Report of Foreign Issuer (6-k)

November 29 2016 - 4:24PM

Edgar (US Regulatory)

Table of Contents

United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

of the

Securities Exchange Act of 1934

For the month of

November 2016

Vale S.A.

Avenida das Américas, No. 700 — Bloco 8, Sala 218

22640-100 Rio de Janeiro, RJ, Brazil

(Address of principal executive office)

(Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.)

(Check One) Form 20-F

x

Form 40-F

o

(Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1))

(Check One) Yes

o

No

x

(Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7))

(Check One) Yes

o

No

x

(Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.)

(Check One) Yes

o

No

x

(If “Yes” is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b). 82- .)

T

he comeback of a leader

“This presentation may include statements that present Vale's expectations about future events or results. All statements, when based upon expectations about the future and not on historical facts, involve various risks and uncertainties. Vale cannot guarantee that such statements will prove correct. These risks and uncertainties include factors related to the following: (a) the countries where we operate, especially Brazil and Canada; (b) the global economy; (c) the capital markets; (d) the mining and metals prices and their dependence on global industrial production, which is cyclical by nature; and (e) global competition in the markets in which Vale operates. To obtain further information on factors that may lead to results different from those forecast by Vale, please consult the reports Vale files with the U.S. Securities and Exchange Commission (SEC), the Brazilian Comissão de Valores Mobiliários (CVM), the French Autorité des Marchés Financiers (AMF) and in particular the factors discussed under “Forward-Looking Statements” and “Risk Factors” in Vale’s annual report on Form 20-F.” “Cautionary Note to U.S. Investors - The SEC permits mining companies, in their filings with the SEC, to disclose only those mineral deposits that a company can economically and legally extract or produce. We present certain information in this presentation, including ‘measured resources,’ ‘indicated resources,’ ‘inferred resources,’ ‘geologic resources’, which would not be permitted in an SEC filing. These materials are not proven or probable reserves, as defined by the SEC, and we cannot assure you that these materials will be converted into proven or probable reserves, as defined by the SEC. U.S. Investors should consider closely the disclosure in our Annual Report on Form 20-K, which may be obtained from us, from our website or at http://http://us.sec.gov/edgar.shtml.” Disclaimer

Murilo Ferreira Chief Executive Officer

4 Vale’s competitive position stems from four core accomplishments ongoing • Over 300 licenses granted since 2011 allowing timely project implementation • 18 main projects concluded in the last 5 years • Main projects concluded on budget and on time • Over 30% cost reduction since 2012, despite volume increases • Over 80% expenses reduction since 2012 • Focus on core world-class assets • Divestments of almost US$ 13 billion of non-core assets in the last 6 years & Portfolio management P Cost and expenses reduction P Project implementation P Environmental licenses

5 Strategic approach to environmental project implementation licensing allowed timely Main examples • Capão Xavier Expansion • Vargem Grande Itabiritos • Capitão do Mato Expansion Southern System • Abóboras Expansion • Vargem Grande • Fábrica Dam • Maravilhas III Dam Southeastern System • Itabira • Fábrica nova • Brucutu Mine • Brucutu South Dam • Brucutu North Dam Northern System • N5S • N5S Expansion • N4WS • Serra Leste • S11D Mine • S11D Railway • S11D Railway Spur

6 Successful project implementation with disciplined capital allocation allowed reduction in sustaining and growth investments Projects delivered in the last 5 years Capex US$ billion Main examples Sustaining Growth Ferrous minerals Nickel Copper Coal -65% 16.2 2012 2013 2014 2015 2016 Salobo Carajás Additional 40 Conceição Itabiritos Pier IV S11D South Berth Long Harbour Totten Serra Leste Vargem Grande Itabiritos Tubarão VIII Teluk Rubiah Salobo II Conceição Itabiritos II Cauê Itabiritos Nacala Logistics Corridor Moatize II Carajás Serra Sul S11D Railway Spur S11D Pier IV S11D North Berth 2012 2013 2014 2015 2016E • • • • • • • • • • • • • • • • • • 4.6 14.2 4.6 12.0 4.1 8.4 11.6 9.6 2.9 5.6 7.9 5.5 2.4 3.2

7 New mines and infrastructure allowed the achievement of higher ore quality and increased price realization Iron ore sales by type of product Price index % of sales, 9M16 US$/dmt¹ Carajás IOCJ 65% ~40% ~60% Other products (average Fe 62%) 1 Dmt = dry metric ton Carajás IOCJ 65% will represent over 50% of our production by 2020 Date IODEX 62% (A) IOCJ 65% (B) (B-A) 09/15/2016 56.3 64.9 8.6 09/30/2016 55.9 63.6 7.7 10/15/2016 57.5 67.0 9.5 10/30/2016 65.4 75.9 10.5 11/15/2016 73.0 84.5 11.5 11/28/2016 81.6 94.5 12.9

8 Cost discipline led to a material reduction in costs and expenses Costs1 Expenses1,2 US$ billion US$ billion -31% -82% 22.7 6.9 21.2 20.5 17.0 15.7 - 15.8 3 4.5 3.5 4 1.9 1.2 - 1.3 5 5 2012 2013 2014 2015 2016E 2012 2013 2014 2015 2016E 1 Net of depreciation and amortization 2 Includes SG&A, R&D, Pre-operating and stoppage and other expenses; does not include gain/loss on sale of assets 3 Positive impact of US$ 244 million from the goldstream transaction in 1Q13 4 Positive impacts of US$ 230 million from the goldstream transaction in 1Q15 and US$ 331 million of Asset Retirement Obligations (ARO) 5 FX Rate of BRL/USD 3.30 for 2H16 on average; includes the positive impact of US$ 150 million from the goldstream transaction in 3Q16 on expenses

9 Vale optimized its asset base by divesting non-core assets and unlocking US$ billion value Tres Valles Fosbrasil Log-In Belo Monte stake Norsk Hydro CADAM Oil and gas concessions Ferroalloys in Europe 8 VLOCs¹ Goldstream I Araucária Goldstream II El Hatillo 4 VLOCs1 MBR Aluminum assets VLI preferred shares Goldstream III 10 VLOCs¹ 2011 US$ 1.1 billion 2012 US$ 1.5 billion 2013 US$ 6.0 billion 2015 US$ 3.0 billion 2016 US$ 1.1 billion 1 Very Large Ore Carriers Reference US$ 1 billion

10 Net debt will decline in the near dividend payments term while still considering Reaching a sound financial position • Cash generation plus divestments to reduce debt Net debt target of US$ 17 billion New dividend policy in line with cash flow generation Focus on shareholder return • 15-• • Shareholder remuneration Balance sheet strengthening Divestment program Free cash flow generation

Clovis Torres Executive Officer – Human Resources, Sustainability, Compliance and General Counsel

12 Sustainability is one of Vale’s strategic pillars Examples Safety • Annual Safety Reflection Day promoted for all employees and contractors • Zero harm targeted throughout all operations Community • Over 70% of work force locally hired • Local suppliers prioritized, acting as a driver for local development Environment • Energy matrix composed of 25% of renewable energy • Almost 280,000 km² of natural areas preserved Governance • All employees trained on anticorruption in 2016 • Sustainability KPIs considered in all Vale’s employees remuneration

13 Significant progress achieved Examples Health and Safety1 Environment1 Local development2 1 Values for Ferrous Minerals business segment, 2015 vs. 2014 2 Values for Vale • Social and environmental investment: US$ 800 million invested • Favoring local regions: 8% increase in local purchases, totaling 72% • Water resources: 85% of recycling and reuse in the process • Atmospheric emissions: 19% reduction in particulate emissions in pelletizing plants • Safety management: 18% reduction in total injury rate • Risk management: 17% reduction in the number of incidents with high potential impact

14 Zero harm in our operations is our utmost goal Accomplishments Total recordable injuries frequency rate Per million hours worked -45% 3.3 2.8 2.6 2.2 2.1 1.8 1 2011 2012 2013 2014 2015 2016 1 Year to date • Promotion of “Safe Choices” through “Stop, Think, Care” campaign • Reduction of risks through increased control mechanisms, technical improvements and implementation of the Integrated HSE Management System • Recognition for Voisey’s Bay being the mine with the lowest injury frequency rate in Canada (John T. Ryan Award)

15 Success in environmental licensing with more than 300 granted was crucial to timely project implementation Number of licenses granted per year licenses Intense period of project implementation 64 63 54 53 36 35 2011 2012 2013 2014 2015 2016¹ 1 Licenses granted up to October 2016

16 S11D sets projects a benchmark on sustainability applied to large scale S11D long distance conveyor belt electricity savings 18,000 MW of per year 70% less fuel by using 37 km of conveyor belts The world’s leading iron ore project •Low impact •Truckless operation •Dry processing •Low CO2 emissions 86% of reuse of water 93% less water consumption

17 Vale currently generates 51% of its worldwide electricity needs from its own hydro plants which guarantees stable prices through PPAs1 Capim Branco II Hydroelectric Dam 1 Power purchase agreement Guaranteed energy average of 652 MW 100% of energy output sold in long-term through PPAs1 1,158 MW of installed capacity 7 hydro power plants in full operation 55%45%

18 Renova Foundation has been diligently working to remediate and compensate for the damages of the Samarco’s dam failure • The Foundation was created on August 2nd, 2016 with the support of Samarco and its shareholders The Foundation main purpose is to implement and manage the repair, restauration and reconstruction programs of the regions affected by the collapse of the Fundão Dam The scope of actions is focused on environmental and socio-economic recovery programs • •

19 The scope of actions spans from reconstruction of infrastructure to monitoring of water quality Reconstruction work Reconstruction work Water treatment in Governador Valadares New road construction - Paracatú

20 Several reconstruction communities initiatives have taken place in the affected Examples of initiatives November 2015 September 2016 Main road in Barra Longa soon after the dam failure Main road in Barra Longa after clean-up

21 Revegetation has taken place in several river springs Examples of initiatives November 2015 March 2016 Carmo river soon after the dam failure Carmo river after revegetation works

Peter Poppinga Executive Officer, Ferrous Minerals

23 Main accomplishments • Steady development of the S11D project – Delivery of the north berth at Pier IV • Consistent progress on the ramp-up of key projects – N4WS and N5S mine extensions (Northern System) – Itabiritos projects (Conceição, Cauê Itabiritos and Vargem Grande) ect • Substantial gains in productivity throughout the supply chain – Global recovery rate improved from 45% in 9M15 to 48% in 9M16 – Blended volumes¹ increased from 18 Mt in 2015 to 40 Mt in 2016 ctivity • Significant margin improvements – C1² cash costs in BRL reduced by 23% in 3Q16 vs. 4Q14 – Iron ore and pellets cash breakeven3 reduced by 53% in 3Q16 vs. 4Q14 – Price realization improved to 110% of the average Platts IODEX 62% in 1H16 from 103% in 1H15 1 Include Malaysia, Oman and China 2 C1 cash cost at the port (mine, plant, railroad and port) 3 Including sustaining investment Proj implemen progre Produ gain Marg improve tation ss s in ment

24 The hot commission of S11D mine and plant is progressing well with start-up expected in 2016 S11D Mine and Plant - Physical progress of 96% - Ore stocking in the stockyards initiated with over 300,000 tons of ROM

25 The railway spur started up in early October with the circulation of the first train with 330 wagons Railway - Start-up of the railway spur in October - Physical progress of railway duplication at 59% with 289 km of 570 km duplicated

26 The new berth at Pier IV loaded 2 vessels in October and first commercial shipment with S11D ore is expected in January 2017 Port onshore and offshore - 5 vessels loaded up to Nov-16 with a total of 1.3 Mt of ore - Physical progress of 93%

27 The successful ramp-up of projects helped to boost Vale’s results Production volumes – N4WS and N5S mine extension C1 cash cost1 in the Northern System Mt R$/t - 13% Other Northern System mines N4WS and N5S 43.2 37.7 75.1 46.3 9M15 9M16 9M15 9M16 1 C1 cash cost at the port (mine, plant, railroad and port, excluding royalties) 46.7 32.4

28 The ramp-ups together with operational efficiency resulted in the increase of the Global recovery1, % global recovery1 and other productivity gains 48 46 41 39 2013 2014 2015 2016E 1 Global recovery = total production / (waste + ROM)

29 Productivity gains and production increase more than recent appreciation of the Brazilian currency US$/t, 3Q16 vs. 2Q16 offset the Increase of 3 p.p. in global recovery from 2Q16 to 3Q16 Increase in production of 5 Mt in 3Q16 vs. 2Q16 0.3 1.0 0.6 13.2 0.3 13.0 2Q16 C1 cash cost Exchange rate variation Global recovery Fixed cost dilution Productivity gains and other savings 3Q16 C1 cash cost

30 Price realization improved relative to Ratio of price realization to the Platts 62% Fe content1, % peers in 2016 Vale² Peer 1 Peer 2 Peer 3 110% 99% 1H15 1H16 1 On a CFR and dry metric ton basis 2 Includes adjustment for the pellets margin gains Source: Financial reports of Vale and Peers Vale’s higher price realization compared to the Platts 62% Fe content will be enhanced as premiums on high grade increase and, consequently, peers with lower grade ore will be more penalized 107% 101% 103% 102% 83% 91%

31 Closing the previous Cash generation1, US$/t iron ore competitiveness gap Vale² Peer 1 Peer 2 Peer 3 Vale’s 3Q16 27.5 26.4 26.5 1H15 1H16 1 Measured by EBITDA per ton less sustaining investments per ton 2 Adjusted EBITDA of iron ore, pellets, ROM and other ferrous for Vale’s figures Source: Financial reports of Vale and peers 13.3 22.0 11.0 20.420.520.5

32 Vale will deliver on 3 key initiatives competitiveness to further increase its Ramp-up of S11D 1 2 Optimization of global supply chain 3 Improvement of global recovery

33 S11D will C1 cash cost1 further decrease Vale’s costs and sustaining Sustaining capex capex 1 US$/t US$/t 2 3 - 41% - 28% - 29% - 25% 13.0 2.5 2.4 Current Vale² Current Carajás² Expected S11D³ Current Vale² Current Carajás² Expected S11D³ 1 C1 cash cost at the port (mine, plant, railroad and port, excluding royalties) 2 Vale’s Current and Carajás based on 3Q16 3 S11D fully ramped up, normalized to the exchange rate of BRL/USD 3.37 S11D will consolidate Vale’s position as the lowest C1 cash cost producer of the industry Reduction through truckless operation and dry processing 1.8 10.8 7.7

34 Optimization of Vale’s integrated global supply chain – increasing its efficiency through productivity and cost reduction 1 2 3 • Replacement of trucks for belt conveyors in Brucutu, Itabira and Água Limpa (Southeastern System), as well as in N4WS (Northern System) Increase in productivity of port operations in Brazil due to reduction in number of final products and progressive increase of Valemax’s fleet Increase of Valemax full discharge in China and increase of vessels discharging at a single port leading to freight reductions 2nd generation of Valemaxes Integrated management of the freight portfolio1, resulting in further freight reductions Elimination of the floating transfer stations • • • • • 1 Adjusting the volumes of spot chartering and short term Contracts of Affreightement (COAs) according to market conditions

35 price Optimization of Vale’s integrated global supply chain – improving realization 1 Examples 2 Development of new distribution channels Realization of full value in use of high grade ore 3 • Vale’s supply growth is mainly concentrated in the Northern System, with Carajás product characteristics that will enable: - Higher productivity for steel mills - Less usage of coking coal - Less emission during steel making process • Strengthen our ability to capture value gaps in the market through improved management of blending optionalities • Develop the market opportunities for low alumina ore • Increase market capillarity and customer base • Increase offshore blending capacity • Develop the option to sell in RMB • Develop partnerships with local traders and ports

36 Vale has the flexibility to shape Premiums and discounts over the 62% Fe index1 its supply for any market scenario 1 US$/t 2 65% Fe BRBF premium 58% Fe LAPS² 3 15 10 5 0 -5 -10 -15 -20 -25 • Steel mills are progressively seeking for more productivity, thus supporting a structural trend for higher premiums for high grade fines • The optionality of offshore blending enables Vale to explore margin optimization, positively impacting price realization Aug-15 Oct-15 Dec-15 Feb-16 Apr-16 Jun-16 Aug-16 Oct-16 1 Absolute price spread between each index and the 62% Fe MB, average up to November 25th, 2016 2 LAPS = low alumina, phosphorus and sulphur Source: Metal Bulletin 58% Fe

37 Vale is progressively reducing its time to market by moving inventory throughout the supply chain 1 2 Share of offshore over total inventories Offshore blending capacity 3 Mtpy % 80 - 90 35% 2015 2016E 2017E 2015 2016E 2017E The reduction of logistics bottlenecks in Brazil enables the inventory movement downstream Offshore blending capacity will increase by more than 5x in 2017 vs. 2015 25% 10% 40 18

38 Goal of achieving highest global recovery among peers as a result of higher share of dry processing and optimization of strip ratio 1 2 Levers Global recovery1 rate 3 %, 2020 • Strip ratio improvement by grinding and concentrating compact itabirites and by allowing for some flexibility in the alumina and phosphorous contents of intermediate products 54 • Increase of dry processing from 40% in 2016 to 60% in 2020 and 70% in 2022 in conjunction with a revision of mine plans, increasing the life of mines, postponing replacement investments, whilst lowering production costs Vale Peer 1 Peer 2 Peer 3 1 Global recovery = total production / (waste + ROM) Source: Vale, Woodmac and peers reports 383836

39 The review of mine plans will reduce future expenditures while maintaining Fe content, % the highest average product quality in the industry • • - Real 66.5 ---2015 Plan 66.0 - New projection 65.5 65.0 ,, ,, ------_ ,,'' 64.5 64.0 63.5 63.0 +---....-----.------.------.-------.-------.------.-------.------.------.------.-------.------,------, 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021

40 The new mine plan is based on the simplification of the portfolio with final products being formed closer to customers 1 2 Before 3 product After products virtual blend 1 Distribution center The offshore blending allows Vale to ship intermediate products from Brazil, thus eliminating the need for each system to produce a final saleable product Mine (natural moisture route) MineCrushingScreeningIntermediate Customers Final products formed closer to customers in DC’s1, Chinese ports, or Ports Few products Southern / Southeastern and IOCJ Customers Final products formed in Brazilian ports Mine (wet processing route) MineCrushingScreening Milling ConcentrationTailing dam Saleable Ports Many products

41 Global recovery increase will substantially reduce our replacement capex expenditure needs until 2030 1 2 Number of projects1 to maintain 450 Mtpy from 2017 to 2030 Long term capex1 to maintain 450 Mtpy from 2017 to 2030 3 US$ billion 26 22 2014 2015 2016 2014 2015 2016 Strategic plans Strategic plans 1 Does not include the S11D project, 65% of capex disbursements will happen after 2025. 9 6 11 5

42 Compared to its peers, Vale has a lower depletion rate, thus having the lowest future capital Depletion of Vale vs. its main peers intensity of the industry Chinese domestic production vs. investments 1 2 3 Chinese concentrate production, M wmt Investment (growth %, YoY) 420 360 60% 45% 300 240 180 30% 15% 0% 120 -15% 60 0 -30% -45% 1 Considering production volumes of 2016 2 Absolute estimated capital disbursement to implement the projects Source: Vale internal data and JP Morgan report on August, 2016 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 9M16 • Vale will not have to invest over the next 7 years to maintain its capacity and has enough brownfield options to replace its production • The average incentive price of these replacement projects is around US$ 50/t 5-7 years view Vale Peer 1 Peer 2 Peer 3 Depletion Mt 14 50 80 25 Proportion of production¹ 4% 15% 31% 15% Capex² (US$ billion) 0.3 – 0.4 2.0 – 3.5 1.6 – 3.2 1.0 – 1.5 Type of project Brownfield Greenfield Brownfield Greenfield

43 Vale will maintain production discipline to maximize margins Production volumes¹ range Northern System capacity range Mtpy Mtpy Production range Northern System Previous ramp-up Current ramp-up 400-450 400-450 400-430 400-420 230 230 2016E 2017E 2018E 2019E 2020E 2021E 2016E 2017E 2018E 2019E 2020E 1 Including third party purchases 180 230 218 206 175 153 360-380 340-350 230 230 218 206 175 153

44 Minerals1 EBITDA per ton of Ferrous is expected to increase between US$ 3/t to US$ US$/t, 9M16 vs. 2020 5/t by 2020 0.5 3.0 - 5.0 S11D Optimization of the global supply chain Global recovery Others Total 1 Assuming no change in Platts IODEX 62% reference price, bunker oil prices, and exchange rate of BRL 3.37 / USD 0.5 - 1.0 1.0 - 2.0 1.0 - 1.5

45 Iron ore will be a strong cash generator irrespective of market prices, with its EBITDA potentially 2020 EBITDA1, US$ billion reaching US$ 18 billion in 2020 Platts IODEX (US$/t) 1 Assuming bunker oil prices of US$ 260/t, for every US$ 100/t in bunker oil variation the EBITDA will vary approximately US$ 1 billion Exchange rate BRL/USD 50 60 70 3.2 10.0 13.9 17.8 3.4 10.3 14.2 18.1 3.6 10.5 14.4 18.3

JenniferMaki Executive Officer, Base Metals

47 Main accomplishments • Production of nickel and copper increased by 21% and 24% since 20131 – Production from VNC increased by 140% – Production from Salobo increased by 173% ect up • Productivity gains throughout the supply chain – VNC reduced costs by US$ 110 million compared to 2015 – Salobo reduced costs by US$ 17 million compared to 2015, while increasing production by 14% • Significant cost and expenses decrease since 2013 – Unit costs2 decreased 31% in nickel and 58% in copper – Expenses decreased by 75% ement 1 Increase from 2013 to 2016E 2 After by-products Proj ramp-Supply c optimiza Margi improv hain tion n

48 Ramp-ups Nickel have been progressing well Copper1 kt kt 448 414 315 291 275 260 2013 2014 2015 2016E 2013 2014 2015 2016E basis in October at 17,156t 1 Excluding Lubambe’s attributable production Salobo reaching nominal capacity on a monthly Several operations achieving record production months in the 2H16: (i) VNC at 4,034t, (ii) Long Harbour at 2,054t and (iii) Onça Puma at 2,524t 361369

49 Nickel and copper costs have declined consistently Nickel operations1 after by-products South Atlantic Copper after by-products US$/t US$/t -31% -54% 8,634 8,268 8,312 6,000 4,084 2,826 2,022 1,900 2013 2014 2015 2016E 2013 2014 2015 2016E 1 Includes VNC and Long Harbour

50 Expenses1,2 US$ million decreased 75% since 2013 -75% 1,4143 861 4 773 347 5 2013 2014 2015 2016E 1 2 3 4 5 Net of insurance effects, depreciation and amortization Includes SG&A, R&D, Pre-operating and stoppage and other expenses Excludes the positive one-off impact of US$ 244 million of the goldstream transaction in 1Q13 Excludes the positive one-off impact of US$ 230 million of the goldstream transaction in 1Q15 Excludes the positive one-off impact of US$ 150 million of the goldstream transaction in 3Q16 Source: Company annual and quarterly reports, 2016 estimated

51 We achieved many improvements in 2016, with initiatives to be undertaken in 2017 that will strengthen our competitive position 1 Optimize North Atlantic operations 2 Continue with VNC de-risking plan 3 Develop PTVI’s potential for expansions 4 Consolidate Salobo’s cash generation position

52 Sudbury is transitioning to single furnace operation 1 1Q17 2Q17 3Q17 4Q17 2 3 Commissioning Transition 70% copper as concentrate Clarabelle Mill 4 2 furnaces (#1 old #2 rebuilt) 2 furnaces 1 furnace (rebuild #2) 1 furnace (#2 rebuilt) Furnaces Rebuilt furnace #2 with increase in capacity Copper production through smelter Copper anode to market Copper matte to market 4-week maintenance of surface plants • Shift to single furnace and significant flowsheet change in 2017 while operating - Increase in production of copper concentrate to maximize room in the furnace for nickel - Rebuild of furnace #2 with expanded capacity - Maintenance shutdown in June 2017 (4 weeks) - Cease copper anode production and sell copper matte to market • Permanent direct cost reduction of US$ 42 million in 2018

53 Thompson will shift from an integrated to a mine-mill operation 1 • The transition will start in 1Q17 with the decommission of one of the two furnaces in Thompson 2017 will be the last year for processing Voisey’s Bay feed in Thompson The remaining smelting and refining assets will be closed in 2018 and the operation will focus on nickel concentrate production - Sudbury and Long Harbour refineries will process Thompson concentrate A simpler and leaner structure will be in place in 2018 2 3 4 • • •

54 Long Harbour will ramp up to designed flowsheet in 2017 1 Finished nickel production Unit cash cost of sales after by-product credits 2 Yearly production, t US$/t 3 -58% 4 9,000 50,000 47,000 31,000 5,000 4,000 3,800 16,000 2016E 2017E 2018E 2019E 2016E 2017E 2018E 2019E • Long Harbour will finalize the commissioning of all its circuits in 2017, encompassing: - Start-up of copper and cobalt electrowinning circuits - Processing of midgrade concentrate from Voisey’s Bay - Improvement of nickel purity in our products

55 Vale will continue with VNC de-risking plan 1 2 3 4 • Cost reductions of over US$ 100 million in 2016 - - - US$ 70 million on better management of suppliers contract US$ 15 million on materials and spare parts control US$ 15 million on labor and administration • • EUR 200 million loan from the French government 2017 focus on operational improvements to increase production and further reduce costs

56 VNC will increase production and decrease unit costs 1 Nickel production Unit cash cost of sales after by-product credits 2 t US$/t 3 4 -54% 56,000 21,559 50,000 44,000 43,500 36,000 12,200 Less than 10,000 11,000 11,000 10,300 2016E 2017E 2018E 2019E 2020E 2015 2016E 2017E 2018E 2019E 2020E Note: VNC site cost to nickel oxide sinter

57 Develop PTVI’s potential for expansions 1 2 3 • Expansion of our mining and processing facilities at Sorowako through: 4 - Continuous improvement to support growth with focus on capital discipline Modernization of the furnaces to optimize production and increase cost efficiency Processing capacity by 2019 will increase 8 kt¹ as a result of optimization initiatives - - • Further expansions include: - Optionality of inviting strategic partners in Pomalaa and Bahodopi to exploit the saprolite ore layer - Increase of production via 5th line expansion according to market conditions 1 Compared to 2015 production

58 Salobo is a world-class copper operation and has potential for further expansion 1 2 3 4 • Salobo III represents a low-cost brownfield expansion opportunity * Expansion through the addition of a concentration plant for extra 12 Mtpy processing capacity Leverage on current experience with Salobo’s ore body to increase gold and copper production Project still subject to approval of Board of Directors - - • Synergies with Silver Wheaton to be further explored to reduce the capital expenditures required First deep exploration drilling at Salobo in 2017 to assess potential for an underground mine •

59 Steady Nickel nickel and copper production Copper1 kt kt Sudbury Thompson Voisey's Bay Sorowako Onça Puma VNC Sudbury Thompson Voisey's Bay Salobo Sossego 456 472 470 470 448 315 317 316 308 301 2016E 2017E 2018E 2019E 2020E 2016E 2017E 2018E 2019E 2020E 1 Not including Lubambe

60 Base Metals has growth potential due to strong resources and expansion opportunities if the market conditions are there • Strong reserve position with industry leading resources across our operations • Able to maintain nickel production for next 25 years - well beyond in New Caledonia, Brazil, and Indonesia • World-class copper reserves at Salobo • Further upside potential: - - - Increase in Salobo mineral resources Continued extension and discovery in Sudbury Larger underground resource at Voisey’s Bay

61 Sound EBITDA generation going forward even with moderate increases in nickel and copper prices EBITDA 2018 US$ billion Copper Price (US$/t) Nickel Price (US$/t) • Modest increases in commodity prices produce an amplified impact on our EBITDA generation • EBITDA more sensitive to changes in copper prices after Salobo’s ramp-up 4,500 5,000 5,500 6,000 6,500 7,000 7,500 8,000 0.8 1.0 1.2 1.4 1.6 1.8 2.0 10,000 1.4 1.6 1.8 2.0 2.2 2.4 2.6 12,000 2.0 2.2 2.4 2.6 2.8 3.0 3.2 14,000 2.6 2.8 3.0 3.2 3.4 3.6 3.8 16,000 3.2 3.4 3.6 3.8 4.0 4.2 4.4 18,000 3.8 4.0 4.2 4.4 4.6 4.8 5.0 20,000 4.4 4.6 4.8 5.0 5.2 5.4 5.6

Roger Downey Executive Officer, Coal

63 Main accomplishments • Nacala Logistics Corridor ramping up as planned, reaching 4.6 Mt ytd1 • Moatize CHPP II started up in August 2016 and produced 0.7 Mt ytd, being 0.4 Mt during hot commissioning and 0.3 Mt after its start-up mp-up • Improvements in equipment availability, utilization and throughput resulted in a record production in September 2016 (756 kt) • Moatize production increased 4% yoy1 and 40% qoq1 roductivity • • Costs and expenses2 declined 14% yoy, despite the increase in coal sales volumes Adjusted EBITDA from Mozambique operations improved more than 30% yoy, from -US$ 366 million in 9M15 to -US$ 247 million in 9M16 rgin ment 1 ytd = 9M16; yoy = 9M16 vs. 9M15; qoq = 3Q16 vs.2Q16 2 Net of depreciation Project del and ra P gains Ma improve ivery

64 The Nacala Logistics Corridor is already a reality, with growing volumes allowing an expressive cost reduction • • • Start-up in 4Q15 4.6 Mt of coal railed since start up 54 ships loaded in 9M16 Nacala Logistics Corridor – Coal train

65 The Moatize CHPP1 II plant was successfully delivered and reached 2 Mtpy run-rate in Sep-16 Moatize II –CHPP1 • • • • Start-up in Aug-16 Production in Aug-16 of 129,000 t Production in Sep-16 of 169,000 t Expected to reach 18 Mtpy run-rate by 2018 1 Coal Handling and Processing Plant

66 The Nacala and Moatize II ramp-up resulted in significantly lower costs and in EBITDA improvements Cash Costs and Expenses1 – Mozambique operations Adjusted EBITDA – Mozambique operations US$/t, FOB port US$ million -27% Adjusted EBITDA of positive US$ 31 million in Oct-16 1Q16 2Q16 3Q16 1Q16 2Q16 3Q16 1 Cost of Goods Sold, SG&A, R&D, pre-operating and stoppage and other expenses, excluding depreciation; costs are FOB port Mozambique -112 -100 -35 110 91 80

67 The ramp-up of Moatize production will contribute to further cost reductions and cash Moatize production volume, Mt generation increases 20 19 19 18 13 6 2016E 2017E 2018E 2019E 2020E 2021E Source: Vale’s budget

68 Costs in Mozambique will Production cash cost at the port1, US$/t reduce dramatically Nacala tariff 2 Production cost 1 9M16 2017E 2018E 2019E 2020E 2021E 1 Production cost includes mine, plant, railway, port and royalties and excludes inventory movement and accounting adjustments. 2 Nacala tariff is composed by debt service and other costs, such as taxes. 122 27 - 30 24 - 27 24 - 27 24 - 27 24 - 27 70 - 75 55 - 60 52 - 57 52-57 50 - 55

69 Coal business has well system mix diversified sales portfolio and pricing Sales distribution – metallurgical coal Pricing System – metallurgical coal % of sales, 2017 % of sales Index Benchmark Japan, Korea, Taiwan Atlantic India, Middle East, Africa & South America 32% 34% 34% 9M16 2017E Index based sales to increase to manage pricing volatility Geographically well distributed portfolio of metallurgical coal sales 70 34 66 30

70 Vale’s Coal EBITDA is expected to turn positive in 2017 Coal adjusted EBITDA Assumptions for 2017 US$ million • Sales volume of 13 Mt 250 - 600 - 11 Mt transported through the Nacala Logistics Corridor (NLC) - 2 Mt transported through the Sena-Beira Logistics Corridor • Production split - 65% metallurgical coal (508) - 35% thermal coal 2015 2016E 2017E • EBITDA excluding effects from Nacala tariff, i.e., before deconsolidation of the NLC (175) - (200)

Roger Downey Executive Officer, Fertilizers

72 Highlights • Average prices decreased sharply in 9M16 vs 9M15 – MAP: -28% and TSP: -25% – Potash: -16% and urea: -29% • Sales increased slightly for potash, nitrogen and DCP, while decreasing for phosphate rock, MAP and SSP in 9M16 vs 9M15 – Potash: 7%, ammonium nitrate: +3%, DCP (animal feed): +10% – Phosphate rock: -5%, MAP: -1%, SSP: -11% • Phosphate ROM replacement project is progressing well – Capex on budget – Start-up in 1H17 Pric Sales vo Replace proje e lume ment ct

73 Fertilizers MAP1 market prices decreased, impacting TSP2 business results US$/t US$/t -28% -25% 475 343 393 296 9M15 9M16 9M15 9M16 Potash3 Ammonium nitrate1 US$/t US$/t -30% -16% 226 305 255 159 9M15 1 FOB Black sea 2 FOB Morroco 3 FOB Vancouver Source: CRU Fertilizer week 9M16 9M15 9M16

74 9M16 EBITDA was strongly hit by international prices, followed by the impacts of lower EBITDA, US$ million production on costs 34 266 450 161 9M15 Foreign exchange Sales prices Volumes Cost Others 9M16 948 18

75 Fertilizers business will focus on key initiatives to maintain its market share and improve its EBITDA margin Implement Phosphate ROM Project 3 SSP strategy 1 Cost cutting Advance in value chain 2 4 1 From 2018 onwards •Direct delivery to farmers through blenders •Ongoing development of new sales channel • Procurement initiatives - Contract renegotiation - Scope of services revision - Variable and fixed cost reduction • Organizational restructuring - Fixed cost and SG&A reduction •Technical sales campaign for SSP focused on soybean •Market share increase / maintenance in key markets •Achieved 90% physical progress •Start-up: 1H17 •Capex: on budget •Phosphate rock volume: ~1.3Mtpa1

Luciano Siani Pires Chief Financial Officer

77 Re-rating of Vale’s three dimensions shares is on the back of de-risking equity story in Capex Financial Competitiveness ongoing • Closed the competitiveness gap in iron ore and base metals • Turned around loss making operations • Concluded the investment cycle bringing Vale’s CAPEX on par with peers • Reduced capital and sustaining investments with continued discipline in capital allocation • Relentless focus on reducing leverage through cash generation and divestments • Target of US$ 15 - 17 billion of net debt in 2017 leverage& P requirementsP

78 Stronger competitive position across all business segments EBITDA – Iron ore operations EBITDA – Coal operations EBITDA – Base metals operations1 1H16, US$ billion US$ million US$ million Ni price average, US$/t 3.9 1,791 1,691 3.4 38 -7 -93 2013 2016E -110 2Q16 Vale Peer 1 Peer 2 Peer 3 1Q16 3Q16 Oct/16 15,004 9,422 1 Copper price: US$ 7,322/t in 2013 and US$ 4,722/t in 2016E Continuous efforts to reduce costs and expenses helped Vale to close the competitiveness gap in 2016 2.8 1.9

79 Investments in replacement US$ billion the coming years will be mostly in sustaining and Growth approved Sustaining Replacement 5.6 2.9 2016E 2017E 2018E 2019E 2020E 2021E Note: BRL/USD exchange rate of BRL/USD 3.37 from 2017 onwards 2.4 4.54.5 0.9 4.0 2.5 1.2 3.2 2.5 3.2 0.7 0.6 2.5 2.5 2.3 1.8 1.1 0.3

80 Vale’s CAPEX to remain low in the future when compared to main peers US$ billion Vale Peer 1 -49% -58% +57% -22% 11.9 8.2 5.8 4.5 4.5 2014 2015 2016E 2017E 2018E 2014 2015 2016E 2017E 2018E Peer 2 Peer 3 -63% 0% -51% -3% 14.6 9.5 3.5 3.5 3.6 2014 2015 2016 2017E 2018E 2014 2015 2016E 2017E 2018E 5.9 11.0 6.4 5.46.2 4.73.55.05.5 8.4

81 The market expects Vale US$ billion to be free cash flow positive in 2017 10.3 4.5 1.5 0.5 0.3 0.3 0.4 0.6 2.2 Analysts' CAPEX Financial expenses, net REFIS Income tax Debt hedge settlement Payments related to Sumic² Others³ Free cash flow average 1 EBITDA 2017 1 Average of 15 banks, as of 11/24/16 2 Compromising of US$ 135 million related to their equity stake in VNC and US$ 218 million related to debt funding Sumic provided to VNC 3 Dividends paid to noncontrolling interest and others

82 Cumulative free cash flow1 can reach over US$ 19 billion by 2021 US$ billion, cumulative FCF 2017-2021E Iron prices @ US$60/t Iron prices @ US$50/t 35.0 – 37.5 bi 19.0 – 21.5 bi 9.0 - 9.5 8.5 - 9.0 7.0 - 7.5 5.5 - 6.0 5.0 - 5.5 4.0 - 4.5 3.0 - 3.5 1.5 - 2.0 2017 2018 2019 2020 2021 2017 2018 2019 2020 2021 1 FCF before divestments, dividends and debt amortization; assuming nickel prices at US$ 10,500/t in 2017, US$ 12,800/t in 2018, US$ 14,400/t in 2019, US$ 15,500/t in 2020 and US$ 17,100/t in 2021, copper prices at US$ 4,900/t in 2017, US$ 5,100/t in 2018, US$ 5,500/t in 2019, US$ 6,000/t in 2020 and US$ 6,300/t in 2021, BRL/US$ 3.37 Distribution of dividends may reach higher levels and debt will decline quickly Large distribution of dividends and quick debt reduction 6.0 - 6.5 4.5-5.0

83 Vale is constantly optimizing its debt amortization schedule Current2 debt amortization schedule Debt amortization schedule in Jan-16 US$ billion US$ billion Revolving credit lines1 Debt amortization 31.2 US$ 5 billion available in revolving credit lines 3.1 2.0 3.4 2017 2018 2019 2020 2021 onwards Total debt 2016 2017 2018 2019 2020Total debt onwards 1 US$ 3 billion of revolving credit was withdrawn in January 2016 2 As of October 31, 2016. Including the payment of the revolving facilities in 4Q16 28.4 12.4 bi 16.0 3.8 3.9 1.3 18.5 3.0 28.2 12.7 bi 4.8 1.8 16.7 1.2 2.8 3.6 3.1 2.8 2.0

84 Net debt of US$ 15-17 billion can be achieved by free cash flow generation1 with Net debt, US$ billion divestments being a strategic optionality Requires divestments up to US$ 2 billion to reach net debt target Requires divestments of US$ 2-4 billion to reach net debt target Requires divestments of US$ 4-6 billion to reach net debt target 1Figures do not include dividend payments nor future asset sales apart from the coal transaction (US$ 3 billion) in 2017 Iron ore Platts (US$/t) If prices stay firm until… 2017 2018 2019 60 16.6 9.6 2.5 55 17.9 12.6 7.1 50 19.5 15.6 11.6 45 21.2 19.3 16.7

Thank you

Table of Contents

Signatures

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

|

|

Vale S.A.

|

|

|

(Registrant)

|

|

|

|

|

|

By:

|

/s/ André Figueiredo

|

|

Date: November 29, 2016

|

|

Director of Investor Relations

|

86

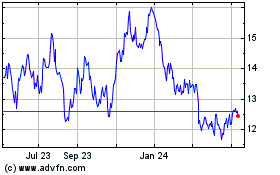

Vale (NYSE:VALE)

Historical Stock Chart

From Mar 2024 to Apr 2024

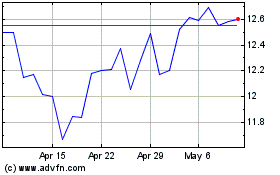

Vale (NYSE:VALE)

Historical Stock Chart

From Apr 2023 to Apr 2024