UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form SD

Specialized Disclosure Report

(Exact name of registrant as specified in its charter)

Taiwan Semiconductor Manufacturing Company Limited

(Translation of Registrant’s Name Into English)

No. 8,

Li-Hsin Road 6 Hsinchu Science Park Hsinchu, Taiwan Republic of China

(Address of principal executive offices)

Sylvia Fang, +886-3-505-5089

(Name and telephone number, including area code, of person to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 - Conflict Minerals Disclosure

Items 1.01 and 1.02 Conflict Minerals Disclosure and Report, Exhibit

Conflict Minerals Disclosure

Attached as Exhibit 1.01

hereto please see the Conflict Minerals Report for Taiwan Semiconductor Manufacturing Company Limited (“TSMC”) for the reporting period January 1, 2014 to December 31, 2014 which is also publicly available at

http://www.tsmc.com/english/investorRelations/sec_filings.htm or www.sec.gov.

TSMC’s conflict minerals disclosure and the

description of its due diligence framework, are included in its Conflict Minerals Report and incorporated by reference herein.

Section 2

– Exhibits

Item 2.01 Exhibits

Exhibit 1.01 – TSMC Conflict Minerals Report for the reporting period January 1, 2014 to December 31, 2014.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

| Taiwan Semiconductor Manufacturing Company Limited |

|

| /s/ Steven Tso |

| Steven Tso |

| Senior Vice President and Chief Information Officer |

| Date: May 22, 2015 |

|

| /s/ Sylvia Fang |

| Sylvia Fang |

| Vice President and General Counsel |

| Date: May 22, 2015 |

EXHIBIT INDEX

|

|

|

| Exhibit

Number |

|

Description |

| |

|

|

| 1.01 |

|

TSMC Conflict Minerals Report for the reporting period January 1, 2014 to December 31, 2014. |

Exhibit 1.01

TSMC CONFLICT MINERALS REPORT

I. Preliminaries

Taiwan

Semiconductor Manufacturing Company Limited (the “Company,” “TSMC,” “we,” “us” or “our”) is filing this Form SD pursuant to Rule 13p-1 under the Securities Exchange Act of 1934 for the reporting

period January 1, 2014 to December 31, 2014 (“Reporting Period”).

Rule 13p-1, through Form SD, requires the disclosure of certain

information if a company manufactures or contracts to manufacture products for which certain “conflict minerals” (“Covered Minerals” as defined below) are necessary to the functionality or production of such products. Form SD

defines “conflict minerals” as: (i)(a) columbite-tantalite (or coltan, the metal ore from which tantalum is extracted); (b) cassiterite (the metal ore from which tin is extracted); (c) gold; and (d) wolframite (the metal ore

from which tungsten is extracted), or their derivatives, or (ii) any other mineral or its derivatives determined by the U.S. Secretary of State to be financing conflict in the Democratic Republic of the Congo or an adjoining country

(collectively, the “Covered Countries”).

TSMC’s operations, including the operations of its consolidated subsidiaries, may at times

manufacture, or contract to manufacture, products for which conflict minerals are necessary to the functionality or production of those products (collectively, the “Products”). For example, the Covered Minerals, particularly tantalum, tin

and tungsten, are frequently used in our various product lines to varying degrees.

This Conflict Minerals Report describes: (i) the good faith

reasonable country of origin inquiry (“RCOI”) regarding the conflict minerals included in the Products during the period from January 1, 2014 until December 31, 2014 (the “Reporting Period”) to determine whether any of

such Covered Minerals originated in the Covered Countries and/or whether any of the Covered Minerals may be from recycled or scrap sources; (ii) the measures and framework used by us to exercise due diligence on the source and chain of custody

of our Covered Minerals; and (iii) the determination as to the facilities used to process the Covered Minerals as well as their countries of origin. There is a significant overlap between our RCOI efforts and our due diligence measures

performed as detailed herein.

II. Reasonable Country of Origin Inquiry

Form SD requires that an issuer’s reasonable country of origin inquiry must be conducted in good faith and reasonably designed to determine whether the

issuer’s Covered Minerals originated in the Covered Countries, or came from recycled or scrap sources, and it must be performed in good faith.

1

Conflict-Free Policies

As a general matter, TSMC has designed and implemented three procedural cornerstones in support of compliance with conflict-free sourcing:

(a) TSMC’s Ethics and Business Conduct Policy; (b) TSMC’s Corporate Social Responsibility Program (including TSMC’s Supplier Responsibilities for Sourcing Conflict-Free Materials), which is publicly available online at

http://www.tsmc.com/english/csr/collaborates_with_suppliers.htm); and (c) TSMC’s Green Procurement for Substance Control and Conflict Minerals Procedure (“Green Procurement Policy”). Our Ethics and Business Conduct Policy

contains general ethical principles and guidelines that, among other matters, require us to follow all applicable laws, including those related to the sourcing of conflict minerals. As part of the duties of an ethical corporate citizen, our

Corporate Social Responsibility Program describes the requirements we place upon our suppliers, such as requiring them to comply with applicable labor laws and also to source materials from conflict-free regions. Our Green Procurement Policy

requires us, as well as all of our relevant suppliers and contractors, to watch out for any “red flags” regarding the source of conflict minerals in our supply chain. Please see Exhibit III attached hereto for a description of such warning

flags. Also, in addition to imposing requirements relating to hazardous substances materials sourcing, our Green Procurement Policy requires that any of our potential suppliers or contractors adhere to our Supplier Responsibilities for Sourcing

Conflict-Free Materials. These documents serve as the basis for our strong internal corporate management system with respect to conflict-free sourcing. Secondly, TSMC adheres to the humanitarian and ethical principles contained in the

Organisation for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High Risk Areas: Second Edition, including the related supplements on gold, tin, tantalum and

tungsten (the “OECD Guidance”) to supplement its policies and procedures on conflict-free sourcing. We have adopted its due diligence framework and have designed our due diligence measures consistently with the OECD Guidance. Finally, as

an applicant member of the Electronic Industry Citizenship Coalition® (“EICC®”), TSMC has adopted the EICC® Code of Conduct which describes the EICC®’s general principle on the responsible sourcing of minerals. Even

though no current law compels us to adopt the EICC® Code of Conduct, we have nevertheless incorporated EICC® Code of Conduct principles on conflict minerals sourcing as an additional safeguard in our conflict minerals regulatory compliance

system.

Participation in Trade Association Conflict-Free Initiatives

In 2014, TSMC joined the EICC® as an applicant member with the aim of becoming a full member as soon as permitted under the EICC® bylaws. As an active

participating member of the EICC®, TSMC may better lend its influence and resources to support and help sponsor industry-wide conflict-free initiatives like the Global e-Sustainability Initiative (“GeSI”) and the Conflict-Free Sourcing

Initiative (“CFSI”)’s Conflict-Free Smelter Program (or “CFSP”).

Since 2009, the EICC® and GeSI have led efforts to develop

implementation tools and programs for the tracking of conflict minerals in the global electronics supply chain. In late 2011, TSMC was among the first in our industry to adopt and require our suppliers and contractors to use the CFSI Conflict

Minerals Reporting Template (the “Dashboard”). The Dashboard was developed by the EICC®-GeSI as a common industry standard method to collect sourcing information related to conflict minerals and is recognized in the OECD Guidance as an

important component of responsible supply chain management. As evidenced in the Form SD for fiscal year 2013 filed by almost every issuer who does business in the technology sector, gathering the information for the Dashboard mechanism constituted a

significant portion of the due diligence measures adopted by our industry peers. TSMC’s Green Procurement Policy requires our relevant suppliers and contractors (as well as the relevant suppliers and contractors of our consolidated

subsidiaries) to complete and regularly update the Dashboard. In addition, the CFSP allows independent third-party certification of the conflict-free status of participating smelters and refiners. Again, based on a review of the Form SD for fiscal

year 2013 filed by almost every issuer involved in the technology sector, the sourcing of Covered Minerals from smelters or refiners validated under the CFSP represented a major part of their respective reasonable country of origin inquiry and/or

due diligence measures. Our Green Procurement Policy encourages our suppliers and contractors to source from smelters or refineries validated under this Program.

2

Suppliers & Contractors Representations

Because TSMC does not purchase the Covered Minerals directly from smelters, refiners or mines, TSMC relies on the country of origin information provided by

its direct first-tier suppliers or contractors that supply Covered Minerals (respectively “Suppliers” and “Contractors). Our Suppliers and Contractors were asked to complete Dashboard templates, obtain representations from their

suppliers, obey our Corporate Social Responsibility Program and periodically update all information provided to us regarding conflict minerals for the Reporting Period. We obtained written representations indicating the facility at which the Covered

Minerals were processed and demonstrating whether these Covered Minerals originated in the Covered Countries or came from recycled or scrap sources. The representation letters indicated that during the Reporting Period, they either:

(i) supplied no Covered Minerals from the Covered Countries; or (ii) they supplied Covered Minerals solely from smelters or refiners that had been validated under the CFSP or were awaiting CFSP validation.

For a summary of the determinations made from our reasonable country of origin inquiry, please see Section IV: Determinations below.

III. Due Diligence Framework

TSMC’s due diligence measures have been designed to conform, in all material respects, to the framework described in the Organisation for Economic

Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High Risk Areas: Second Edition, including the related supplements on gold, tin, tantalum and tungsten (the “OECD

Guidance”), consistent with TSMC’s position as a downstream company. To guide its due diligence, TSMC has established a due diligence compliance process that includes a documentation and record maintenance mechanism performed in accordance

with TSMC’s records retention policy to ensure the retention of relevant documentation. The Company expects to continue to refine, revise and improve this process as appropriate in light of existing infrastructures regarding conflict minerals

compliance industry-wide.

Description of Due Diligence Framework

In accordance with the OECD Guidance, the Company’s due diligence measures on the source and chain of custody of Covered Minerals have been designed and

implemented on the following framework:

i) Establish strong company management systems

Policy: As discussed in Section II above, TSMC has adopted the Supplier Responsibilities for Sourcing Conflict-Free Materials viewable publicly

online (at http://www.tsmc.com/english/csr/collaborates_with_suppliers.htm) which outlines TSMC’s commitment to responsible sourcing of its Conflict Minerals in its products and its expectations that its suppliers and contractors will be

similarly committed to responsible sourcing in the supply chain. The Company has communicated our Policy to our suppliers and contractors of Covered Minerals and required them to acknowledge its importance. It is the policy of TSMC to encourage all

of our suppliers and contractors to source the Covered Minerals from smelters or refiners who have been certified by independent third parties under the CFSI’s Conflict-Free Smelter Program.

3

Personnel: To oversee compliance with relevant conflict-free materials laws and regulations, we

have formed a standing Conflict-Free Materials Task Force (“Task Force”), consisting mainly of Legal, Environmental, Safety & Health, Procurement, and Backend Technology and Service. This cross-functional group is responsible for

implementing TSMC’s conflict minerals compliance strategy. The Task Force is sponsored by senior management, including the Vice President & General Counsel as well as the Senior Vice President and Chief Information Officer. Our senior

management and the Board of Directors’ Audit Committee are briefed about the results of the Company’s due diligence efforts where they provide guidance and oversight. The Task Force identifies and assesses the relevant risks in our supply

chain and formulates and implements control points to manage such risks. The Task Force also works closely with our internal team dedicated to managing all EICC® related membership obligations such as complying with the EICC® Code of Conduct

relating to the responsible sourcing of minerals.

Supplier Engagement: The Task Force contacted our Suppliers and Contractors to provide

them with notice of the relevant U.S. SEC requirements and advised them of the Company’s commitment to responsibly source materials and its due diligence expectations, and has followed up with each Supplier and Contractor as was reasonable to

ensure compliance. In addition, the Company has posted its Supplier Responsibilities for Sourcing Conflict-Free Materials on its website so that these entities may understand and acknowledge it as a condition for doing business with us. The Company

intends to retain evidence of the received Supplier and Contractor responses as part of its RCOI and due diligence. Feedback from this process will be used to modify, where appropriate, the design of TSMC’s Conflict Minerals compliance program.

Grievance Mechanism: The Company’s existing procedures for reporting code of conduct or other ethics violations are available for

reporting Conflict Minerals compliance problems. Any party who has relevant information is able to file anonymous complaints via either the Ombudsman complaint system or Audit Committee whistleblower system. All informants are protected from

retaliation under the Ethics and Business Conduct Policy to encourage the frank and full disclosure of grievances.

4

ii) Identify and Assess Risk in the Supply Chain

Identification of Risk: To identify risks in its supply chain, the Task Force through the contact window of the Procurement team contacted and

requested its Suppliers and Contractors to complete the Dashboard and include information regarding the source and chain of custody of Conflict Minerals in its supply chain. To facilitate the collection of complete, accurate, standardized and

verifiable information, the Company relied primarily on the Dashboard made available by the CFSI. The information provided on the Dashboard facilitates the transfer of information through the supply chain regarding country of origin and smelters and

refiners used. Written instructions and recorded training illustrating the use of the Dashboard are available on CFSI’s website. The Task Force has created follow-up processes (including e-mail communication) to identify and escalate any

identified issues associated with non-responsive or problematic responses to its inquiry. As part of these processes, the Task Force expects to review the Dashboard and other information provided by its suppliers and contractors to assess the

reasonableness of the responses and to look for inconsistencies or other apparent inaccuracies.

Assessment of Risk: Upon receipt of

completed Dashboards from its suppliers and contractors, the Task Force conducts due diligence of identified smelters or refiners by examining the information provided in Dashboard to determine if the smelter or refiner has been validated under the

CFSP as “conflict-free”, and assess potential risks in its supply chain. The CFSP provides information regarding those smelters or refiners that, following an independent third-party audit, have been found to be compliant with the

CFSP’s assessment protocols to assure sourcing of only conflict-free materials.

iii) Design and Implement a Strategy to

Respond to Identified Risks

and Implementation of Control Points

TSMC’s Task Force takes the following actions, among others, to improve its due diligence measures, increase supply chain transparency and further

mitigate the risk that the Covered Minerals contained in its products may finance or benefit armed groups in the Covered Countries. These actions taken serve as control points in our compliance effort.

| • |

|

communicate our conflict mineral program to all relevant parties and make same available publicly online; |

| • |

|

design a compliance framework in accordance with the OECD Guidelines; |

| • |

|

request suppliers and contractors to complete a Dashboard and review results of same; |

| • |

|

update the Dashboard template as required; |

| • |

|

request relevant parties sign representation letter confirming their compliance with our conflict mineral program, and requiring them to conduct similar inquiries in their supply chain; |

| • |

|

request our relevant suppliers and contractors use only smelters and refiners certified or have entered into the certification process conducted under the CFSP; |

| • |

|

check whether TSMC suppliers are listed as certified under the CFSP (such as consulting the CFSI’s website); |

| • |

|

compile a list of suppliers, contractors and their smelters or refiners as well as their respective locations; |

| • |

|

provide such list to government agencies and the public if or when required by law; |

| • |

|

discuss compliance status with materials suppliers or contractors; |

| • |

|

conduct conflict minerals compliance training as applicable; |

5

| • |

|

research publicly available information to check whether high risk smelters or refiners identified by the Task Force indirectly or directly finance or benefit armed groups in the Covered Countries; |

| • |

|

watch out for warning flags as identified in Exhibit III attached hereto; |

| • |

|

participate in relevant industry discussions on conflict minerals compliance such as those conducted under the EICC®; |

| • |

|

assist with conflict minerals compliance audits conducted by our customers and investors; |

| • |

|

discuss our conflict minerals compliance efforts with our customers or investors when required; |

| • |

|

reassure our major investor(s) that conflict minerals compliance is an integral part of our corporate governance scheme; |

| • |

|

continue to collect Covered Minerals information contained in our finished products manufactured for all relevant periods; |

| • |

|

continue to engage suppliers and contractors to obtain current, accurate and complete information about the supply chain, smelters and refiners; |

| • |

|

enhance supplier or contractor communication, training and escalation process to improve due diligence data accuracy and completion; and |

| • |

|

encourage suppliers and contractors to implement responsible sourcing and to request that their suppliers or contractors encourage smelters and refiners to obtain a “conflict-free” designation from an

independent, third-party auditor such as the CFSI’s Conflict-Free Smelter Program. |

iv) Carry Out Independent

Third-Party Audit of Supply Chain

TSMC does not have any direct relationships with smelters or refiners that process the Covered Minerals,

and it does not perform or direct audits of our conflict minerals smelters or refiners. Instead, the Company relies on information provided by its suppliers and contractors, and on information collected and provided by independent third-party audit

programs, such as the CFSP as well as other publicly available information.

TSMC has also been regularly audited by some of its customers as to the

sufficiency of its conflict minerals compliance program. To date, TSMC has successfully passed these customer audits (most of which have imposed requirements that are more stringent than those issued by the U.S. SEC) and shall continue to work with

our customers and suppliers in building a conflict-free supply chain for the Covered Minerals over time.

v) Report Annually on

Supply Chain Due Diligence:

Public Reporting of our Conflict-Free Materials Compliance

TSMC expects to report annually, as required by the U.S. SEC, and the contents of this Form SD describing the methodology of our reasonable inquiry analysis

and due diligence measures may be accessed publicly online at http://www.tsmc.com/english/investorRelations/sec_filings.htm or www.sec.gov.

6

IV. Determinations

Our determination as to the origins and chain of custody of our Covered Minerals is based on the reasonable country of origin inquiry and due diligence

measures described above and expressly subject to the Cautionary Statements set forth below.

Exhibit I lists the smelters and refiners reasonably

identified by our due diligence measures based on information provided by our materials suppliers and contractors known to have processed the Covered Minerals in our Products during the Reporting Period.

Exhibit II lists the countries of origin of the Covered Minerals in our Products as reasonably identified by our due diligence measures, and based on

information from our relevant suppliers and contractors.

For the Reporting Period, our Covered Minerals used in our Products originated from fourteen

direct first-tier suppliers who used thirty-one smelters or refiners; thirty of which have been validated by the CFSP with the remaining one undergoing the validation process. During the Reporting Period, the Covered Minerals used in our Products

also originated from nine contractors who in turn used fifty-eight smelters or refiners; fifty-two of which have been validated by the CFSP with the rest undergoing the validation process. Some of our suppliers or contractors were unable to provide

information on some of the countries of origin of the Covered Minerals supplied or used by its smelters or refiners.

Out of the identified smelters or

refiners, five appeared to have supplied Covered Minerals sourced from the Covered Countries, and all five had been validated under the CFSP. To date, validation under the CFSP has been accepted by our industry as the primary standard for

determining whether a smelter or refiner process Covered Minerals that directly or indirectly finance or benefit armed groups. Like our industry peers, TSMC relies on the independent third-party audits conducted under the CFSP as furnishing a

reasonable basis to conclude that smelters and refiners validated under such Program have control procedures that prevent them from directly or indirectly financing or benefiting armed groups operating in the Covered Countries. Because of industry

acceptance of the CFSI’s Conflict-Free Smelter Program and based on its own research of publicly available information, TSMC found no reasonable basis for independently determining that these validated smelters and refiners, or those awaiting

validation, sourced Covered Minerals that directly or indirectly finance or benefit armed groups in the Covered Countries.

Cautionary Statements

Our

reasonable country of origin inquiry as well as our due diligence measures have endeavoured to overcome the unavoidable limitations inherent in collecting information about the origins and chain of custody of the Covered Minerals used in our

finished products as a downstream purchaser of the Covered Minerals operating within a complex international electronics supply chain. As such, we rely on our suppliers and contractors for the ultimate veracity of the information which they provide

about the smelters or refiners whom they employ because we do not have any direct contractual relationship with or power of control over such smelters or refiners. Information that have been subjected to fraud by third parties may elude detection

even after having been subjected to the most robust verification due diligence measures like the ones we have adopted and implemented for the Reporting Period. In spite of these difficulties, our determination made herein stands as reasonable

assurance of the current status of our conflict minerals compliance and in no way detracts from our commitment towards creating a conflict-free supply chain for our Products in the coming years when infrastructures that further facilitate conflict

minerals compliance would become more prevalent, established and readily available at reasonable cost in time and resources.

7

Exhibit I

Smelters & Refiners

|

|

|

|

|

| Conflict Minerals |

|

Smelter/Refiner |

|

Location |

|

|

|

| Gold |

|

Western Australian Mint trading as The Perth Mint |

|

AUSTRALIA |

|

|

|

| Gold |

|

CCR Refinery – Glencore Canada Corporation |

|

CANADA |

|

|

|

| Gold |

|

Royal Canadian Mint |

|

CANADA |

|

|

|

| Gold |

|

Allgemeine Gold-und Silberscheideanstalt A.G. |

|

GERMANY |

|

|

|

| Gold |

|

Heraeus Ltd. Hong Kong |

|

HONG KONG |

|

|

|

| Gold |

|

Metalor Technologies (Hong Kong) Ltd |

|

HONG KONG |

|

|

|

| Gold |

|

Asahi Pretec Corporation |

|

JAPAN |

|

|

|

| Gold |

|

Eco-System Recycling Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

Ishifuku Metal Industry Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

JX Nippon Mining & Metals Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

Matsuda Sangyo Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

Mitsubishi Materials Corporation |

|

JAPAN |

|

|

|

| Gold |

|

Mitsui Mining and Smelting Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

Nihon Material Co. LTD |

|

JAPAN |

|

|

|

| Gold |

|

Sumitomo Metal Mining Co., Ltd. |

|

JAPAN |

|

|

|

| Gold |

|

Tanaka Kikinzoku Kogyo K.K. |

|

JAPAN |

8

|

|

|

|

|

| Conflict Minerals |

|

Smelter/Refiner |

|

Location |

|

|

|

| Gold |

|

Tokuriki Honten Co., Ltd |

|

JAPAN |

|

|

|

| Gold |

|

Argor-Heraeus SA |

|

SWITZERLAND |

|

|

|

| Gold |

|

Metalor Technologies SA |

|

SWITZERLAND |

|

|

|

| Gold |

|

Republic Metals Corporation |

|

UNITED STATES |

|

|

|

| Gold |

|

United Precious Metal Refining, Inc. |

|

UNITED STATES |

|

|

|

| Gold |

|

Metalor USA Refining Corporation |

|

UNITED STATES |

|

|

|

| Tin |

|

Metallo Chimique |

|

BELGIUM |

|

|

|

| Tin |

|

EM Vinto |

|

BOLIVIA |

|

|

|

| Tin |

|

OMSA |

|

BOLIVIA |

|

|

|

| Tin |

|

Mineração Taboca S.A. |

|

BRAZIL |

|

|

|

| Tin |

|

Cooper Santa |

|

BRAZIL |

|

|

|

| Tin |

|

Magnu’s Minerais Metais e Ligas LTDA |

|

BRAZIL |

|

|

|

| Tin |

|

Soft Metais, Ltda. |

|

BRAZIL |

|

|

|

| Tin |

|

White Solder Metalurgia e Mineração Ltda. |

|

BRAZIL |

|

|

|

| Tin |

|

Gejiu Non-Ferrous Metal Processing Co. Ltd. |

|

CHINA |

|

|

|

| Tin |

|

Yunnan Tin Company, Ltd. |

|

CHINA |

|

|

|

| Tin |

|

China Tin Group Co., Ltd. |

|

CHINA |

|

|

|

| Tin |

|

Yunnan Chengfeng Non-ferrous Metals Co.,Ltd. |

|

CHINA |

|

|

|

| Tin |

|

CV United Smelting |

|

INDONESIA |

|

|

|

| Tin |

|

PT Bangka Putra Karya |

|

INDONESIA |

|

|

|

| Tin |

|

PT Tambang Timah |

|

INDONESIA |

|

|

|

| Tin |

|

PT Bangka Tin Industry |

|

INDONESIA |

|

|

|

| Tin |

|

PT Stanindo Inti Perkasa |

|

INDONESIA |

9

|

|

|

|

|

| Conflict Minerals |

|

Smelter/Refiner |

|

Location |

|

|

|

| Tin |

|

PT Timah (Persero), Tbk |

|

INDONESIA |

|

|

|

| Tin |

|

PT Bukit Timah |

|

INDONESIA |

|

|

|

| Tin |

|

PT Eunindo Usaha Mandiri |

|

INDONESIA |

|

|

|

| Tin |

|

PT Mitra Stania Prima |

|

INDONESIA |

|

|

|

| Tin |

|

PT Refined Bangka Tin |

|

INDONESIA |

|

|

|

| Tin |

|

PT Sariwiguna Binasentosa |

|

INDONESIA |

|

|

|

| Tin |

|

PT Tinindo Inter Nusa |

|

INDONESIA |

|

|

|

| Tin |

|

Mitsubishi Materials Corporation |

|

JAPAN |

|

|

|

| Tin |

|

Malaysia Smelting Corporation (MSC) |

|

MALAYSIA |

|

|

|

| Tin |

|

Minsur |

|

PERU |

|

|

|

| Tin |

|

Fenix Metals |

|

POLAND |

|

|

|

| Tin |

|

Rui Da Hung |

|

TAIWAN |

|

|

|

| Tin |

|

Thaisarco |

|

THAILAND |

|

|

|

| Tin |

|

Alpha |

|

UNITED STATES |

|

|

|

| Tungsten |

|

Xiamen Tungsten Co., Ltd |

|

CHINA |

|

|

|

| Tungsten |

|

Xiamen Tungsten (H.C.) Co., Ltd |

|

CHINA |

|

|

|

| Tungsten |

|

Ganzhou Seadragon W & Mo Co., Ltd. |

|

CHINA |

|

|

|

| Tungsten |

|

Chongyi Zhangyuan Tungsten Co Ltd |

|

CHINA |

|

|

|

| Tungsten |

|

Ganzhou Huaxing Tungsten Products Co., Ltd. |

|

CHINA |

|

|

|

| Tungsten |

|

Hunan Chunchang Nonferrous Metals Co., Ltd. |

|

CHINA |

|

|

|

| Tungsten |

|

Global Tungsten & Powders Corp. |

|

UNITED STATES |

10

|

|

|

|

|

| Conflict Minerals |

|

Smelter/Refiner |

|

Location |

|

|

|

| Tantalum |

|

Ningxia Orient Tantalum Industry Co., Ltd. |

|

CHINA |

|

|

|

| Tantalum |

|

H.C. Starck GmbH Goslar |

|

GERMANY |

|

|

|

| Tantalum |

|

H.C. Starck GmbH Laufenburg |

|

GERMANY |

|

|

|

| Tantalum |

|

H.C. Starck Hermsdorf GmbH |

|

GERMANY |

|

|

|

| Tantalum |

|

H.C. Starck Smelting GmbH & Co.KG |

|

GERMANY |

|

|

|

| Tantalum |

|

H.C. Starck Ltd. |

|

JAPAN |

|

|

|

| Tantalum |

|

Ulba |

|

KAZAKHSTAN |

|

|

|

| Tantalum |

|

H.C. Starck Co., Ltd. |

|

THAILAND |

|

|

|

| Tantalum |

|

H.C. Starck Inc. |

|

UNITED STATES |

|

|

|

| Tantalum |

|

Global Advanced Metals Boyertown |

|

UNITED STATES |

11

EXHIBIT II

Conflict Minerals: Countries of Origin

Australia

Bolivia

Brazil

Canada

China

Ethiopia

Germany

India

Indonesia

Japan

Mozambique

Namibia

Russia

Rwanda

Sierra Leone

Thailand

United States

Zimbabwe

12

EXHIBIT III

Warning Flags

Warning Flag

Situations:

| • |

|

minerals originate from or have been transported via a conflict area; |

| • |

|

minerals are claimed to originate from a country that has limited known reserves; |

| • |

|

minerals are claimed to originate from a country in which minerals from conflict areas are known to transit; |

| • |

|

suppliers or other known upstream companies have shareholder or other interests in companies that supply minerals from or operate in conflict area; |

| • |

|

suppliers or other known upstream companies are known to have sourced mineral from a warning flag location of mineral origin and transit in the last 12 months. |

(From “Supplement on Tin, Tantalum and Tungsten” in OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and

High-Risk Areas (OECD 2011, p. 31)).

13

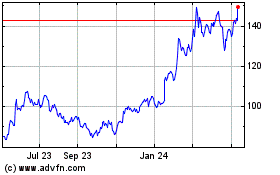

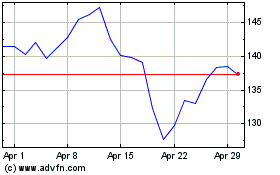

Taiwan Semiconductor Man... (NYSE:TSM)

Historical Stock Chart

From Mar 2024 to Apr 2024

Taiwan Semiconductor Man... (NYSE:TSM)

Historical Stock Chart

From Apr 2023 to Apr 2024