UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

GREATBATCH, INC.

(Exact name of registrant as specified in its charter)

|

| | | | |

Delaware | | 1-16137 | | 16-1531026 |

(State or other jurisdiction of incorporation or organization)

| | (Commission File Number) | | (I.R.S Employer Identification No.) |

2595 Dallas Parkway

Suite 310

Frisco, Texas 75034

(Address of principal executive offices)

(716) 759-5600

(Name and telephone number, including area code,

of the person to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

x Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014.

Introduction

Greatbatch, Inc. (the “Company” or “Greatbatch”) has two reportable segments: Greatbatch Medical and QiG Group (“QiG”). Greatbatch Medical designs and manufactures medical devices and components for the cardiac, neuromodulation, orthopaedic, portable medical, vascular and energy markets among others. The Greatbatch Medical segment also offers assembly and design engineering services for medical devices that utilize its component products. The segment’s products include: batteries, capacitors, EMI filters, feedthroughs, coated electrodes, precision components, enclosures, value-added assemblies, stimulation leads, introducers, steerable sheaths, specialty catheter shaft components, cases and trays, implants, instruments, primary cells, and primary and secondary battery packs.

QiG focuses on developing medical device systems for some of healthcare’s most pressing challenges. QiG’s products include neural interface thin-film electrodes for neuromodulation leads, sub-systems and components, which are used in the neuroscience and clinical markets as well as the Algovita Spinal Cord Stimulation system, which is a neurostimulation product of QiG’s Algostim, LLC subsidiary. On August 12, 2014, the Company acquired Centro de Construcción de Cardioestimuladores del Uruguay (“CCC”), which develops and manufactures active implantable neuromodulation medical device systems that produces a range of medical devices including implantable pulse generators, programmer systems, battery chargers, patient wands and leads. CCC’s products are excluded from the scope of this report for the 2014 reporting period.

This report has been prepared pursuant to Rule 13p-1 under the Securities and Exchange Act of 1934, as amended, for the reporting period from January 1, 2014 to December 31, 2014. This rule requires all public companies that manufacture, or contract to manufacture, products to annually disclose whether columbite-tantalite (coltan), cassiterite, wolframite, including their derivatives, which are limited to tantalum, tin, tungsten, or gold (“3TG”) (“Necessary Conflict Minerals”) are necessary to the functionality or production of these products and whether the Necessary Conflict Minerals originated in the Democratic Republic of the Congo or an adjoining country (the “Covered Countries”). For the majority of products discussed above, the performance requirements imposed by the markets we serve often require the use of Necessary Conflict Minerals.

Greatbatch’s policy with respect to the sourcing of conflict minerals can be found at www.greatbatch.com under the “Investor Relations” drop down menu and clicking on “Governance.”

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

Greatbatch has concluded in good faith that during the 2014 calendar year:

| |

(i) | Greatbatch has manufactured and contracted to manufacture products containing 3TG and have determined that the use of these minerals is necessary to the functionality or production of these products. |

| |

(ii) | Based on the “reasonable country of origin inquiry” (“RCOI”) conducted, Greatbatch does not have reason to believe that the Necessary Conflict Minerals used within our introducers and steerable sheaths product lines originated in the Covered Countries. All suppliers of the Necessary Conflict Minerals used in these product lines certified to the Company that the material was sourced outside the Covered Countries. Additionally, the Company confirmed that the smelters utilized by these suppliers received a “conflict free” designation from the Conflict Free Smelter Program (“CFSP”) developed by the Electronic Industry Citizenship Coalition (“EICC”) and the Global e-Sustainability Initiative (“GeSI”). |

| |

(iii) | For the remainder of our product lines that utilize Necessary Conflict Minerals, based on the RCOI conducted, we were unable to obtain 100% confirmation from the direct suppliers for those product lines as to the location or source of the 3TG or component parts containing 3TG that were sold to Greatbatch. Therefore, the Company conducted due diligence activities for the remaining product lines and details these activities in the attached Conflict Minerals Report. |

As part of the RCOI procedures performed, we established a cross-functional conflict minerals steering committee comprised of representatives from the Company’s Supply Chain and Operational Excellence Group, Corporate Compliance Office, and Finance Department, which was overseen by our Executive Vice President and Chief Financial Officer. The Supply Chain and Operational Excellence Group was responsible for performing a review of the Company’s products, conducting the country of origin inquiry, and performing the due diligence review. The Corporate Compliance Office and Finance Department were responsible for reporting and general oversight. The conflict minerals steering committee also provided updates to the Company’s Audit Committee with regards to the measures undertaken by management.

Greatbatch’s RCOI consisted of surveying suppliers that directly supply 3TG, or component parts containing 3TG, to Greatbatch (“Tier 1 Suppliers”). An assessment process was undertaken

by the Company to identify the Tier 1 Suppliers that supplied 3TG, or component parts containing 3TG, to Greatbatch between January 1, 2014 and December 31, 2014, which included a review of the bills of material for each of our products. Based upon this assessment, our supplier survey list was established. Tier 1 Suppliers of 3TG or component parts that contained or potentially contained 3TG were included in our supplier survey list.

As a first step to engaging with our supply chain, the Company sent a notification to relevant Tier 1 Suppliers during 2014 informing them about the conflict minerals rule and asking them to complete the conflict minerals survey based on the standard template designed by the EICC and GeSI known as the Conflict Minerals Reporting Template. Given the annual compliance requirements, and in an attempt to improve future supplier response rates, the Company is in the process of implementing terms for new or renewed contracts requiring suppliers to respond to inquiries regarding Necessary Conflict Minerals in a timely manner and expect this to be effective during the 2015 calendar year.

The Company reviewed responses received from suppliers for inconsistencies, completeness, and inaccuracies. Responses that failed this review were identified for additional follow up. Non-responsive suppliers were reminded to respond to the survey within a given time period. The Company re-engaged all suppliers that did not send credible representations through further notifications. In total, the Company sent 277 surveys to suppliers and received 222 completed responses, representing an 80% response rate. This compares favorably to our 52% response rate in 2013.

In accordance with Rule 13p-1, Greatbatch has filed this Specialized Disclosure Form and the associated Conflict Minerals Report for the calendar year ended December 31, 2014 filed herewith as Exhibit 1.01. Both of these reports are available on the Company’s website at www.greatbatch.com under the “Investor Relations” drop down menu and clicking on “SEC Filings.”

Item 1.02 Exhibit

A copy of Greatbatch’s Conflict Minerals Report is filed as Exhibit 1.01 to this Form SD.

Section 2 – Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this report:

Exhibit 1.01 – Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD.

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the Registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

|

| |

Dated: May 28, 2015 | GREATBATCH, INC. By: /s/ Michael Dinkins

Michael Dinkins

Executive Vice President and Chief Financial Officer |

Exhibit 1.01

Greatbatch, Inc.

Conflict Minerals Report

For the Year Ended December 31, 2014

Section 1: Company overview – Unaudited

This is the Conflict Minerals Report of Greatbatch, Inc. (“Greatbatch,” “the Company,” “we,” or “our”) for the calendar year ended December 31, 2014 in accordance with Rule 13p-1 under the Securities and Exchange Act of 1934 (“Rule 13p-1”).

Rule 13p-1 requires all public companies that manufacture, or contract to manufacture, products to annually disclose whether columbite-tantalite (coltan), cassiterite, wolframite, including their derivatives, which is limited to tantalum, tin, tungsten, or gold (“3TG”) (“Necessary Conflict Minerals”) are necessary to the functionality or production of these products and whether the Necessary Conflict Minerals originated in the Democratic Republic of the Congo or an adjoining country (the “Covered Countries”). For the majority of products discussed below, the performance requirements imposed by the markets we serve often require the use of Necessary Conflict Minerals.

The Company established a conflict minerals policy to establish and document the formal Statement of Policy of the Company regarding the conflict minerals requirements set forth in Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010 (“Section 1502”) and Rule 13p-1. It is the policy of the Company that it will comply fully with all applicable provisions of Section 1502 and Rule 13p-1. This policy can be found at www.greatbatch.com under the “Investor Relations” drop down menu and clicking on “Governance.”

Greatbatch has concluded that during the 2014 calendar year it has manufactured and contracted to manufacture products containing 3TG and that the use of these minerals is necessary to the functionality or production of those products identified in Section 6 of this Conflict Minerals Report (the “Covered Products”).

As part of the reasonable country of origin inquiry (“RCOI”) procedures performed on the Necessary Conflict Minerals for the Covered Products, we established a cross-functional conflict minerals steering committee comprised of representatives from the Company’s Supply Chain and Operational Excellence Group, Corporate Compliance Office, and Finance Department, which was overseen by our Executive Vice President and Chief Financial Officer. The Supply Chain and Operational Excellence Group was responsible for performing a review of the Covered Products, conducting the country of origin inquiry, and performing the due diligence review. The Corporate Compliance Office and Finance Department were responsible for reporting and general oversight. The conflict minerals steering committee also provided updates to the Company’s Audit Committee with regards to the measures undertaken by management.

Greatbatch’s RCOI consisted of surveying suppliers that directly supply 3TG, or component parts containing 3TG, to Greatbatch (“Tier 1 Suppliers”). An assessment process was undertaken by the Company to identify the Tier 1 Suppliers that supplied 3TG, or component parts containing 3TG, to

Greatbatch between January 1, 2014 and December 31, 2014, which included a review of the bills of material for each of our Covered Products. Based upon this assessment, our supplier survey list was established. Tier 1 Suppliers of 3TG or component parts that contained or potentially contained 3TG were included in our supplier survey list.

As a first step to engaging with our supply chain, the Company sent a notification to relevant Tier 1 Suppliers during 2014 informing them about the conflict minerals rule and asking them to complete the conflict minerals survey based on the standard template designed by the Electronics Industry Citizenship Coalition/Global e-Sustainability Initiative (“EICC/GeSI”) known as the Conflict Minerals Reporting Template. Given the annual compliance requirements, and in an attempt to improve future supplier response rates, the Company is in the process of implementing terms for new or renewed contracts requiring suppliers to respond to inquiries regarding Necessary Conflict Minerals in a timely manner and expect this to be effective during the 2015 calendar year.

The Company surveyed 277 Tier 1 Suppliers identified during the applicability assessment that may supply the Company with 3TG or component parts containing 3TG. Based upon our internal applicability assessment, it was determined that our EMI filters, stimulation leads, and specialty catheter shaft component products do not contain any 3TG minerals. Every survey received was reviewed and based upon the response, and in accordance with Rule 13p-1, the Company undertook further due diligence efforts with regards to Covered Products to determine whether the 3TG in those Covered Products originated in the Covered Countries from sources that directly or indirectly finance or benefit armed groups in the Covered Countries. These due diligence efforts are described below.

Section 2: Due diligence framework – Unaudited

The Company designed its due diligence measures to be in conformity with the internationally recognized due diligence framework as set forth in the Organization for Economic Cooperation and Development (“OECD”) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD, 2013) and related supplements for 3TG (“OECD Framework”).

Section 3: Due diligence measures undertaken - Unaudited

The Company’s due diligence efforts for the calendar year ended December 31, 2014 included the following:

| |

• | The Company surveyed 277 of its Tier 1 Suppliers and received 222 completed responses, representing an 80% response rate. This compares favorably to our 52% response rate in 2013. We evaluated the survey responses for consistency of data provided; including whether those responses were complete and to identify any contradictions or inconsistencies found in those responses. |

| |

• | For those suppliers who provided smelter or refiner information for applicable 3TG minerals, the Company began analyzing those smelters to determine if they were in fact smelters, if that smelter was part of the Company’s supply chain and began comparing those smelters to the list of facilities |

which have received a “conflict free” designation from the Conflict Free Smelter Program (“CFSP”) developed by the EICC/GeSI or other independent third party audit programs. Based upon the information provided by Greatbatch’s suppliers and its own due diligence efforts, the Company was not able to conclusively determine the countries of origin of the Necessary Conflict Minerals included in the Covered Products listed in Section 6 as not all supplier surveys were returned, the responses received were incomplete or not conclusive, and/or the smelter or refiner information provided by the suppliers reflected all smelters or refiners that the supplier has conducted business with at some point during the year. As a result, the Company was unable to specifically identify those smelters or refiners that were related to Greatbatch’s supply chain for the 2014 calendar year.

| |

• | The smelter and refiner information provided at Annex I includes only those smelters and refiners provided by our suppliers that the Company was able to verify to the CFSP or the U.S. Department of Commerce Reporting Requirements under Section 1502(d)(3)(C) of the Dodd-Frank Act World-Wide Conflict Mineral Processing Facilities lists. The information listed does not include all the smelters or refiners provided by our suppliers as the list was modified to remove unknown or duplicate smelters and refiners. |

| |

• | A conflict minerals reporting database was developed and updated to summarize the results of the risk assessment process and keep management informed of the status of the conflict minerals compliance process. |

| |

• | The Company’s supply chain for our Covered Products is complex, and there are many third parties in the supply chain between our direct supplier and the original sources of the Necessary Conflict Minerals. In this regard, we do not purchase Necessary Conflict Minerals directly from mines, smelters or refiners. We must therefore rely on our suppliers to provide information regarding the origin of the Necessary Conflict Minerals that are included in our Covered Products. Additionally, we believe that the smelters and refiners of the Necessary Conflict Minerals are best suited to identify the sources of the Necessary Conflict Minerals. As a result, our due diligence efforts relied on the CFSP and our direct suppliers. |

Section 4: Independent private sector audit

Pursuant to Rule 13p-1, for the 2014 calendar year, Greatbatch is not required and did not voluntarily obtain an independent private sector audit of the Conflict Minerals Report.

Section 5: Continuous improvement efforts to mitigate risk – Unaudited

Greatbatch intends to take the following steps to improve the number and quality of supplier responses in the next compliance period and to mitigate risk that the Necessary Conflict Minerals used in our products may directly or indirectly finance or benefit armed groups in the Covered Countries:

| |

• | Work with suppliers who did not respond to the Company’s 2014 survey to help them understand the importance of this initiative to Greatbatch and to encourage their participation in 2015. |

| |

• | Enhance our smelter and refiner review process as well as work with suppliers to re-validate, improve, and refine their reported information. |

| |

• | Implement new terms and conditions requiring suppliers to respond to inquiries regarding Necessary Conflict Minerals in a timely manner within our contract language for new or renewed contracts entered into during 2015. |

| |

• | Continue to encourage suppliers of 3TG or whose products contain 3TG to establish policies, due diligence frameworks, and management systems consistent with the OECD Framework. To do this, Greatbatch will investigate changes to existing suppliers’ agreements and review all new suppliers’ Conflict Minerals Policy statements. |

| |

• | Build on our supplier survey procedures, to ensure that surveys are requested from manufacturers as opposed to distributors to improve on the quality of information obtained. |

| |

• | Evaluate external information technology providers to assist us with our due diligence process and identifying the source of 3TG utilized in our Covered Products. |

Section 6: List of Covered Products – Unaudited

Below is a listing of products that were determined by the Company to include 3TG that are necessary to the functionality or production of our products and were subject to our due diligence procedures. Based on the Company’s due diligence efforts to date, the Company does not have sufficient information to determine the mines and the country of origin of the conflict minerals in its Covered Products or the facilities used to process the conflict minerals, including whether the conflict minerals were from recycled or scrap sources. A description of the Company’s efforts to determine the mine(s) or location of origin are included in the due diligence measures described above. The smelters and refiners included in our suppliers’ responses that we were able to reasonably identify as an operational smelter and refiner are included in Annex I below. This list has been modified to remove unknown or duplicate smelters and refiners.

|

| | |

Product | Description | 3TG Included |

Batteries | Lithium iodine Lithium silver vanadium oxide Lithium carbon monoflouride Lithium ion rechargeable Lithium SVO/CFx

| Tin, Gold |

Capacitors | Storage for energy generated by a battery before delivery to the heart. Used in ICDs and CRT-Ds. | Tantalum |

Feedthroughs | Allow electrical signals to be brought from inside hermetically sealed implantable medical devices to an electrode | Tin, Gold, Tungsten |

Coated electrodes | Deliver electric signal from the feedthrough to a body part undergoing stimulation | Tin, Gold |

Precision components | Machined Molded and over molded products | Tin, Gold |

Enclosures | Titanium Stainless steel | Tantalum, Tin, Tungsten, Gold

|

Value-added assemblies | Combination of multiple components in a single package/unit | Tantalum, Tin, Tungsten, Gold |

Cases and trays | Delivery systems for cleaning and sterilizing orthopaedic instruments and implants | Tantalum, Tin |

Implants | Orthopaedic implants for large joint, spine, extremity and trauma procedures | Tantalum, Tin, Tungsten, Gold |

Instruments | Reusable and single use orthopaedic instruments for large joint, spine, extremity and trauma procedures | Tantalum, Tin, Tungsten |

Primary cells | Low-rate Moderate-rate High rate (spiral) Wide Range | Tantalum, Tin, Tungsten, Gold |

Primary and secondary battery packs | Highly-customized pack solutions | Tantalum, Tin, Tungsten, Gold |

QiG thin-filmed electrodes | High-resolution, microscale neural recording and/or stimulation arrays manufactured using techniques from semiconductor and MEMS industries

| Gold |

Algovita Spinal Cord Stimulation system | Spinal cord stimulation system to treat chronic intractable pain of the trunk and/or limbs

| Tantalum, Tin, Tungsten, Gold |

ANNEX I

|

| | |

Subject Mineral | Smelter or Refiner Name | Country location of Smelter or Refiner |

Gold | Perth Mint | AUSTRALIA |

Gold | Umicore SA Business Unit Precious Metals Refining | BELGIUM |

Gold | EM Vinto | BOLIVIA |

Gold | AngloGold Ashanti Córrego do Sítio Minerção | BRAZIL |

Gold | Umicore Brasil Ltda | BRAZIL |

Gold | CCR Refinery – Glencore Canada Corporation | CANADA |

Gold | Johnson Matthey Ltd | CANADA |

Gold | Royal Canadian Mint | CANADA |

Gold | Codelco | CHILE |

Gold | China National Gold Group Corporation | CHINA |

Gold | Daye Non-Ferrous Metals Mining Ltd. | CHINA |

Gold | Gansu Seemine Material Hi-Tech Co Ltd | CHINA |

Gold | Guangdong Jinding Gold Limited | CHINA |

Gold | Hunan Chenzhou Mining Group Co., Ltd. | CHINA |

Gold | Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited | CHINA |

Gold | Jiangxi Copper Company Limited | CHINA |

Gold | Lingbao Gold Company Limited | CHINA |

Gold | Lingbao Jinyuan Tonghui Refinery Co. Ltd. | CHINA |

Gold | Luoyang Zijin Yinhui Metal Smelt Co Ltd | CHINA |

Gold | Metalor Technologies (Suzhou) Ltd. | CHINA |

Gold | Penglai Penggang Gold Industry Co Ltd | CHINA |

Gold | Shandong Zhaojin Gold & Silver Refinery Co. Ltd | CHINA |

Gold | Suzhou Xingrui Noble | CHINA |

Gold | The Great Wall Gold and Silver Refinery of China | CHINA |

Gold | The Refinery of Shandong Gold Mining Co. Ltd | CHINA |

Gold | TongLing Nonferrous Metals Group Holdings Co;Ltd | CHINA |

Gold | Yantai Guodasafina High-Tech Environmental Refinery Co. Ltd. | CHINA |

|

| | |

Gold | Yunnan Copper Industry Co Ltd | CHINA |

Gold | Zhongyuan Gold Smelter of Zhongjin Gold Corporation | CHINA |

Gold | Zijin Mining Group Co. Ltd | CHINA |

Gold | Allgemeine Gold-und Silberscheideanstalt A.G. | GERMANY |

Gold | Aurubis AG | GERMANY |

Gold | Bauer Walser AG | GERMANY |

Gold | C. Hafner GmbH + Co. KG | GERMANY |

Gold | Doduco | GERMANY |

Gold | Heimerle + Meule GmbH | GERMANY |

Gold | Heraeus Precious Metals GmbH & Co. KG | GERMANY |

Gold | Heraeus Ltd. Hong Kong | HONG KONG |

Gold | Metalor Technologies (Hong Kong) Ltd | HONG KONG |

Gold | PT Aneka Tambang (Persero) Tbk | INDONESIA |

Gold | Chimet S.p.A. | ITALY |

Gold | Aida Chemical Industries Co. Ltd. | JAPAN |

Gold | Asahi Pretec Corporation | JAPAN |

Gold | Asaka Riken Co Ltd | JAPAN |

Gold | Chugai Mining | JAPAN |

Gold | Dowa | JAPAN |

Gold | Eco-System Recycling Co., Ltd. | JAPAN |

Gold | Ishifuku Metal Industry Co., Ltd. | JAPAN |

Gold | Japan Mint | JAPAN |

Gold | JX Nippon Mining & Metals Co., Ltd | JAPAN |

Gold | Kojima Chemicals Co. Ltd | JAPAN |

Gold | Kosaka Seiren | JAPAN |

Gold | Matsuda Sangyo Co., Ltd. | JAPAN |

Gold | Mitsubishi Materials Corporation | JAPAN |

Gold | Mitsui Mining and Smelting Co., Ltd. | JAPAN |

Gold | Nihon Material Co. LTD | JAPAN |

|

| | |

Gold | Ohura Precious Metal Industry Co., Ltd | JAPAN |

Gold | Pan Pacific Copper Co. LTD | JAPAN |

Gold | Sumitomo Metal Mining Co. Ltd. | JAPAN |

Gold | Tanaka Kikinzoku Kogyo K.K. | JAPAN |

Gold | Tokuriki Honten Co. Ltd | JAPAN |

Gold | Yamamoto Precious Metal Co., Ltd. | JAPAN |

Gold | Yokohama Metal Co Ltd | JAPAN |

Gold | Kazzinc Ltd | KAZAKHSTAN |

Gold | Daejin Indus | KOREA, REPUBLIC OF |

Gold | DaeryongENC | KOREA, REPUBLIC OF |

Gold | Do Sung Corporation | KOREA, REPUBLIC OF |

Gold | Hwasung CJ Co. Ltd | KOREA, REPUBLIC OF |

Gold | Korea Metal Co. Ltd | KOREA, REPUBLIC OF |

Gold | LG-Nikko | KOREA, REPUBLIC OF |

Gold | Samduck Precious Metals | KOREA, REPUBLIC OF |

Gold | SAMWON METALS Corp. | KOREA, REPUBLIC OF |

Gold | Torecom | KOREA, REPUBLIC OF |

Gold | Kyrgyzaltyn JSC | KYRGYZSTAN |

Gold | Caridad | MEXICO |

Gold | Met-Mex Peñoles, S.A. | MEXICO |

Gold | Schone Edelmetaal | NETHERLANDS |

Gold | Bangko Sentral ng Pilipinas (Central Bank of the Philippines) | PHILIPPINES |

Gold | FSE Novosibirsk Refinery | RUSSIAN FEDERATION |

Gold | JSC Ekaterinburg Non-Ferrous Metal Processing Plant | RUSSIAN FEDERATION |

Gold | JSC Uralectromed | RUSSIAN FEDERATION |

Gold | Moscow Special Alloys Processing Plant | RUSSIAN FEDERATION |

Gold | OJSC “The Gulidov Krasnoyarsk Non-Ferrous Metals Plant” (OJSC Krastvetmet) | RUSSIAN FEDERATION |

Gold | OJSC Kolyma Refinery | RUSSIAN FEDERATION |

Gold | OJSC Novosibirsk | RUSSIAN FEDERATION |

|

| | |

Gold | Prioksky Plant of Non-Ferrous Metals | RUSSIAN FEDERATION |

Gold | SOE Shyolkovsky Factory of Secondary Precious Metals | RUSSIAN FEDERATION |

Gold | L’ azurde Company For Jewelry | SAUDI ARABIA |

Gold | Metalor Technologies (Singapore) Pte. Ltd. | SINGAPORE |

Gold | Rand Refinery (Pty) Ltd | SOUTH AFRICA |

Gold | SEMPSA Joyería Platería SA | SPAIN |

Gold | Boliden AB | SWEDEN |

Gold | Argor-Heraeus SA | SWITZERLAND |

Gold | Cendres & Métaux SA | SWITZERLAND |

Gold | Metalor Technologies SA | SWITZERLAND |

Gold | PAMP SA | SWITZERLAND |

Gold | PX Précinox SA | SWITZERLAND |

Gold | Valcambi SA | SWITZERLAND |

Gold | Solar Applied Materials Technology Corp. | TAIWAN |

Gold | Umicore Precious Metals Thailand | THAILAND |

Gold | Atasay Kuyumculuk Sanayi Ve Ticaret A.S. | TURKEY |

Gold | Istanbul Gold Refinery | TURKEY |

Gold | Nadir Metal Rafineri San. Ve Tic. A.Ş. | TURKEY |

Gold | Colt Refining | UNITED STATES |

Gold | Heraeus Precious Metals | UNITED STATES |

Gold | Johnson Matthey Inc | UNITED STATES |

Gold | Kennecott Utah Copper | UNITED STATES |

Gold | Materion | UNITED STATES |

Gold | Metalor USA Refining Corporation | UNITED STATES |

Gold | Ohio Precious Metals, LLC | UNITED STATES |

Gold | Sabin Metal Corp. | UNITED STATES |

Gold | So Accurate Group, Inc. | UNITED STATES |

Gold | United Precious Metal Refining, Inc. | UNITED STATES |

Gold | Almalyk Mining and Metallurgical Complex (AMMC) | UZBEKISTAN |

|

| | |

Gold | Navoi Mining and Metallurgical Combinat | UZBEKISTAN |

Tantalum | Plansee | AUSTRIA |

Tantalum | LSM Brasil S.A. | BRAZIL |

Tantalum | Mineração Taboca S.A | BRAZIL |

Tantalum | Changsha South Tantalum Niobium Co., Ltd. | CHINA |

Tantalum | Conghua Tantalum and Niobium Smeltry | CHINA |

Tantalum | Duoluoshan | CHINA |

Tantalum | F&X Electro-Materials Ltd. | CHINA |

Tantalum | Guangdong Zhiyuan New Material Co., Ltd. | CHINA |

Tantalum | Hengyang King Xing Lifeng New Materials Co., Ltd. | CHINA |

Tantalum | Jiangxi Rare Earth Metals Tungsten Group Corp. | CHINA |

Tantalum | JiuJiang JinXin Nonferrous Metals Co. Ltd. | CHINA |

Tantalum | Jiujiang Tanbre Co.,Ltd | CHINA |

Tantalum | King-Tan Tantalum Industry Ltd | CHINA |

Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. | CHINA |

Tantalum | RFH Tantalum Smeltry Co., Ltd | CHINA |

Tantalum | Shanghai Jiangxi Metals Co. Ltd | CHINA |

Tantalum | Yichun Jin Yang Rare Metal Co., Ltd | CHINA |

Tantalum | Zhuzhou Cement Carbide | CHINA |

Tantalum | Molycorp Silmet A.S. | ESTONIA |

Tantalum | H.C. Starck GmbH Goslar | GERMANY |

Tantalum | H.C. Starck GmbH Laufenburg | GERMANY |

Tantalum | H.C. Starck Hermsdorf GmbH | GERMANY |

Tantalum | H.C. Starck Smelting GmbH & Co.KG | GERMANY |

Tantalum | Metallurgical Products India Pvt. Ltd. | INDIA |

Tantalum | H.C. Starck Ltd. | JAPAN |

Tantalum | Mitsui Mining & Smelting | JAPAN |

Tantalum | Taki Chemical Co., Ltd. | JAPAN |

Tantalum | Ulba | KAZAKHSTAN |

|

| | |

Tantalum | KEMET Blue Metals | MEXICO |

Tantalum | Solikamsk Metal Works | RUSSIAN FEDERATION |

Tantalum | Tantalite Resources | SOUTH AFRICA |

Tantalum | H.C. Starck Co., Ltd. | THAILAND |

Tantalum | Cabot Corporation | UNITED STATES |

Tantalum | Exotech Inc. | UNITED STATES |

Tantalum | Gannon & Scott | UNITED STATES |

Tantalum | Global Advanced Metals | UNITED STATES |

Tantalum | H.C. Starck Inc. | UNITED STATES |

Tantalum | Hi-Temp | UNITED STATES |

Tantalum | Kemet Blue Powder | UNITED STATES |

Tantalum | QuantumClean | UNITED STATES |

Tantalum | Telex | UNITED STATES |

Tin | Jean Goldcchmidt International SA | BELGIUM |

Tin | Metallo Chimique | BELGIUM |

Tin | N.V. Umicore SA | BELGIUM |

Tin | EM Vinto | BOLIVIA |

Tin | OMSA | BOLIVIA |

Tin | SGS BOLIVIA S.A. | BOLIVIA |

Tin | Cooper Santa | BRAZIL |

Tin | Estanho de Rondônia S.A. | BRAZIL |

Tin | Magnu’s Minerais Metais e Ligas LTDA | BRAZIL |

Tin | Melt Metais e Ligas S/A | BRAZIL |

Tin | Mineração Taboca S.A. | BRAZIL |

Tin | Soft Metais, Ltda. | BRAZIL |

Tin | White Solder Metalurgia | BRAZIL |

Tin | China Rare Metal Materials Company | CHINA |

Tin | China Tin Group Co., Ltd. | CHINA |

Tin | CNMC (Guangxi) PGMA Co. Ltd. | CHINA |

|

| | |

Tin | Gejiu Kai Meng Industry and Trade LLC | CHINA |

Tin | Gejiu Non-Ferrous Metal Processing Co. Ltd. | CHINA |

Tin | Gejiu Zi-Li | CHINA |

Tin | Gold Bell Group | CHINA |

Tin | Guihuacheng - Guangxi Pinggui PGMA Co. Ltd. | CHINA |

Tin | HongQiao Co., Ltd. | CHINA |

Tin | Huichang Jinshunda Tin Co. Ltd | CHINA |

Tin | Jiangxi Nanshan | CHINA |

Tin | Laibin China Tin Smelting Co., Ltd. | CHINA |

Tin | Linwu Xianggui Smelter Co | CHINA |

Tin | Liuzhou China Tin | CHINA |

Tin | Minmetals Ganzhou Tin Co. Ltd. | CHINA |

Tin | Nankang Nanshan Tin Manufactory Co., Ltd. | CHINA |

Tin | YUNNAN CHENGFENG NON-FERROUS METALS CO.,LTD | CHINA |

Tin | YunNan GeJiu Jin Ye Mineral Co.,Ltd | CHINA |

Tin | Yunnan Tin Company, Ltd. | CHINA |

Tin | ZhongShi | CHINA |

Tin | KOVOHUTĚ PŘÍBRAM NÁSTUPNICKÁ, A.S. | CZECH REPUBLIC |

Tin | Heraeus Precious Metals GmbH & Co. KG | GERMANY |

Tin | Heraeus Ltd Hong Kong | HONG KONG |

Tin | CV DS Jaya Abadi | INDONESIA |

Tin | CV Duta Putra Bangka | INDONESIA |

Tin | CV Gita Pesona | INDONESIA |

Tin | CV JusTindo | INDONESIA |

Tin | CV Makmur Jaya | INDONESIA |

Tin | CV Nurjanah | INDONESIA |

Tin | CV Prima Timah Utama | INDONESIA |

Tin | CV Serumpun Sebalai | INDONESIA |

Tin | CV United Smelting | INDONESIA |

|

| | |

Tin | PT Alam Lestari Kencana | INDONESIA |

Tin | PT Artha Cipta Langgeng | INDONESIA |

Tin | PT ATD Makmur Mandiri Jaya | INDONESIA |

Tin | PT Babel Inti Perkasa | INDONESIA |

Tin | PT Babel Surya Alam Lestari | INDONESIA |

Tin | PT Bangka Kudai Tin | INDONESIA |

Tin | PT Bangka Putra Karya | INDONESIA |

Tin | PT Bangka Timah Utama Sejahtera | INDONESIA |

Tin | PT Bangka Tin Industry | INDONESIA |

Tin | PT Belitung Industri Sejahtera | INDONESIA |

Tin | PT BilliTin Makmur Lestari | INDONESIA |

Tin | PT Bukit Timah | INDONESIA |

Tin | PT DS Jaya Abadi | INDONESIA |

Tin | PT Eunindo Usaha Mandiri | INDONESIA |

Tin | PT Fang Di MulTindo | INDONESIA |

Tin | PT HP Metals Indonesia | INDONESIA |

Tin | PT Inti Stania Prima | INDONESIA |

Tin | PT Karimun Mining | INDONESIA |

Tin | PT Koba Tin | INDONESIA |

Tin | PT Mitra Stania Prima | INDONESIA |

Tin | PT Panca Mega Persada | INDONESIA |

Tin | PT Pelat Timah Nusantara Tbk | INDONESIA |

Tin | PT REFINED BANGKA TIN | INDONESIA |

Tin | PT Sariwiguna Binasentosa | INDONESIA |

Tin | PT Seirama Tin investment | INDONESIA |

Tin | PT Stanindo Inti Perkasa | INDONESIA |

Tin | PT Sumber Jaya Indah | INDONESIA |

Tin | PT Tambang Timah | INDONESIA |

Tin | PT Timah (Persero), Tbk | INDONESIA |

|

| | |

Tin | PT Tinindo Inter Nusa | INDONESIA |

Tin | PT Tommy Utama | INDONESIA |

Tin | PT Wahana Perkit Jaya | INDONESIA |

Tin | PT Yinchendo Mining Industry | INDONESIA |

Tin | Dowa Metals & Mining Co.Ltd | JAPAN |

Tin | JAPAN NEW METALS CO., LTD. | JAPAN |

Tin | Mitsubishi Materials Corporation | JAPAN |

Tin | Mitsui Mining and Smelting Co., Ltd. | JAPAN |

Tin | Nippon Filler Metals Ltd | JAPAN |

Tin | SENJU METAL INDUSTRY CO.,LTD. | JAPAN |

Tin | Sumitomo Metal Mining Co., Ltd. | JAPAN |

Tin | Hyundai-Steel | KOREA, REPUBLIC OF |

Tin | Poongsan Corporation | KOREA, REPUBLIC OF |

Tin | Malaysia Smelting Corporation (MSC) | MALAYSIA |

Tin | Rahman Hydraulic Tin Berhad | MALAYSIA |

Tin | Amalgament | PERU |

Tin | Minsur | PERU |

Tin | Fenix Metals | POLAND |

Tin | CSC Pure Technologies | RUSSIAN FEDERATION |

Tin | Novosibirsk Integrated Tin Works | RUSSIAN FEDERATION |

Tin | Pure Technology | RUSSIAN FEDERATION |

Tin | Chengfeng Metals Co Pte Ltd | SINGAPORE |

Tin | Electroloy Metal Pte | SINGAPORE |

Tin | Heraeus Materials Singapore Pte, Ltd. | SINGAPORE |

Tin | Rui Da Hung | TAIWAN |

Tin | Koki Products Co.,Ltd | THAILAND |

Tin | O.M. Manufacturing (Thailand) Co., Ltd. | THAILAND |

Tin | Thaisarco | THAILAND |

Tin | Alpha | UNITED STATES |

|

| | |

Tin | Technic, Inc. | UNITED STATES |

Tungsten | Wolfram Bergbau und Hütten AG | AUSTRIA |

Tungsten | North American Tungsten Corporation Ltd. | CANADA |

Tungsten | A.L.M.T. Corp. | CHINA |

Tungsten | Chaozhou Xianglu Tungsten Industry Co Ltd | CHINA |

Tungsten | Chenzhou Diamond Tungsten Products Co., Ltd. | CHINA |

Tungsten | China Minmetals Nonferrous Metals Co Ltd | CHINA |

Tungsten | Chongyi Zhangyuan Tungsten Co Ltd | CHINA |

Tungsten | Dayu Weiliang Tungsten Co., Ltd. | CHINA |

Tungsten | Fujian Jinxin Tungsten Co., Ltd. | CHINA |

Tungsten | Ganzhou Grand Sea W & Mo Group Co Ltd | CHINA |

Tungsten | Ganzhou Huaxing Tungsten Products Co., Ltd. | CHINA |

Tungsten | Ganzhou Jiangwu Ferrotungsten Co., Ltd. | CHINA |

Tungsten | Ganzhou Non-ferrous Metals Smelting Co., Ltd. | CHINA |

Tungsten | Ganzhou Seadragon W & Mo Co., Ltd. | CHINA |

Tungsten | Hunan Chenzhou Mining Group Co | CHINA |

Tungsten | Hunan Chuangda Vanadium Tungsten Company | CHINA |

Tungsten | Hunan Chun-chang Non-ferrous Smelting & Concentrating Co., Ltd. | CHINA |

Tungsten | Jiangsu Hetian Technological Material Co.,Ltd | CHINA |

Tungsten | Jiangxi Gan Bei Tungsten Co., Ltd. | CHINA |

Tungsten | Jiangxi Minmetals Gao’an Non-ferrous Metals Co., Ltd. | CHINA |

Tungsten | Jiangxi Rare Earth & Rare Metals Tungsten Group Corp | CHINA |

Tungsten | Jiangxi Richsea New Materials Co., Ltd. | CHINA |

Tungsten | Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. | CHINA |

Tungsten | Jiangxi Xinsheng Tungsten Industry Co., Ltd. | CHINA |

Tungsten | Jiangxi Yaosheng Tungsten Co., Ltd. | CHINA |

Tungsten | Malipo Haiyu Tungsten Co., Ltd. | CHINA |

Tungsten | Minmetals Ganzhou Tin Co. Ltd. | CHINA |

Tungsten | Nanchang Cemented Carbide Limited Liability Company | CHINA |

|

| | |

Tungsten | Sichuan Metals & Materials Imp & Exp Co | CHINA |

Tungsten | Xiamen Honglu Tungsten Molybdenum Co., Ltd. | CHINA |

Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. | CHINA |

Tungsten | Xiamen Tungsten Co Ltd | CHINA |

Tungsten | Xinhai Rendan Shaoguan Tungsten Co., Ltd. | CHINA |

Tungsten | Zhuzhou Cemented Carbide Group Co Ltd | CHINA |

Tungsten | H.C. Starck GmbH | GERMANY |

Tungsten | A.L.M.T. Corp. | JAPAN |

Tungsten | Izawa Metal | Japan |

Tungsten | Japan New Metals Co Ltd | JAPAN |

Tungsten | JX Nippon Mining & Metals | JAPAN |

Tungsten | Mitsubishi Materials Corporation | JAPAN |

Tungsten | Saganoseki Smelter & Refinery | JAPAN |

Tungsten | Sumitomo Metal Mining Co., Ltd. | JAPAN |

Tungsten | Tamano Smelter, Hibi Kyodo Smelting Co., Ltd | JAPAN |

Tungsten | TaeguTec LTD. | KOREA, REPUBLIC OF |

Tungsten | Pobedit JSC | RUSSIAN FEDERATION |

Tungsten | Wolfram Company CJSC | RUSSIAN FEDERATION |

Tungsten | Air Products | UNITED STATES |

Tungsten | ATI Tungsten Materials | UNITED STATES |

Tungsten | Global Tungsten & Powders Corp. | UNITED STATES |

Tungsten | HC Starck | UNITED STATES |

Tungsten | Kennametal Fallon | UNITED STATES |

Tungsten | Materion Advanced Materials Thin Film Products | UNITED STATES |

Tungsten | Voss Metals Company, Inc. | UNITED STATES |

Tungsten | Vietnam Youngsun Tungsten Industry Co., Ltd | VIETNAM |

Tungsten | Tejing (Vietnam) Tungsten Co., Ltd. | VIETNAM |

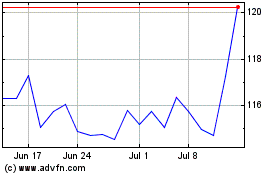

Integer (NYSE:ITGR)

Historical Stock Chart

From Mar 2024 to Apr 2024

Integer (NYSE:ITGR)

Historical Stock Chart

From Apr 2023 to Apr 2024