 |

| (Address of principal executive offices) |

|

(Zip Code) |

Brian P. Colan, Vice President and Controller

(301) 897-6000

(Name and

telephone number, including area code, of the person to contact in connection with this report)

Check the appropriate box to

indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 - Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

A copy of Lockheed Martin

Corporation’s Conflict Minerals Report is provided as Exhibit 1.01 hereto and is publicly available at

http://www.lockheedmartin.com/content/dam/lockheed/data/corporate/documents/Sustainability/conflict-minerals-cmr-2014.pdf.

Item 1.02 Exhibit

As specified in Section 2,

Item 2.01 of this Form SD, the Company is hereby filing its Conflict Minerals Report as Exhibit 1.01 to this Form SD.

Section 2 - Exhibits

Item 2.01 Exhibits

Exhibit 1.01 –

Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

|

|

|

|

|

|

|

|

|

|

Lockheed Martin Corporation |

|

|

|

|

(Registrant) |

|

|

|

|

| Date: May 26, 2015 |

|

|

|

By: |

|

/s/ Brian P. Colan |

|

|

|

|

|

|

Brian P. Colan |

|

|

|

|

|

|

Vice President and Controller |

Exhibit 1.01

Lockheed Martin Corporation

Conflict Minerals Report

For the Year Ended December 31, 2014

Introduction

This Conflict Minerals Report (the

“Report”) has been prepared by Lockheed Martin Corporation (hereinafter referred to as the “Company,” “we,” “us,” or “our”) pursuant to Rule 13p-1 (the “Rule”) promulgated under the

Securities Exchange Act of 1934, as amended. The term “Conflict Minerals” is defined in the Rule and refers to gold and columbite-tantalite (coltan), cassiterite, wolframite, or their derivatives, which are limited to tantalum, tin, and

tungsten (the “Conflict Minerals” or “3TG”). The Rule requires disclosure of certain information when a company manufactures or contracts to manufacture products containing Conflict Minerals that are necessary to the

functionality or production of those products if the company has reason to believe that the Conflict Minerals may have originated in the Democratic Republic of the Congo and the adjoining countries of Angola, Burundi, the Central African Republic,

the Republic of the Congo, Rwanda, South Sudan, Tanzania, Uganda and Zambia (the “Covered Countries”).

Company and Product Overview

We are a global security and aerospace company principally engaged in the research, design, development, manufacture, integration and sustainment of advanced

technology systems, products and services. We also provide a broad range of management, engineering, technical, scientific, logistics, and information services. We operate in five business segments: Aeronautics, Information Systems & Global

Solutions (IS&GS), Missiles and Fire Control (MFC), Mission Systems and Training (MST), and Space Systems. We organize our business segments based on the nature of the products and services offered:

| |

• |

|

Aeronautics is engaged in the research, design, development, manufacture, integration, sustainment, support and upgrade of advanced military aircraft, including combat and air mobility aircraft, unmanned air vehicles,

and related technologies. |

| |

• |

|

IS&GS provides advanced technology systems and expertise, integrated information technology solutions, and management services across a broad spectrum of applications for civil, defense, intelligence, and other

government customers; supports the needs of customers in data analytics, cyber security, air traffic management, and energy demand management; provides network-enabled situational awareness, delivers communications and command and control capability

through complex mission solutions for defense applications, and integrates complex global systems to help our customers gather, analyze, and securely distribute critical intelligence data; and is responsible for various classified systems and

services in support of vital national security systems. |

| |

• |

|

MFC provides air and missile defense systems; tactical missiles and air-to-ground precision strike weapon systems; logistics and other technical services; fire control systems; mission operations support, readiness,

engineering support, and integration services; and manned and unmanned ground vehicles. |

| |

• |

|

MST provides ship and submarine mission and combat systems; mission systems and sensors for rotary and fixed-wing aircraft; sea and land-based missile defense systems; radar systems; the Littoral Combat Ship (LCS);

simulation and training services; and unmanned systems and technologies. |

| |

• |

|

Space Systems is engaged in the research and development, design, engineering, and production of satellites, strategic and defensive missile systems, space transportation systems, and various classified systems and

services in support of vital national security systems. |

1

Covered Products

We conducted an analysis on the products that we manufacture or contract to be manufactured and found that 3TG are in substantially all of our products (and

generally are required for their functionality or production as specified under the Rule) included in the Company and Product Overview. These products are collectively referred to in this Report as the “Covered Products.” 3TG is not

included in the services we provide to our customers.

Supply Chain Description

Our business depends on an extensive global network of suppliers to provide the materials, parts and services to make our final products. As a downstream

company, generally there are multiple tiers between us and our suppliers and the source of raw materials that enter the manufacturing process. The composition of our supply chain makes it challenging to identify the origin of 3TG used in our

products. Therefore, we must rely on our direct suppliers to work with their upstream suppliers to provide us with accurate information (e.g., through the reasonable country of origin inquiry described below) about the origin of 3TG in the materials

and parts that we purchase.

Reasonable Country of Origin Inquiry (“RCOI”)

The elements of our RCOI were: (i) identification of relevant suppliers, (ii) data collection and (iii) assessment of data to determine whether

further due diligence is required.

In 2014, we had direct orders with more than 16,000 active suppliers from more than 50 countries. Because of the

complexity and size of our supply chain, we developed a risk-based approach that focused on our major direct suppliers identified as manufacturers (the “Supplier Group”). The Supplier Group represented more than 90% of our direct material

spending in the previous year.

We collected information from the Supplier Group using the template developed by the Electronics Industry Citizenship

Coalition (EICC) / Global e-Sustainment Initiative (GeSI) (the “EICC Template”). The EICC Template includes questions regarding a direct supplier’s conflict-free policy, its due diligence process, and information about its supply

chain such as the names and locations of smelters and refiners and the origin of 3TG used by those facilities. During 2014, we introduced a web-based survey tool to expedite supplier input and our management of the large number of survey responses.

Based on the RCOI, we do not have sufficient information from the Supplier Group to determine the source of the necessary 3TG contained in our products.

Accordingly, we conducted due diligence on the source and chain of custody of 3TG in our products.

Design of Conflict Minerals Program

As required by the Rule, we conducted due diligence on the source and chain of custody of the necessary 3TG contained in the Covered Products. Our due

diligence program has been designed to conform, in all material respects, with the internationally recognized framework presented by The Organisation for Economic Co-operation and Development (OECD) in the publication OECD (2013) Due

Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas: Second Edition, OECD Publishing (OECD Guidance) and the related supplements for 3TG.

2

Description of Due Diligence Steps Performed

The due diligence steps we performed are set forth below according to the five-step framework established by the OECD:

Step 1: Establish Strong Company Management Systems

| |

• |

|

We have adopted a Conflict Minerals policy statement related to our commitment to responsible sourcing of materials for our products and our establishment of a compliance plan that is designed to follow the OECD

framework. This statement is available on our website. |

| |

• |

|

We have in place a management structure to support supply chain due diligence related to Conflict Minerals. This includes: (1) an executive steering committee led by our controller and global supply chain

executive, which are responsible for our due diligence strategy and our filings and reports under the Rule; (2) a supply chain council, comprised of supply chain leaders from our five business segments, which provide oversight and guidance with

our due diligence by distributing the EICC Template to the Supplier Group and requesting any necessary follow up information; and (3) a multidisciplinary conflict minerals working group comprised of subject matter experts, including

representatives from engineering, finance, legal, sustainability, contracts, communications and our five business segments, which identify the suppliers to be included in the Supplier Group and review supplier responses. |

| |

• |

|

We participate with other manufacturers in the Aerospace and Defense sector in the following industry-wide groups and initiatives: co-leader of the Aerospace Industries Association (AIA) Conflict Minerals Working Group

(CMWG), the National Association of Manufacturers (NAM) Conflict Minerals Implementation Task Force, and the EICC/GeSI Conflict-Free Sourcing Initiative (CFSI). |

| |

• |

|

We are following our established records retention policy that requires us to maintain records related to SEC filings such as the Conflict Minerals reporting for a specified number of years. |

| |

• |

|

We communicate to suppliers our expectations on responsible sourcing of materials through our Supplier Code of Conduct and during 2014 we incorporated the Supplier Code of Conduct in new purchase orders. We maintain a

Suppliers page on our website that includes the Supplier Code of Conduct and other information. |

| |

• |

|

We have an ethics helpline and dedicated ethics and conflict minerals e-mail addresses that provide employees and suppliers with a mechanism to report violations of our Conflict Minerals compliance program or other

concerns. This information is available on our website. Our ethics helpline was also included in our annual ethics letter to suppliers. |

| |

• |

|

We brief senior management about the Company’s practices with respect to 3TG due diligence and supply chain. |

Step 2: Identify and Assess Risks in the Supply Chain

| |

• |

|

We support the EICC and GeSI’s CFSI, an industry initiative that audits smelters’ and refiners’ due diligence activities. As a downstream company, we rely on these initiatives to conduct risk assessment

at the upstream level. |

| |

• |

|

With respect to our direct suppliers, we reviewed the responses we received to the EICC Template that we distributed to the Supplier Group in order to gather information about our supply chain. |

| |

• |

|

Under our due diligence procedures, unresponsive suppliers were issued follow-up requests. Unresponsive suppliers were categorized accordingly in our records. Survey responses were evaluated against pre-determined

criteria, and additional follow-up inquiries were conducted as necessary. Our process allows for escalation of issues to the conflict minerals working group, the supply chain council, and/or the executive steering committee. |

| |

• |

|

During 2014, we attempted mapping of the upstream sources of 3TG in a specific component in one of our products (an electronics assembly) to aid in the development of a process methodology for tracing of conflict

minerals in our products as our conflict minerals program matures. |

3

Step 3: Design and Implement a Strategy to Respond to Identified Risks

| |

• |

|

We have a risk management plan to address concerns that a supplier may be providing us with products that contain 3TG sourced from the Covered Countries. |

| |

• |

|

If a supplier indicates that it directly or indirectly sources 3TG from the Covered Countries, we request additional information from such supplier. If it is confirmed that a supplier provides products or parts for

Covered Products that contain 3TG sourced from the Covered Countries, our program risk management procedures allow for mitigation steps, including conducting a review with the program managers from the affected business segments to determine

appropriate next steps. |

| |

• |

|

During 2014, we did not identify any instance where it was necessary to implement risk mitigation efforts, temporarily suspend trade or disengage with a member of the Supplier Group. |

Step 4: Carry out Independent Third-Party Audit of Smelter/Refiner’s Due Diligence Practices

| |

• |

|

We do not perform or direct audits of 3TG smelters or refiners. We rely on audits conducted by third parties through our membership in the CFSI and supplier self-disclosures of certification status. |

Step 5: Report Annually on Supply Chain Due Diligence

This Report constitutes our annual report on our Conflict Minerals due diligence, and is available on our website at

http://www.lockheedmartin.com/content/dam/lockheed/data/corporate/documents/Sustainability/conflict-minerals-cmr-2014.pdf and is filed with the SEC.

Results of Our Due Diligence Measures

Description of

facilities used to process 3TG; information on country of origin and efforts to determine mine or location of origin

As previously discussed, we found

that 3TG are in substantially all of our products and requested that the Supplier Group complete the EICC Template to determine the facilities used to process 3TG, the country of origin of the 3TG and the mines or locations of origin of the 3TG in

our supply chain. The vast majority of the Supplier Group who responded to our EICC Template indicated in their response that the information provided was at a company or divisional level and did not include a list of smelters. A minority of

responses listed specific smelters and mines, with such responses collectively identifying over 600 smelters and over 200 mines (and in some cases the location of such mines) from which suppliers sourced 3TG. The CFSI Smelter Information Exchange

has validated more than 250 of these smelters as 3TG smelters, of which approximately 53% were certified conflict-free under the Conflict-Free Smelter Program. The survey data also identified 34 suppliers within the Supplier Group who indicated that

they used smelters or mines from the Covered Countries that were included in their supply chain, but stated that they sourced from multiple smelters and mines, and also did not disclose a full product line that would enable us to tie a specific mine

to one of our Covered Products. Because information was generally provided at a company or divisional level and was not tied to specific Covered Products, we did not have sufficient information to identify the facilities that sourced 3TG included in

our Covered Products, or to identify the country of origin of such 3TG.

4

Steps We Have Taken, or Will Take, Since December 31, 2014 to Mitigate Risk that Conflict Minerals

Benefit Armed Groups

Lockheed Martin supports the objective of preventing armed groups in the Covered Countries from benefitting from the sourcing of

Conflict Minerals from that region. We are committed to responsible sourcing of materials for our products, including the sourcing of Conflict Minerals, and we expect that our suppliers are likewise committed to responsible sourcing. We

expect our suppliers to take steps to determine if their products contain Conflict Minerals and if so, implement supply chain due diligence processes to identify sources of these minerals and support efforts to eradicate the use of Conflict Minerals

which directly or indirectly finance or benefit armed groups in the Covered Countries. Accordingly, we intend to take the following steps to further mitigate the risk that the 3TG in our products finance or benefit armed groups in the Covered

Countries:

| |

• |

|

Continue to reference the Lockheed Martin Supplier Code of Conduct in new purchase orders and direct suppliers to our Conflict Minerals Policy Statement and web page. |

| |

• |

|

Survey suppliers representing greater than 90% of related direct material spending as part of our RCOI process (and communicate to our suppliers our expectations regarding improvement of the completeness of information

provided over time). |

| |

• |

|

Continue to participate in the CFSI and in 2015 contribute to the CFSI audit smelter fund with the goal of providing resources sufficient for two smelter audits and conflict free certifications. |

| |

• |

|

Encourage suppliers to participate in the Conflict-Free Smelter Program developed by the CFSI (and engage with our direct suppliers to encourage them to impose requirements on their upstream suppliers to have programs

to eliminate from their supply chain 3TG from conflict mines and become verified as conflict-free through the Conflict-Free Smelter Program or a similar program). |

5

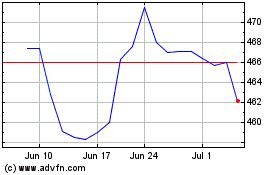

Lockheed Martin (NYSE:LMT)

Historical Stock Chart

From Mar 2024 to Apr 2024

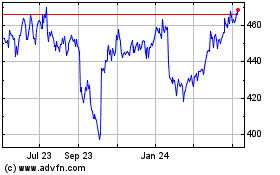

Lockheed Martin (NYSE:LMT)

Historical Stock Chart

From Apr 2023 to Apr 2024