UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

________________________________________________________

FORM SD

________________________________________________________

SPECIALIZED DISCLOSURE REPORT

FMC Technologies, Inc.

(Exact name of registrant as specified in its charter)

|

| | | | |

Delaware | | 001-16489 | | 36-4412642 |

(State or other jurisdiction of incorporation) | | (Commission File Number) | | (I.R.S. Employer Identification No.) |

|

| | | | |

5875 N. Sam Houston Parkway W., Houston, TX | | | | 77086 |

(Address of principal executive offices) | | | | (Zip Code) |

Lisa P. Wang

Senior Counsel

(281) 591-4000

(Name and telephone number, including area code, of the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

x Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2013.

Section 1 – Conflict Minerals Disclosure

| |

Item 1.01 | Conflict Minerals Disclosure and Report |

FMC Technologies, Inc. (the “Company,” “FMC Technologies,” “we,” “us,” and “our”) evaluated its product lines and determined that certain products that we manufacture or contract to manufacture contain tin, tungsten, tantalum, and/or gold necessary to the functionality or production of such product(s).

A copy of this Form SD and the Conflict Minerals Report filed as Exhibit 1.01 hereto are publicly available on the Company’s Internet web site at http://fmctechnologies.com/AboutUs/HSEStandards.aspx.

Our Conflict Minerals Report is filed as Exhibit 1.01 hereto.

Section 2 – Exhibits

| |

Exhibit No. | Description of Exhibit |

| |

1.01 | Conflict Minerals Report as required by Items 1.01 and 1.02 of Form SD. |

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

FMC TECHNOLOGIES, INC.

(Registrant)

|

| | |

| By: /s/ Dianne B. Ralston | |

Date: June 1, 2015 | Name: Dianne B. Ralston | |

| Title: Senior Vice President, General Counsel and Secretary | |

EXHIBIT INDEX

| |

Exhibit No. | Description of Exhibit |

| |

1.01 | Conflict Minerals Report as required by Items 1.01 and 1.02 of Form SD. |

Exhibit 1.01

FMC Technologies, Inc.

Conflict Minerals Report

for the Year Ended December 31, 2014

1. Introduction

This Conflict Minerals Report describes FMC Technologies, Inc.’s (the “Company,” “FMC Technologies,” “we,” “us,” and “our”) due diligence process in accordance with the requirements of Rule 13p-1 of the Securities Exchange Act of 1934, as amended.

2. Company Overview

We are a global provider of technology solutions for the energy industry. FMC Technologies was incorporated in November 2000 under Delaware law and was a wholly-owned subsidiary of FMC Corporation until our initial public offering in June 2001. Our principal executive offices are located at 5875 North Sam Houston Parkway West, Houston, Texas 77086.

We design, manufacture and service technologically sophisticated systems and products, including subsea production and processing systems, surface wellhead production systems, high pressure fluid control equipment, measurement solutions and marine loading systems for the energy industry. We report our results of operations in the following reporting segments: Subsea Technologies, Surface Technologies and Energy Infrastructure. We evaluated our product lines and determined that certain products that we manufacture or contract to manufacture contain tin, tungsten, tantalum, and/or gold (“3TG”) and such 3TG are necessary to the functionality or production of such product(s).

3. Reasonable Country of Origin Inquiry and Due Diligence

Reasonable Country of Origin Inquiry

To implement the reasonable country of origin (“RCOI”) inquiry, we collected information regarding the presence and sourcing of 3TG used in the products supplied to FMC Technologies. Information was collected and stored using an online platform provided by a third party vendor, Source Intelligence.

Supplier engagement included these steps:

| |

• | We sent communications to our suppliers describing our Conflict Minerals Compliance Program (“CMCP”) requirements and introducing Source Intelligence as our partner in the process; |

| |

• | Source Intelligence sent subsequent correspondence to suppliers containing a registration and questionnaire link for the on-line data collection platform; |

| |

• | Source Intelligence provided the Supplier Resource Center as a supplier education resource to support a deeper understanding of the program and provide background as to why information was being requested (https://conflictmineralsresources.com/); |

| |

• | We requested that our suppliers respond to our questionnaire, which was based off the Conflict-Free Sourcing Initiative (“CFSI”) Conflict Mineral Reporting Template 3.02 (“CMRT”), an initiative of the Electronic Industry Citizen Coalition and Global e-Sustainability Initiative (“EICC GeSI”), to identify the 3TG smelters and refiners from which they source their materials, including the associated countries of origin; |

| |

• | Suppliers were offered two options to submit the required information, either by uploading the CMRT in Microsoft Excel format or by completing an online survey version of this template directly into the Source Intelligence platform; and |

| |

• | Source Intelligence contacted non-responsive suppliers by email and/or telephone and offered assistance. |

Based on our RCOI inquiry, we believe that certain of our products may contain 3TG that originated in the Democratic Republic of the Congo or an adjoining country and are not from recycled or scrap sources. As such, we exercised due diligence on the source and chain of custody of such 3TG.

Due Diligence

Our due diligence process is based on the Organisation for Economic Co-operation and Development’s Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and accompanying supplements (the “OECD Framework”), which is an internationally recognized due diligence framework. All steps taken by us in preparing this Conflict Minerals Report were in accordance with the OECD Framework. A copy of our Form SD, this Conflict Minerals Report and our Conflict Minerals Policy are publicly available on our Internet web site at

http://fmctechnologies.com/AboutUs/HSEStandards.aspx.

For the fiscal year ended December 31, 2014, our due diligence efforts included the following:

| |

• | Reviewed and maintained a conflict minerals policy available at www.fmctechnologies.com/AboutUs/HSEStandards; |

| |

• | Maintained an internal, cross-functional team to support supply chain due diligence; |

| |

• | Updated our strategy to respond to supply chain risks; |

| |

• | Established the annual Email and Phone Verification Program (“EPVP”), which is an internal verification program to establish our suppliers’ Conflict Minerals contacts; |

| |

• | Continued our engagement of Source Intelligence to contact the identified suppliers via email and telephone and manage responses; |

| |

• | Requested suppliers to confirm the presence of 3TG in their products; |

| |

• | Requested documentation from suppliers supporting their responses to our Conflict Minerals Questionnaire; |

| |

• | Evaluated supplier responses for plausibility, consistency and gaps; |

| |

• | Used government websites and smelters’ or refiners’ databases to verify companies identified; |

| |

• | Worked to identify the smelters or refiners in our supply chain; |

| |

• | Reported risk management findings to senior management; and |

| |

• | Reported on supply chain due diligence. |

4. Product Description

We manufacture and contract to manufacture certain products that contain 3TG, such as subsea production and processing systems, surface wellhead production systems, high pressure fluid control equipment, measurement solutions, marine loading systems, remotely operating vehicle systems, manipulator systems, subsea control systems, fracturing flowback services and wireline services for the energy industry.

Suppliers were requested to use the CMRT to identify 3TG smelters and refiners and the associated countries of origin. The table below lists, as of April 30, 2015, the smelters known to supply necessary conflict minerals contained in our covered products and that source their conflict minerals from one or more of the covered countries.

|

| | | |

Metal | Smelter or Refiner | CFSI Certification Status | Mine of Countries of Origin |

Gold | CCR Refinery - Glencore Canada Corporation | Certified | DRC-Congo (Kinshasa), Zambia |

Tantalum | Conghua Tantalum and Niobium Smeltry | Certified | Rwanda |

Tantalum | Duoluoshan Sapphire Rare Metal Co., Ltd. | Certified | Rwanda |

Tantalum | H.C. Starck Co., Ltd. | Certified | Rwanda |

Tantalum | H.C. Starck GmbH Goslar | Certified | Rwanda |

Tantalum | H.C. Starck GmbH Laufenburg | Certified | Rwanda |

Tantalum | H.C. Starck Hermsdorf GmbH | Certified | Rwanda |

Tantalum | H.C. Starck Inc. | Certified | Rwanda |

Tantalum | H.C. Starck Ltd. | Certified | Rwanda |

Tantalum | Hi-Temp Speciality Metals, Inc. | Certified | Rwanda |

Tantalum | Jiujiang Tanbre Co., Ltd. | Certified | DRC-Congo (Kinshasa) |

Tantalum | KEMET Blue Metals | Certified | Burundi, Rwanda |

Tantalum | Kemet Blue Powder | Certified | Burundi, DRC-Congo (Kinshasa), Rwanda |

Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. | Certified | Burundi, Rwanda |

Tantalum | Ulba | Certified | Burundi, DRC-Congo (Kinshasa), Rwanda |

Tantalum | Zhuzhou Cement Carbide | Certified | Burundi, DRC-Congo (Kinshasa), Rwanda |

Tin | China Tin Group Co., Ltd. | Active | DRC-Congo (Kinshasa) |

Tin | CV United Smelting | Certified | DRC-Congo (Kinshasa) |

Tin | Empresa Metallurgica Vinto | Certified | DRC-Congo (Kinshasa) |

Tin | Malaysia Smelting Corporation (MSC) | Certified | DRC-Congo (Kinshasa), Rwanda |

Tin | Metallo Chimique | Certified | DRC-Congo (Kinshasa) |

Tin | Minsur | Certified | DRC-Congo (Kinshasa), Rwanda |

Tin | Operaciones Metalurgical S.A. | Certified | DRC-Congo (Kinshasa) |

Tin | PT Bangka Putra Karya | Certified | DRC-Congo (Kinshasa) |

Tin | PT Bukit Timah | Certified | DRC-Congo (Kinshasa) |

Tin | PT Pelat Timah Nusantara Tbk | Not certified | Burundi, DRC-Congo (Kinshasa), Rwanda |

Tin | PT Stanindo Inti Perkasa | Certified | DRC-Congo (Kinshasa) |

Tin | PT Timah (Persero), Tbk | Certified | DRC-Congo (Kinshasa) |

Tin | Thaisarco | Certified | DRC-Congo (Kinshasa), Rwanda |

Tin | Yunnan Tin Company Limited | Certified | Angola, DRC-Congo (Kinshasa) |

Tungsten | H.C. Starck GmbH | Progressing | Rwanda |

Tungsten | Wolfram Company CJSC | Progressing | Rwanda |

Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. | Certified | Burundi, Rwanda |

Tungsten | Xiamen Tungsten Co., LTd. | Certified | Rwanda |

_______________________

CFSI Certification Status Key:

| |

• | Active: The smelter is actively moving through the certification process. |

| |

• | Progressing: Tungsten smelters that have committed to obtain a certification within two years of membership with the Tungsten Industry-Conflict Minerals Committee (“TI-CMC”). |

5. Steps to Improve Due Diligence

Consistent with our corporate values, we have taken (since January 1, 2015), or will take, the following steps to improve due diligence and further mitigate the risk that necessary conflict minerals contained in our covered products could directly or indirectly finance or benefit armed groups in the covered countries:

| |

• | Continue to assess the presence of 3TG in our supply chain; |

| |

• | Establish clear requirements with suppliers regarding performance, transparency and responsible sourcing; |

| |

• | Increase the response rate for our RCOI process; and |

| |

• | Continue to compare the RCOI results to information collected via independent conflict-free smelter validation programs. |

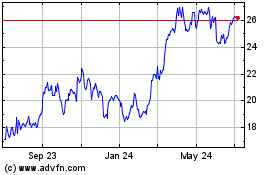

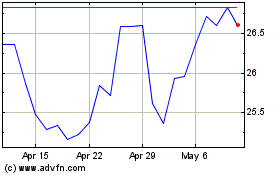

TechnipFMC (NYSE:FTI)

Historical Stock Chart

From Mar 2024 to Apr 2024

TechnipFMC (NYSE:FTI)

Historical Stock Chart

From Apr 2023 to Apr 2024