UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

SCHLUMBERGER N.V.

(SCHLUMBERGER LIMITED)

(Exact name of registrant as specified in its charter)

|

|

|

|

|

Curaçao

|

|

1-4601 |

|

52-0684746

|

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

|

|

|

| 42, rue Saint-Dominique

Paris, France |

|

|

|

75007 |

|

|

|

| 5599 San Felipe, 17th Floor

Houston, Texas United States of America |

|

|

|

77056 |

|

|

|

| 62 Buckingham Gate

London, United Kingdom |

|

|

|

SW1E 6AJ |

|

|

|

| Parkstraat 83, The Hague,

The Netherlands |

|

|

|

2514 JG |

| (Addresses of principal executive offices) |

|

|

|

(Zip Codes) |

Saul R. Laureles

Deputy General Counsel

(713) 513-2000

(Name and telephone number, including area code, of the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1, 2014 to December 31, 2014. |

Section 1 — Conflict Minerals Disclosure

Items 1.01 and 1.02 Conflict Minerals Disclosure and Report; Exhibit

Conflict Minerals Disclosure

In

accordance with Rule 13p-1 under the Securities Exchange Act of 1934, as amended, Schlumberger Limited (the “Company”) has filed this Specialized Disclosure Report and the Conflict Minerals Report attached hereto as Exhibit 1.01 for the

year ended December 31, 2014. Both of these documents are publicly available on the Company’s website at: http://www.slb.com/about/global_citizenship/conflict_minerals.aspx.

Section 2 – Exhibits

Item 2.01

Exhibits

Exhibit 1.01 – Conflict Minerals Report.

SIGNATURES

Pursuant to the requirements

of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

|

| SCHLUMBERGER LIMITED |

|

| /s/ Alexander C. Juden |

| Alexander C. Juden |

| Secretary and General Counsel |

|

| Date: May 27, 2015 |

1

Exhibit 1.01

SCHLUMBERGER LIMITED

CONFLICT MINERALS REPORT

FOR THE YEAR ENDED DECEMBER 31, 2014

This Conflict Minerals Report (the “Report”) of Schlumberger Limited has been prepared pursuant to Rule 13p-1 and Form

SD (the “Rule”) promulgated under the Securities Exchange Act of 1934, as amended, for the reporting period from January 1, 2014 to December 31, 2014.

All references in this Report to “Schlumberger,” “Company,” “we,” “us” or “our” are to

Schlumberger Limited (Schlumberger N.V., incorporated in Curaçao) and its consolidated subsidiaries.

As an oilfield services

company, Schlumberger is the world’s leading supplier of technology, integrated project management and information solutions to the international oil and gas exploration and production industry. Schlumberger operates in each of the major

oilfield service markets, managing its business through three Groups — Reservoir Characterization, Drilling and Production — each consisting of a number of technology-based service and product lines.

The Rule requires disclosure of certain information when a company manufactures or contracts to manufacture products for which specified

minerals are necessary to the functionality or production of those products. The specified minerals are gold, columbite-tantalite (coltan), cassiterite and wolframite, including their derivatives, which are limited to tantalum, tin and tungsten

(“conflict minerals”).

Description of Products Covered by this Report

This Report relates to products sold: (a) that contain conflict minerals necessary to their functionality or production

(“necessary conflict minerals”); (b) that we had reason to believe may have originated in the Democratic Republic of the Congo or an adjoining country (the “covered countries”) and may not have

come from recycled or scrap sources; and (c) that we manufactured, or contracted to be manufactured, in 2014 (the “covered products”). The covered products, organized by Group, are as follows: Reservoir

Characterization — permanent multiphase meters; subsea safety valves; oil, gas and core analysis laboratory equipment; seismic land acquisition systems; perforating hardware and accessories; Drilling — downhole drilling tools;

solids and pressure control equipment for drilling fluids systems; data acquisition equipment for drilling operations; Production — surface and downhole completions tools; artificial lift pumps; stimulation pumping and cementing

equipment; and groundwater monitoring products.

Due Diligence Design and Process

Our due diligence efforts were designed to conform in all material respects to the framework in the Organisation for Economic Co-operation and

Development’s “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and related Supplements on Gold and on Tin, Tantalum and Tungsten (collectively, the “OECD

Guidance”).

The following is a description of the measures that we took to exercise due diligence on the source and chain of

custody of necessary conflict minerals contained in our covered products.

1

Step 1: Company Management Systems

Conflict Minerals Policy

We have adopted

a policy relating to conflict minerals in our products (the “Conflict Minerals Policy”), incorporating relevant standards contained in the OECD Guidance, which is available at

http://www.slb.com/about/global_citizenship/conflict_minerals.aspx. The Conflict Minerals Policy iterates our commitment to responsibly source materials from suppliers that share our values. It reflects our expectation that our immediate

(“Tier 1”) suppliers will perform due diligence similar to ours on the sources of conflict minerals in their supply chains, and our expectation that they will require their own suppliers to do the same. It further provides

generally that when a robust and validated conflict-free supply chain is established or a robust mineral tracing program is developed, we will expect our direct suppliers to procure only minerals using that validated supply chain, so as to avoid the

use of minerals that have financed conflict.

Internal Management Teams

Members of our business, legal, engineering, procurement and sourcing, and information technology functions comprised a core team that was

involved in various phases of compliance with the Rule. Parts of this core team have processes and protocols in place to provide for controls and transparency over the conflict minerals supply chain. The core team formally reports to senior

management on the progress of our compliance efforts throughout the Company and promotes consistency in interpretation of the Rule and industry practice and in implementation of our compliance efforts.

In 2013 we established a steering committee comprised of executive-level representatives of our procurement and sourcing, engineering,

manufacturing and sustaining, and legal functions. The steering committee is responsible for implementing our conflict minerals compliance strategy; setting the general direction of our conflict minerals compliance efforts; and allocating sufficient

resources in the cross-functional core team efforts. Senior management was briefed about the progress of our due diligence efforts on a periodic basis in 2014 and 2015. In addition, members of the core team presented to their respective business

unit Presidents a final, formal review of: (a) their findings as to the source and status of the necessary conflict minerals contained in the covered products sold by their business unit; and (b) their unit’s due diligence efforts.

Control Systems

We have

(a) adopted various processes related to our conflict minerals compliance efforts and determinations; (b) adopted standardized data templates for all business units to ensure consistency across various information technology systems;

(c) improved our electronic repository to retain relevant documentation concerning our conflict minerals compliance efforts and determinations; and (d) adopted written summaries, reviewed by the President of each relevant business unit,

describing how each such business unit complied with the Rule and which of its products were subject to the Rule.

As we do not, except in

very rare instances, have direct relationships with conflict mineral smelters and refiners (“SORs”), we engaged with others in our industry to compare and assess due diligence practices, identify SORs in our supply chains and

formulate potential improvements in our ongoing due diligence efforts. We implemented a supply chain transparency system through the use of due diligence tools developed by the Conflict-Free Sourcing Initiative (“CFSI”), including the

CFSI’s Conflict Minerals Reporting Template (the “Template”), which is designed to identify the SORs that process the conflict minerals in a company’s supply chain. We also support our suppliers’ use of

validation, certification and audit programs on SORs upstream in our supply chain, such as those developed by CFSI; the ITRI Tin Supply Chain Initiative (“iTSCi”); Tungsten Industry – Conflict Mineral Council Framework

(“ti-cmc”); the London Bullion Market Association (“LBMA”); and the Responsible Jewellery Council (“RJC”).

2

We also maintain a company-level grievance mechanism, as described in our Code of Conduct, that

enables employees and others to anonymously report concerns, including any concerns regarding our conflict minerals supply chain. Throughout the year, we communicated this mechanism to our employees through internal webinars on conflict minerals.

Step 2: Identification and Assessment of Supply Chain Risks

In order to identify and assess the risks in our supply chain, we first identified products for sale that we manufactured or contracted to

manufacture in 2014, that contained, or that may contain, necessary conflict minerals. If we determined there was a reasonable possibility that conflict minerals were contained in such products, we considered these products to be within the scope of

the Rule for purposes of gathering further information. We then identified our Tier 1 suppliers from which we purchased parts or components for such products.

As a downstream company typically several tiers removed from mining operations and SORs, we must rely on our suppliers to provide information

regarding the source and presence of necessary conflict minerals in our covered products. To that end, we engaged a third-party data collection and aggregation provider to assist us in conducting due diligence on our supply chain. Information was

collected using the Template, which requested our Tier 1 suppliers to identify the SORs and countries of origin of the necessary conflict minerals contained in our covered products and to determine whether any such necessary conflict minerals came

from recycled or scrap sources. In conducting due diligence, we prioritized responses from certain of our suppliers, as determined based on their strategic importance to us and our annual spend with such suppliers; we communicated this priority to

our third-party data collection and aggregation provider in an effort to increase the response rate of these higher-risk suppliers.

Our

supplier engagement began with introductory emails to relevant Tier 1 suppliers, notifying them that we would be conducting appropriate due diligence regarding the presence, source and chain of custody for any necessary conflict minerals that may be

contained in parts or products that we purchased from them. The emails also described our conflict minerals compliance program and the Rule. In an effort to increase awareness of our conflict minerals program, we provided suppliers with background

materials describing the conflict minerals rule, including frequently asked questions (FAQs) regarding, among other things, conflict minerals tracing. We requested product-level information from our Tier 1 suppliers on the parts and products we

purchased from them. Suppliers were allowed to submit multiple responses as necessary to address all such parts and products. We analyzed all responses to determine their scope. As described further in the “Results of Supply Chain Due

Diligence” section below, in most cases, our Tier 1 suppliers’ responses were at the company level, rather than at the product level.

We pursued subsequent engagement with certain suppliers, which included the following:

| |

• |

|

we sent multiple email reminders requesting survey completion to non-responsive suppliers; |

| |

• |

|

suppliers who remained non-responsive after these email reminders were contacted by phone and offered assistance, including further information about the conflict minerals rule, our conflict minerals program and

clarification regarding how they could provide the required information; and |

| |

• |

|

if, following the above efforts, a supplier still did not provide the information requested, we further escalated the matter internally on a supplier risk priority basis and followed up directly with certain of these

suppliers. |

We reviewed and evaluated all supplier responses for consistency and completeness, both in terms of which

products were said to contain or not contain necessary conflict minerals, as well as the origin of those materials. When necessary, we followed up with suppliers on responses to their reporting templates to seek clarifying or corrective information.

3

In instances where a supplier identified a SOR and the source of its conflict minerals, we sought

to verify this information with third-party databases, internet searches, and reviews of government databases and industry/trade organization lists, including the list of known conflict minerals processing facilities worldwide published by the U.S.

Department of Commerce. We also compared the SORs identified by suppliers in their responses to us against the list of compliant SORs published by CFSI’s Conflict-Free Smelter Program (the “CFSP”), the LBMA and the RJC.

In some cases, a supplier identified a SOR and stated that its conflict minerals were not sourced from any of the covered countries. However, we were sometimes able to confirm, based on available information concerning the SOR identified, that the

SOR was reported to source from one or more of the covered countries. In such cases, we communicated our findings to the supplier for further investigation. As a general matter, we requested that suppliers update their responses to us as more

information became available to them.

Based on our review, we flagged certain responses when:

| |

• |

|

SOR information was provided for a conflict mineral that was not used in the relevant part or product; |

| |

• |

|

SOR information was not provided for a conflict mineral that was used in a relevant part or product; |

| |

• |

|

SOR information provided could not be verified using the methods described above; |

| |

• |

|

a supplier indicated that it sourced conflict minerals from the covered countries, but none of the SORs listed were known to source from the region; |

| |

• |

|

a supplier indicated that it had not received conflict minerals data from all relevant suppliers; |

| |

• |

|

a supplier indicated that it had not identified all of the SORs used to source conflict minerals for the relevant parts and products; |

| |

• |

|

a supplier indicated that it had not provided all applicable SOR information they received from their suppliers; or |

| |

• |

|

a supplier indicated that all of the conflict minerals for the relevant parts and products originated from scrap/recycled sources, but one or more of the SORs listed were not known to be exclusive recyclers.

|

We followed up on all flagged responses to clarify and address inconsistencies, incompleteness, invalid responses,

uncertainties and responses indicating that relevant conflict minerals were or may have been sourced from one or more of the covered countries.

Step 3: Strategy to Respond to Identified Risks

For any SORs that were known to source the relevant conflict minerals from any of the covered countries, we attempted to confirm that such SORs

were listed in the various lists of compliant SORs described above. In addition, a communication was sent to the suppliers listing such SORs, acknowledging the source of the relevant conflict minerals and attaching our Conflict Minerals Policy.

As described in our Conflict Minerals Policy, in the event that we have reason to believe a supplier is supplying us with conflict minerals

from sources that may support conflict in the covered countries, we will encourage that supplier to establish an alternative source of conflict minerals that does not support such conflict, or we may consider reevaluating the supplier relationship.

If a Tier 1 supplier has been unresponsive or otherwise uncooperative in our due diligence efforts, we will also reevaluate that relationship. If a Tier 1 supplier is not compliant with our Conflict Minerals Policy and is unwilling to expect its own

suppliers to use conflict-free sources, we may then also reassess the supplier relationship. As described above, we support the use of validation, certification and audit programs for SORs upstream in our supply chain.

4

Our supplier engagement efforts described above in “Step 2: Identification and Assessment of

Supply Chain Risks” also support our risk mitigation efforts.

Step 4: Independent Third-Party Audit of SORs’ Due Diligence Practices

As stated above, we are a downstream company that is typically several tiers removed from mining operations and SORs, rendering

transparency of our supply chain very difficult. Furthermore, except in rare instances, we do not have direct relationships with SORs and do not perform direct audits of the entities within our supply chain. Accordingly, we rely on our suppliers to

provide the information necessary to assess compliance with our conflict minerals program and support the development and implementation of independent third party audits of SORs’ sourcing, such as the CFSP. We use a third party to aid in

verifying the SOR information and confirm the metals and consider the CFSI, RJC and LBMA valid certifications. In some cases, our third party reaches out directly to SORs as necessary to confirm the information either publicly available or made

available in CMRT responses that may be contradictory or incomplete.

Step 5: Report on Supply Chain Due Diligence

As indicated in the Specialized Disclosure Report on Form SD, this Report is publicly available on the Company’s website at

http://www.slb.com/about/global_citizenship/conflict_minerals.aspx. Our Conflict Minerals Policy also is available at http://www.slb.com/about/global_citizenship/conflict_minerals.aspx.

Results of Supply Chain Due Diligence

We

sent reporting templates to 1,420 suppliers and received completed responses from approximately 43% of these suppliers. As part of our risk identification and mitigation efforts, we focused on obtaining responses from our top suppliers. The

following table lists the response rate and certain other information for our suppliers, based on strategic importance and annual spend.

|

|

|

|

|

| Supplier Rank

(Strategic Importance and Annual Spend) |

|

Response Rate |

|

Number of Suppliers |

| Top |

|

68% |

|

101 |

| High |

|

54% |

|

218 |

| Medium |

|

53% |

|

148 |

| Low |

|

38% |

|

953 |

Most of the respondents indicated that they had not finished the due diligence on their supply chains and

therefore could not complete the reporting template. In addition, although we requested information at the product level, 98% of the surveyed suppliers provided information only at the company level.

For the responses we received at the company level, we do not know whether the SORs listed actually supplied conflict minerals used in the

covered products. Therefore, such SORs are not included in our lists below of the facilities that we know have processed the conflict minerals used in the covered products.

For responses at the product level, based on our due diligence, seven of the verified SORs source conflict minerals from one or more of the

covered countries. Out of these seven SORs and based on our due diligence, six are compliant with the CFSP, and the other facility is progressing toward compliance with the CFSP.

5

The table below lists all of the SORs known to supply necessary conflict minerals contained in

our covered products and that source their conflict minerals from one or more of the covered countries, as of April 30, 2015:

|

|

|

|

|

|

|

| Metal |

|

Smelter/Refiner |

|

Certification Status |

|

Mine Countries of

Origin |

| Tantalum |

|

Hi-Temp Specialty Metals, Inc. |

|

CFSP – Compliant |

|

Brazil, China, Ethiopia, Australia, Bolivia, India, Mozambique, Namibia, Rwanda, Sierra Leone, United States, Zimbabwe |

|

|

|

|

| Tantalum |

|

Kemet Blue Powder |

|

CFSP – Compliant |

|

Burundi, China, DRC- Congo (Kinshasa), Mexico, Mozambique, Niger, Nigeria, Rwanda, United States |

|

|

|

|

| Tin |

|

Malaysia Smelting Corporation (MSC) |

|

CFSP – Compliant |

|

Australia, Bolivia, Brazil, Canada, Chile, China, DRC- Congo (Kinshasa), Indonesia, Japan, Malaysia, Niger, Nigeria, Peru, Portugal, Rwanda, Spain, Switzerland, Thailand |

|

|

|

|

| Tin |

|

Minsur |

|

CFSP – Compliant |

|

Bolivia, Brazil, Canada, China, DRC- Congo (Kinshasa), Indonesia, Malaysia, Peru, Rwanda, Switzerland, Thailand, United States |

|

|

|

|

| Tin |

|

Operaciones Metalurgical S.A. |

|

CFSP – Compliant |

|

Bolivia, Brazil, Canada, China, DRC- Congo (Kinshasa), Indonesia, Japan, Malaysia, Peru, Philippines, Russia, Thailand |

|

|

|

|

| Tin |

|

Yunnan Tin Company Limited |

|

CFSP – Compliant |

|

Angola, Australia, Belgium, Bolivia, Brazil, Canada, China, DRC- Congo (Kinshasa), Ethiopia, Germany, Hong Kong, Indonesia, Malaysia, Peru |

|

|

|

|

| Tungsten |

|

H.C. Starck GmbH |

|

CFSP – Progressing |

|

Australia, Bolivia, Brazil, Canada, China, Estonia, Ethiopia, Germany, India, Japan, Mozambique, Namibia, Peru, Portugal, Russia, Rwanda, Sierra Leone, Spain, Thailand, United States, Zimbabwe |

6

The table below lists all of the SORs known to supply necessary conflict minerals contained in

our covered products and that do not source their conflict minerals from any of the covered countries, as of April 30, 2015:

|

|

|

|

|

|

|

| Metal |

|

Smelter/Refiner |

|

Certification Status |

|

Mine Countries of

Origin |

| Tantalum |

|

Plansee SE Liezen |

|

CFSP – Compliant |

|

Austria |

|

|

|

|

| Gold |

|

Metalor USA Refining Corporation |

|

CFSP – Compliant

LBMA – Compliant

RJC – Compliant |

|

Canada, China, Mexico, Switzerland, United States |

|

|

|

|

| Gold |

|

Royal Canadian Mint |

|

CFSP – Compliant

LBMA – Compliant |

|

Canada, Chile, Germany, Guyana, Japan, Mexico, Peru, Suriname, Switzerland |

|

|

|

|

| Gold |

|

Umicore SA Business Unit Precious Metals Refining |

|

CFSP – Compliant

RJC – Compliant |

|

Unknown |

|

|

|

|

| Gold |

|

United Precious Metal Refining, Inc. |

|

CFSP – Compliant |

|

Australia, Belgium, Canada, China, Russia, Thailand, United States |

Based on the due diligence measures described herein, we have determined that a portion of the necessary

conflict minerals contained in our covered products was supplied by SORs that source conflict minerals from one or more of the covered countries. However, each such SOR is either compliant with a conflict-free sourcing program or is progressing

towards compliance. Thus, we have found no reason to believe that the conflict minerals used in our covered products support conflict in the covered countries.

Future Process Improvements

We intend to

take the following steps to improve our due diligence measures and to further mitigate the risk that necessary conflict minerals contained in our covered products could directly or indirectly finance or benefit armed groups in the covered countries:

covered products and suppliers — review and update the list of covered products and associated Tier 1 suppliers as needed and

standardize internal reporting to improve efficiency and ensure accuracy when identifying both covered products and relevant suppliers;

supplier engagement — continue our supplier engagement process with Tier 1 suppliers to increase supply chain transparency; follow

up with unresponsive suppliers; re-engage suppliers periodically to update changed or new sourcing information; continue to monitor and track suppliers against the expectations set forth in our Conflict Minerals Policy to evaluate their progress in

meeting those expectations; include conflict minerals reviews in relevant supplier business agendas for alignment and progress reviews; seek to incorporate contractual provisions relating to compliance with our Conflict Minerals Policy in relevant

supplier contracts as they are entered into or renewed;

systems support — continue to develop our information systems

with flags and filters reasonably designed to improve our conflict minerals program and obtain further improvements in our third-party data collection and reporting tool; and

educational certification — implement written global procedures for compliance with conflict minerals and provide standard work

instruction and annual required training to employees in legal, engineering, manufacturing, sustaining, procurement and sourcing, sales, finance and compliance functions.

7

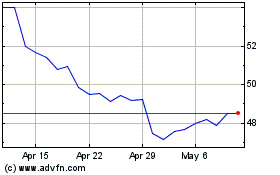

Schlumberger (NYSE:SLB)

Historical Stock Chart

From Mar 2024 to Apr 2024

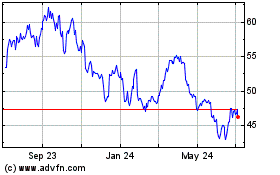

Schlumberger (NYSE:SLB)

Historical Stock Chart

From Apr 2023 to Apr 2024