UNITED STATES SECURITIES AND EXCHANGE COMMISSION

Washington D.C. 20549

FORM SD

Specialized Disclosure Report

Spirit AeroSystems Holdings, Inc.

(Exact name of registrant as specified in its charter)

|

| | | | |

Delaware | | 001-33160 | | 20-2436320 |

(State of incorporation) | | (Commission File Number) | | (I.R.S. Employer Identification No.) |

3801 South Oliver

Wichita, Kansas 67210

(Address of principal executive offices and zip code)

William Bair

(316) 526-9000

(Name and telephone number, including area code, of the person to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

ý Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014.

Section 1 - Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

This Form SD of Spirit AeroSystems Holdings, Inc. (the “Company”) is filed pursuant to Rule 13p-1 promulgated under the Securities Exchange Act of 1934, as amended, for the reporting period January 1, 2014 to December 31, 2014.

A copy of the Company’s Conflict Minerals Report is filed as Exhibit 1.01 hereto and is publicly available at http://www.spiritaero.com.

Item 1.02 Exhibit

As specified in Section 2, Item 2.01 of this Form SD, the Company is hereby filing its Conflict Minerals Report as Exhibit 1.01 to this report.

Section 2 - Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this report:

Exhibit 1.01 - Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

SPIRIT AEROSYSTEMS HOLDINGS, INC.

|

| | | | |

Signature | | Title | | Date |

| | | | |

/s/ Duane Hawkins | | Senior Vice President - Operations and | | June 1, 2015 |

Duane Hawkins | | Defense Programs | | |

Exhibit Index

|

| | | |

Exhibit No. | | Description |

| | |

1.01 |

| | Conflict Minerals Report of Spirit AeroSystems Holdings, Inc. |

Exhibit 1.01

Spirit AeroSystems Holdings, Inc.

Conflict Minerals Report

For the reporting period from January 1, 2014 to December 31, 2014

This is the Conflict Minerals Report (“CMR”) of Spirit AeroSystems Holdings, Inc. (“the Company”) prepared in accordance with Rule 13p-1 (“Rule 13p-1”) and Form SD promulgated under the Securities Exchange Act of 1934 as amended (the “1934 Act”).

Introduction

Rule 13p-1 requires disclosure of certain information when a company manufactures or contracts to manufacture products for which the minerals specified in such Rule are necessary to the functionality or production of those products. The specified minerals are gold, columbite-tantalite (coltan), cassiterite and wolframite, including their derivatives, which are limited to tantalum, tin and tungsten (the “Conflict Minerals”). The “Covered Countries” for the purposes of Rule 13p-1 are the Democratic Republic of the Congo, the Republic of the Congo, the Central African Republic, South Sudan, Uganda, Rwanda, Burundi, Tanzania, Zambia and Angola.

The Company is an independent non-OEM aircraft parts designer and manufacturer of aerostructures, such as fuselages, propulsion systems and wing systems for commercial and military aircraft. The Company’s operations include certain products for which Conflict Minerals are necessary to their functionality or production.

Description of the Company’s Products Covered by this CMR

This CMR relates to products: (i) for which Conflict Minerals are necessary to the functionality or production of that product; (ii) that were manufactured, or contracted to be manufactured, by the Company; and (iii) for which the manufacture was completed during calendar year 2014.

These products, which are referred to in this CMR collectively as the “Covered Products,” are the following: Forward Fuselage, Mid-section Fuselage Sections, Nacelles, Struts/Pylons, Flight Control Surfaces, and Wing Structures.

The Company’s Conflict Minerals Policy

The Company is committed to the responsible sourcing of minerals throughout its global supply chain. In 2012, the U.S. Securities and Exchange Commission (“SEC”) issued a “conflict minerals” rule, as mandated by the Dodd-Frank Wall Street Reform and Consumer Protection Act (“Dodd-Frank”), which requires specified disclosures with respect to Conflict Minerals which may have originated in the Covered Countries in products manufactured or contracted to be manufactured by the Company. We are committed to complying with the Dodd-Frank disclosure requirements.

OUR GOALS:

| |

• | Support the aims and objectives of the U.S. legislation on the supply of Conflict Minerals. |

| |

• | Do not knowingly procure Conflict Minerals from sources that directly or indirectly benefit or finance armed groups in the Covered Countries. |

| |

• | Encourage our suppliers to establish policies, due diligence frameworks, and management systems consistent with the Organization for Economic Co-operation and Development (OECD) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas that are designed to accomplish this goal, and request their suppliers to do the same. |

| |

• | Encourage our suppliers to undertake reasonable due diligence with their supply chains in an effort to assure that our Conflict Minerals are being sourced only from: |

| |

◦ | Mines and smelters/refiners outside the Covered Countries or |

| |

◦ | Mines and smelters/refiners which have been certified by an independent third party as “conflict free” if sourced within the Covered Countries |

Our intention is not to ban procurement of minerals from the DRC and adjoining countries, but to assure procurement from responsible sources in the region. If we determine that any of our products or components contain Conflict Minerals from a mine or facility in a Covered Country that is not “conflict free,” we intend to work towards transitioning to products/components that are “conflict free.”

The Company’s Due Diligence Process

In accordance with Rule 13p-1, the Company has conducted a good faith reasonable country of origin inquiry (“RCOI”) regarding its necessary Conflict Minerals. This RCOI was reasonably designed to determine whether any of such Conflict Minerals originated in one or more of the Covered Countries, or whether any of such Conflict Minerals are from recycled or scrap sources. The Company also exercised due diligence on the source and chain of custody of such Conflict Minerals, as based on its RCOI, the Company had reason to believe that some of such Conflict Minerals may have originated in the Covered Countries and may not be from recycled or scrap sources. Note that there is significant overlap between our RCOI and the due diligence measures we performed (described below).

The Company made an internal assessment (based on statements of work, bills of materials, and the results of its due diligence efforts from the prior year reporting period) of which of its products and components contain or may contain Conflict Minerals. Based upon that internal assessment, the Company identified and contacted those of its manufacturing suppliers which it determined were or may be “in-scope” under Rule 13p-1 ("Relevant Suppliers"). Such contact included an e-mail communication (or hard copy for undeliverable addresses) to all Relevant Suppliers describing the Company’s reporting requirements under, and the supplier’s responsibility to help enable the Company to comply with, Rule 13p-1. In order to collect information about the presence and sourcing of Conflict Minerals in the Company’s products and components, this initial communication also included the Electronic Industry Citizenship Coalition and Global e-Sustainability Conflict Minerals Reporting Template (“EICC/GeSI CMRT”) for such suppliers to complete, and specified a reasonable deadline for such completion. The Company sent a reminder communication to all Relevant Suppliers of such deadline as well. Further, the Company provided such communication and the EICC/GeSI CMRT on its Supplier web Portal.

With respect to 2014, the Company surveyed a total of 325 Relevant Suppliers and received a total of 77 responses (after all follow-up communications described in the due diligence discussion below). Of the 77 responses, 29 Relevant Suppliers responded that such supplier’s products contained Conflict Minerals, however none specifically indicated the country of origin of such Conflict Minerals or whether such Conflict Minerals were used in products or components supplied to the Company. Of the 77 responses, 21 identified smelters/refiners (“SORs”) used by such suppliers in the production of such suppliers’ products, however none of the 21 indicated which SORs processed Conflict Minerals used in products or components supplied to the Company.

In conducting its due diligence, the Company followed the OECD Due Diligence Guidance for Responsible Supply Chain of Minerals from Conflict-Affected and High-Risk Areas: Second Edition, including the related supplements on gold, tin, tantalum and tungsten (“OECD Guidance”), an internationally recognized due diligence framework. The Company’s supply chain is complex, and there are many third parties in the supply chain between the ultimate manufacture of the Covered Products and the original sources of Conflict Minerals. The Company does not purchase Conflict Minerals directly from mines, smelters or refiners. The Company must therefore rely on its suppliers to provide information regarding the origin of Conflict Minerals that are included in the Covered Products. Moreover, the Company believes that the smelters and refiners of the Conflict Minerals are best situated to identify the sources of Conflict Minerals.

The OECD Guidance identifies five due diligence steps:

Step 1: Establish Strong Company Management Systems

Step 2: Identify and Assess Risks in the Supply Chain

Step 3: Design and Implement a Strategy to Respond to Identified Risks

Step 4: Carry out Independent Third-Party Audit of Smelter/Refiner’s Due Diligence

Step 5: Report Annually on Supply Chain Due Diligence

The following constitute the procedures the Company used to identify supply chain risks in relation to Conflict Minerals in the Covered Products, and the due diligence activities undertaken to respond to those risks.

| |

1. | Establish strong company management systems |

| |

a. | We have established and maintain a cross-departmental team that includes members from the Finance, Supply Chain, Engineering, and Legal departments, which meets on a periodic basis during each reporting period, with participation from external advisers from time to time. |

| |

b. | The Company's Conflict Minerals Policy (described above and located on the Company's website) incorporates the standards set forth in the OECD Guidance and is reviewed periodically. |

| |

c. | We maintain internal operating instructions which document the areas of responsibility and deliverables for each affected department. |

| |

2. | Identify and assess risks in the Company's supply chain |

| |

a. | We identified (through bills of materials, statements of work, and the results of our due diligence efforts from the prior year reporting period) all materials used in the Company's production of aerostructures which may contain necessary Conflict Minerals. |

| |

b. | We identified all Relevant Suppliers through internal supply chain management and accounting systems. |

| |

3. | Design and implement a strategy to respond to the risks |

| |

a. | We executed an action plan for supply chain surveys (which included sending letters or emails to all Relevant Suppliers informing them of our expectation that they help enable us to comply with Rule 13p-1) and any required follow-up in order to perform a RCOI and subsequent due diligence. |

| |

b. | We conducted a RCOI with all of our Relevant Suppliers using a supply-chain survey which incorporated the EICC/GeSI CMRT to help identify whether any necessary Conflict Minerals are included in the products or components supplied to the Company by such suppliers, and if so, their country of origin as well as identify whether such suppliers have performed their own due diligence. |

| |

c. | In addition to the supply-chain survey, we identified any relevant information reported by the supplier or available within the public domain (or the Company's records) which might indicate that the Company's necessary Conflict Minerals originated in one of the Covered Countries. |

| |

d. | We analyzed Relevant Supplier responses based on the supplier's statement of work and bills of materials to aid in the determination as to whether such responses were consistent with the Company’s expectations. The Company communicated with suppliers whose responses were found to be incomplete in an effort to determine with specificity whether Conflict Minerals were contained in products or components supplied to the Company by such suppliers, and if so, their country or origin and relevant SORs. The Company also sent additional notifications to all unresponsive Relevant Suppliers. The Company received no response (to either the initial communication or any follow-up inquiries) from any Relevant Supplier indicating that Conflict Minerals in the Covered Products were from Covered Countries or benefited or financed armed groups therein. |

| |

e. | For products that the Company designs or over which the Company has direct manufacturing control, if a risk is identified, the Company will express its concerns with its suppliers about providing revenue to armed groups within the Covered Countries; and if a risk is identified, how to manage and/or mitigate the risk. The Company noted no such risk in its due diligence for the 2014 reporting period. |

| |

4. | Carry out independent third-party audit of smelter/refiner’s due diligence |

As no direct relationship exists between the Company and SOR, the Company does not perform or direct audits of these entities within our supply chain. However, downstream companies (like the Company) can support these audits by supporting or joining industry organizations. The Company is a member of the AIA, which is a trade association representing major aerospace and defense manufacturers and suppliers in the United States of America. The AIA created a Conflict Minerals Working Group ("CMWG") which is tasked to provide education and best practices tools to help support Conflict Minerals control and responsible sourcing. The CMWG, among other activities, participated in the OECD Due Diligence Pilot Program. In addition, the Company relied on the Conflict Free Sourcing Initiative and its Conflict Free Smelter Program (or "CFSP") to identify smelters who were found to be compliant with the CFSP assessment protocol, and incorporated that list, or reference thereto, into the supply-chain survey the Company sent to its Relevant Suppliers for their information.

| |

5. | Report annually on supply chain due diligence |

| |

a. | Our Conflict Minerals team provided management with periodic process updates during the reporting period and through the Form SD filing date. |

| |

b. | Our Conflict Minerals team informed management of due diligence efforts and results with respect to the reporting period. |

| |

c. | We completed and filed this Conflict Minerals Report, and the Form SD to which it relates. |

Based upon the due diligence as described above (and given the response rate of the Company’s Relevant Suppliers, and the lack of specificity of information obtained from responding suppliers), the Company was unable to conclude whether the necessary Conflict Minerals in the Covered Products originated in the Covered Countries and, if so, whether they were from recycled or scrap sources, or came from sources that directly or indirectly financed or benefited armed groups, as such term is defined in Rule 13p-1. As described above, none of the 29 responding Relevant Suppliers that indicated that such suppliers’ products contained Conflict Minerals indicated the country of origin of such Conflict Minerals, or whether such Conflict Minerals were used in the Company’s products or components. Further, as described above, the Company was unable to determine or describe the facilities used to process its necessary Conflict Minerals in the Covered Products or determine their mine(s) or location of origin, as no SOR information obtained was specific to the Company’s products or components. The Company’s efforts to identify the specific mine or location of origin of the Conflict Minerals included the use of the due diligence measures described above.

In the next compliance period, the Company intends to implement steps to improve the information gathered from its due diligence and further mitigate the risk that its necessary Conflict Minerals finance or benefit armed groups. The anticipated steps include: (i) use current compliance period supplier responses to refine the next compliance period inquiry and follow-up procedures; (ii) increase the level and specificity of information requested and obtained from suppliers; (iii) review and update the list of products and associated suppliers designated as “in scope” with respect to Rule 13p-1; (iv) continue to engage with suppliers to obtain current, accurate and complete information about the supply chain and supply chain participants closer to the SOR; (v) engage with Relevant Suppliers that did not provide responses for 2014 to obtain information from them in subsequent reporting periods; (vi) participate in industry initiatives encouraging “conflict-free” supply chains; and (vii) continue to implement our new supplier protocol to incorporate the EICC/GeSI CMRT as part of a supplier’s contract set-up process.

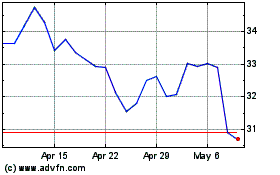

Spirit Aerosystems (NYSE:SPR)

Historical Stock Chart

From Mar 2024 to Apr 2024

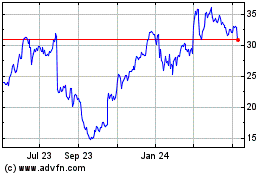

Spirit Aerosystems (NYSE:SPR)

Historical Stock Chart

From Apr 2023 to Apr 2024