United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

Masco

Corporation

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| Delaware |

|

1-5794 |

|

38-1794485 |

| (State or other jurisdiction

of incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

|

|

|

| 21001 Van Born Road

Taylor, Michigan |

|

48180 |

| (Address of principal executive offices) |

|

(Zip Code) |

Kenneth G. Cole

Vice President, General Counsel and Secretary

(313) 274-7400

(Name and

telephone number, including area code, of the

person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1. Conflict Minerals Disclosures

Item 1.01. Conflict Minerals Disclosure and Report

As required by the Conflict Minerals Rule, a Conflict Minerals Report is provided as an exhibit to this Form SD and is available on our website at

www.masco.com. We do not incorporate the information contained on our website into this Form SD or our Conflict Minerals Report and such information should not be considered part of this Form SD or the Conflict Minerals Report.

Information concerning Conflict Minerals from recycled or scrap sources that may be contained in our in-scope products is included in the Conflict Minerals

Report and is incorporated in this Form SD by reference.

Item 1.02 Exhibit

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form SD.

Section 2 – Exhibits

Item 2.01

Exhibits

Exhibit 1.01 – Conflict Minerals Report for the calendar year ended December 31, 2014

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

|

|

|

|

|

|

|

|

| MASCO CORPORATION |

|

|

|

|

|

|

|

|

|

| By: |

|

/s/ John G. Sznewajs |

|

|

|

|

|

June 1, 2015 |

| Name: |

|

John G. Sznewajs |

|

|

|

|

|

|

| Title: |

|

Vice President, Treasurer and Chief Financial Officer |

|

|

|

|

|

|

EXHIBIT INDEX

|

|

|

| Exhibit |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report for the calendar year ended December 31, 2014 |

Exhibit 1.01

Conflict Minerals Report

for the year ended December 31, 2014

The date of filing of this Conflict Minerals Report is June 1, 2015

I. Introduction

Unless the context indicates otherwise,

the terms “we,” “its,” “us,” and “our” refer to Masco Corporation and its consolidated subsidiaries. The “Conflict Minerals Rule” means, collectively, Rule 13p-1 under the Securities Exchange Act of

1934, as amended (the “Exchange Act”), and Form SD. As used in this Form SD and consistent with the Conflict Minerals Rule, “Conflict Minerals” are defined as columbite-tantalite (coltan), cassiterite, gold, wolframite and the

derivatives tantalum, tin and tungsten, without regard to their location of origin.

Masco Corporation has included this Conflict Minerals Report for the

year ended December 31, 2014 as an exhibit to its Form SD as required by the Conflict Minerals Rule.

II. Applicability of the Conflict Minerals

Rule to our Business

We manufacture, distribute and install home improvement and building products, with an emphasis on brand-name consumer products

and services holding leadership positions. We are among the largest manufacturers in North America of a number of home improvement and building products, including faucets, cabinets, architectural coatings and windows. We are subject to the Conflict

Minerals Rule because a portion of the products that we manufacture or contract to manufacture contain Conflict Minerals that are necessary to the functionality or production of the products.

We do not directly source Conflict Minerals from mines, smelters or refiners, and we believe that we are, in most cases, many levels removed from, and have

limited influence over, these market participants. Furthermore, because of the depth, breadth and constant evolution of our supply chain and competitive factors affecting our supplier base, there is significant difficulty identifying market

participants upstream from our direct suppliers. However, through the efforts described in this Conflict Minerals Report, and as part of our reasonable country of origin and due diligence processes, we endeavored in good faith to determine if any of

the Conflict Minerals necessary to the functionality or production of the products that we manufactured or contracted to manufacture originated in the Democratic Republic of the Congo (“DRC”) or any adjoining country (as defined in the

Conflict Minerals Rule) and, if so, whether they directly or indirectly financed or benefited an armed group (as defined in the Conflict Minerals Rule) in the DRC or an adjoining country.

III. Our Conflict Minerals Policy

We have adopted and

communicated to our suppliers a Conflict Minerals policy for our company (the “Conflict Minerals Policy”). The Conflict Minerals Policy is part of our Supplier Business Practices Policy. Our Conflict Minerals Policy states our expectations

that our suppliers will source Conflict Minerals from suppliers that meet the requirements of our Supplier Business Practices Policy, implement traceability measures for Conflict Minerals and provide us with all requested information, including

information about all suppliers in their supply chains, so that we can comply with the Conflict Minerals Rule.

1

IV. Reasonable Country of Origin Inquiry Information

As required by the Conflict Minerals Rule, we conducted a “reasonable country of origin inquiry” (“RCOI”) covering 2014. We designed our

RCOI in good faith to determine the origin of Conflict Minerals that are necessary to the functionality or production of products that we manufacture or contract to manufacture.

To identify and assess risk in our supply chain, we determined which of our products and vendors were potentially in-scope for purposes of the Conflict

Minerals Rule through review of product specifications, bills of material, supplier inquiries and other relevant information. We used the Conflict Minerals Reporting Template, developed by the Conflict-Free Sourcing Initiative (“CFSI”), to

identify smelters and refiners in our supply chain, and we requested that our direct suppliers that provided us with components, parts or products containing, or that we believe may have contained, Conflict Minerals, submit information to us by

completing the Conflict Minerals Reporting Template. The information requested included the usage and processing source of Conflict Minerals in each supplier’s materials, as well as information concerning the supplier’s related compliance

efforts.

Pursuant to the Conflict Minerals Rule, based on the results of our RCOI, we were required to conduct due diligence for 2014. Our due diligence

efforts are discussed below.

For our RCOI, to the extent applicable, we utilized the same processes and procedures that we used for conducting our due

diligence.

V. Design of Due Diligence Measures

Design Framework

We designed our due diligence measures

relating to Conflict Minerals to conform, in all material respects, with the criteria set forth in the Organisation for Economic Co-operation and Development’s Due Diligence Guidance for Responsible Supply Chains of Minerals from

Conflict-Affected and High-Risk Areas, including the Supplement on Tin, Tantalum and Tungsten and the Supplement on Gold (Second Edition 2013) (the “OECD Guidance”).

Selected Elements of Design Framework

The OECD Guidance

has established a multi-step framework for due diligence as a basis for responsible global supply chain management of minerals from conflict-affected and high-risk areas. We discuss selected elements of our due diligence program design below.

Our Conflict Minerals Policy, which is incorporated into our Supplier Business Practices Policy, is communicated both internally and externally to our direct

suppliers. In addition, our Supplier Business Practices Policy is publicly available on our website. We have a mechanism for employees, suppliers and other interested parties to report violations of this Policy to us.

We have a team of senior staff responsible for our Conflict Minerals compliance program. In 2014, the team was led by a project manager from our Masco

Business Systems department and included the following functional areas: Health, Safety and Environmental, IT Support, Legal and Supply Chain. Specific personnel at our domestic and international business units, along with a third-party

information management service provider that we retained to complement our internal management processes (the “Service Provider”), communicate with our suppliers regarding our Conflict Minerals Rule compliance. We train these internal

personnel on the Conflict Minerals Rule, the OECD Guidance and our compliance plan.

We furnish our direct suppliers with an overview of the Conflict

Minerals Rule and other training materials. Certain of the overview materials have been translated into local languages. We also furnish our direct suppliers with Conflict Minerals Reporting Templates to gather information about the usage and

processing source of Conflict Minerals in their materials and related compliance efforts.

2

Our Conflict Minerals compliance team communicates with management about supply chain risk assessment. We address

identified risks on a case-by-case basis. This flexible approach enables us to tailor the responses to the risks identified.

We file a Form SD, and to

the extent applicable a Conflict Minerals Report, with the SEC and make them available on our website at www.masco.com.

VI. Due Diligence Program

Execution

We performed the following due diligence measures for the 2014 reporting period.

Our Conflict Minerals team, supported by our Service Provider, sent Conflict Minerals Reporting Templates to our in-scope and potentially in-scope direct

material suppliers. We and the Service Provider then reviewed the completed responses and, where appropriate, followed up with suppliers that did not fully respond to our request or submitted a response that we believed to be inconclusive. To the

extent that a completed response identified a smelter or refiner, we and our Service Provider reviewed this information against the list of compliant smelters and refiners and country of origin information published by the CFSI for its members. To

the extent that a smelter or refiner identified by a direct supplier was not indicated as compliant or the equivalent by an independent third-party, we and our Service Provider consulted publicly available information to attempt to determine whether

that smelter or refiner is known to obtain Conflict Minerals from sources that directly or indirectly finance or benefit armed groups in the DRC or an adjoining country.

Our Conflict Minerals compliance team reported the findings of its supply chain risk assessment to management. We reviewed these findings and developed steps

to improve our due diligence process, as described below under “Steps to Improve Due Diligence.”

In connection with our due diligence, we

utilized the results of the independent third-party audits conducted by the CFSI, the London Bullion Market Association and the Responsible Jewellery Council. We are a member of the CFSI.

VII. Product Information

Notwithstanding our due

diligence efforts, due to the challenges of tracing a multi-tier supply chain, for 2014, we were unable to determine the origin of at least a portion of the Conflict Minerals contained in each of the products that we manufactured or contracted to

manufacture to the extent that the Conflict Minerals were necessary to the functionality or production of the products. The in-scope product categories included the categories described below. However, not all of our products in each of these

categories were in-scope for purposes of our compliance with the Conflict Minerals Rule.

Cabinets and Related Products: Cabinetry for kitchen,

bath, storage, home office and home entertainment applications; kitchen countertops; and an integrated bathroom vanity and countertop solution.

Plumbing Products: Faucet, bathing and showering devices, including faucets, showerheads, handheld showers, valves, bathing units and toilets; tub and

shower systems, bath and shower enclosure units, shower trays and laundry tubs; spas; and brass and copper plumbing system components and other plumbing specialties.

3

Decorative Architectural Products: Hardware for cabinets, doors and windows; and decorative bath hardware

and shower accessories.

Other Specialty Products: Vinyl, fiberglass and aluminum windows and patio doors, windows and doors that combine a wood

interior with a fiberglass exterior; and staple gun tackers, staples and other fastening tools.

For a further discussion of these products, see our

Annual Report on Form 10-K for the year ended December 31, 2014. The information contained in our Form 10-K is not incorporated by reference into this Conflict Minerals Report or our Form SD and should not be considered part of this

Conflict Minerals Report or our Form SD.

We have made efforts to determine the mine or location of origin of the necessary Conflict Minerals contained in

our in-scope products by requesting that our direct suppliers provide us with a completed Conflict Minerals Reporting Template. Where a smelter or refiner was identified, we and/or the Service Provider also reviewed information made available by the

CFSI and publicly available information, in each case to the extent available, to try to determine the mine or location of origin.

The facilities listed

in Appendix A have been identified by our direct suppliers as having processed the necessary Conflict Minerals contained in our products. The facilities listed in Appendix A may not be all of the smelters and refiners in our supply chain, since our

direct suppliers did not identify the facilities that processed some of the necessary Conflict Minerals content contained in our in-scope products, and since we did not receive responses from all of our direct suppliers. In addition, not all of the

included smelters and refiners may have processed the necessary Conflict Minerals contained in our in-scope products, since some suppliers may have reported to us smelters and refiners that were not in our supply chain, due to over-inclusiveness in

the information received from their suppliers or for other reasons.

VIII. Steps to Improve Due Diligence

In addition to the due diligence steps that we took for the 2014 reporting period, which we intend to continue to take for the 2015 reporting period to the

extent applicable, we will endeavor to improve our due diligence for the 2015 reporting period by: continuing to segment our supplier base to direct our focus on those suppliers that we have determined to be in scope for purposes of the Conflict

Mineral Rule; requesting those suppliers that provided company level information for 2014 to provide product level information for 2015; engaging with suppliers that provided incomplete responses or failed to respond to requests, to better ensure

that they provide requested information for 2015; monitoring the progress of traceability measures at suppliers that indicated for 2014 that the source of Conflict Minerals was unknown or undeterminable; and communicating to new suppliers our

sourcing expectations, including by disseminating our Supplier Business Practices Policy to them.

4

Appendix A

Smelter and Refiner and Country of Origin Information

In connection with our reasonable country of origin inquiry and due diligence, as applicable, our suppliers identified to us the smelters and refiners listed

below as having processed the necessary Conflict Minerals contained in our in-scope products in 2014. Our Conflict Minerals Report and the notes that accompany the table contain additional information concerning the information in the table.

Capitalized terms used and not otherwise defined in this Appendix have the meanings indicated in our Conflict Minerals Report.

|

|

|

|

|

| Mineral |

|

Processor |

|

Status |

| Gold |

|

Metalor Technologies SA |

|

Compliant |

| Tantalum |

|

Guangdong Zhiyuan New Material Co., Ltd. |

|

Compliant |

| Tin |

|

CV United Smelting |

|

Compliant |

| Tin |

|

EM Vinto |

|

Compliant |

| Tin |

|

Malaysia Smelting Corporation (MSC) |

|

Compliant |

| Tin |

|

Mineração Taboca S.A. |

|

Compliant |

| Tin |

|

Minsur |

|

Compliant |

| Tin |

|

Operaciones Metalurgical S.A. |

|

Compliant |

| Tin |

|

PT Babel Inti Perkasa |

|

Compliant |

| Tin |

|

PT Bangka Putra Karya |

|

Compliant |

| Tin |

|

PT Bukit Timah |

|

Compliant |

| Tin |

|

PT Eunindo Usaha Mandiri |

|

Compliant |

| Tin |

|

PT Inti Stania Prima |

|

Compliant |

| Tin |

|

PT Mitra Stania Prima |

|

Compliant |

| Tin |

|

PT Refined Bangka Tin |

|

Compliant |

| Tin |

|

PT Sariwiguna Binasentosa |

|

Compliant |

| Tin |

|

PT Timah (Persero) Tbk Kundur |

|

Compliant |

| Tin |

|

PT Tinindo Inter Nusa |

|

Compliant |

| Tin |

|

Thaisarco |

|

Compliant |

| Tin |

|

Yunnan Tin Group (Holding) Company Limited |

|

Compliant |

| Tin |

|

China Tin Group Co., Ltd. |

|

Active |

| Tin |

|

PT Bangka Kudai Tin |

|

Known |

| Tin |

|

PT Bangka Timah Utama Sejahtera |

|

Known |

| Tin |

|

PT Karimun Mining |

|

Known |

We note the following in connection with the information in the table:

| |

(a) |

All information in the table is as of May 27, 2015. |

| |

(b) |

“Compliant” means that the smelter or refiner was compliant with the CFSI’s Conflict-Free Smelter Program’s (“CFSP”) assessment protocols including through mutual recognition, or was

indicated as “Re-audit in process.” Included smelters or refiners were not necessarily Compliant for all or part of 2014 and may not continue to be Compliant for any future period. |

A-1

| |

(c) |

“Active” means that the smelter or refiner is listed by the CFSI as having submitted a signed Agreement for the Exchange of Confidential Information and Auditee Agreement contracts to the CFSP or, according to

information published by the CFSI, the smelter has agreed to complete a CFSP validation audit within two years of membership issuance by the Tungsten Industry – Conflict Minerals Council. |

| |

(d) |

“Known” means the smelter or refiner is not listed as “Compliant” or “Active.” |

| |

(e) |

The compliance status reflected in the table is based solely on information made publicly available by the CFSI. |

Country of Origin Information

The countries of origin of

the Conflict Minerals processed by the Compliant smelters and refiners listed above may have included countries in each of the categories listed below. Our country of origin determinations were based on information made available by the CFSI to its

members.

L1 – Countries that are not identified as conflict regions or plausible areas of smuggling or export of from these regions of Conflict

Minerals: Argentina, Australia, Austria, Belgium, Bolivia, Brazil, Canada, Chile, China, Colombia, Cote d’Ivoire, Czech Republic, Djibouti, Egypt, Estonia, Ethiopia, France, Germany, Guyana, Hungary, India, Indonesia, Ireland, Israel, Japan,

Kazakhstan, Laos, Luxembourg, Madagascar, Malaysia, Mongolia, Myanmar, Namibia, Netherlands, Nigeria, Peru, Portugal, Russia, Sierra Leone, Singapore, Slovakia, South Korea, Spain, Suriname, Switzerland, Taiwan, Thailand, United Kingdom, United

States, Vietnam and Zimbabwe.

L2 – Countries that are known or plausible countries for smuggling, export out of region or transit of materials

containing Conflict Minerals: Kenya, Mozambique and South Africa.

L3 – The DRC and its nine adjoining countries: Angola, Burundi, Central

African Republic, Republic of Congo, Rwanda, South Sudan, Uganda, United Republic of Tanzania and Zambia.

DRC – The Democratic Republic of the

Congo.

In addition, some of the listed Compliant smelters and refiners may have processed Conflict Minerals originating from recycled or scrap sources.

For 2014, we were not able to determine the country of origin of the Conflict Minerals processed by any of the smelters or refiners listed as

“Active” or “Other.”

A-2

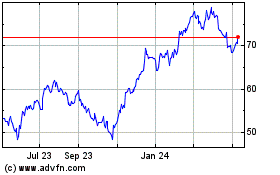

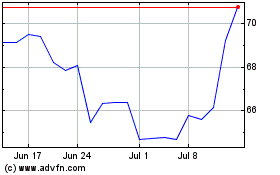

Masco (NYSE:MAS)

Historical Stock Chart

From Mar 2024 to Apr 2024

Masco (NYSE:MAS)

Historical Stock Chart

From Apr 2023 to Apr 2024