UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

_________________________________

FORM SD

Specialized Disclosure Report

____________________

Diebold, Incorporated

(Exact name of registrant as specified in its charter)

|

| | | | |

| | | | |

| | | | |

Ohio | | 1-4879 | | 34-0183970 |

| | | | |

(State or other jurisdiction of incorporation or organization) | | (Commission File Number) | | (I.R.S. Employer Identification No.) |

| | | | |

5995 Mayfair Road, P.O. Box 3077, North Canton, Ohio | | | | 44720-8077 |

| | | | |

(Address of principal executive offices) | | | | (Zip Code) |

| | | | |

Elizabeth C. Radigan, Vice President and Chief Ethics and Compliance Officer (330) 490-6046 |

(Name and telephone number, including area code, of the person to contact in connection with this report) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

ý Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014.

Section 1 — Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

Diebold, Incorporated (including its consolidated subsidiaries, the “Company”) is filing this Form SD pursuant to Rule 13p-1 under the Securities Exchange Act of 1934, as amended, for the reporting period from January 1, 2014 to December 31, 2014.

The description of the Company’s reasonable country of origin inquiry (“RCOI”), the results of its RCOI, and the determination it reached as a result of its RCOI are included in its Conflict Minerals Report, attached as an exhibit to this Form SD.

A copy of the Company’s Conflict Minerals Report is filed as Exhibit 1.01 hereto and is publicly available at http://www.diebold.com/Diebold-Asset-Library/Environmental_Stewardship/DBDConflictMineralsReport2014.pdf. The content on, or accessible through, any website referred to in this Form SD is not incorporated by reference into this Form SD unless expressly noted.

Item 1.02 Exhibits

A copy of the Conflict Minerals Report as required by Item 1.01 is provided as Exhibit 1.01 hereto.

Section 2 — Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this report:

Exhibit 1.01 — Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned. |

| | | | |

| | | | |

| Diebold, Incorporated | |

June 1, 2015 | By: | /s/ Jonathan B. Leiken | |

| | Name: | Jonathan B. Leiken | |

| | Title: | Senior Vice President, Chief Legal Officer and Secretary | |

EXHIBIT INDEX

|

| | |

| | |

Exhibit | | |

Number | | Description |

1.01 | | Diebold, Incorporated Conflict Minerals Report |

Exhibit 1.01

CONFLICT MINERALS REPORT

For Diebold, Incorporated

For the Year Ended December 31, 2014

Introduction

This Conflict Minerals Report (the “Report”) of Diebold, Incorporated, including its consolidated subsidiaries (“Diebold,” “we,” or “our”) is filed as an exhibit to Form SD as required by Rule 13p-1 (the “Rule”) under the Securities Exchange Act of 1934, as amended, for the reporting period from January 1, 2014 through December 31, 2014 (the “Reporting Period”).

Forward-looking statements contained in this Report are made based on known events and circumstances at the time of release, and as such, are subject in the future to unforeseen uncertainties and risks. Statements in this Report which express a belief, expectation or intention, as well as those that are not historical fact, are forward-looking statements, including statements related to Diebold’s compliance efforts and expected actions identified in this Report. These forward-looking statements are subject to various risks, uncertainties and assumptions, including, among other matters, Diebold’s customers’ requirements to use certain suppliers, Diebold’s suppliers’ responsiveness and cooperation with Diebold’s due diligence efforts, Diebold’s ability to implement improvements in its conflict minerals program and Diebold’s ability to identify and mitigate related risks in its supply chain. If one or more of these or other risks materialize, actual results may vary materially from those expressed. For a more complete discussion of these and other risk factors, see Diebold’s other filings with the Securities and Exchange Commission (“SEC”), including its Annual Report on Form 10-K for the year ended December 31, 2014 and subsequent Quarterly Reports on Form 10-Q. Diebold makes these statements as of the date of this disclosure, and undertakes no obligation to update them unless otherwise required by law.

This Report has not been audited, nor is an independent private sector audit required for this Report under the Rule, the SEC partial stay of the Rule, and existing SEC guidance.

Reasonable Country of Origin Inquiry and Determination

Diebold identified the potential use of certain necessary minerals (i.e., columbite-tantalite (coltan), cassiterite, gold, wolframite, and their derivatives, which are limited to tantalum, tin, and tungsten) (“Conflict Minerals”) in the production of Diebold manufactured or contracted to manufacture products. Therefore, for the Reporting Period, a reasonable country of origin inquiry (“RCOI”), which was reasonably designed, was launched to determine if any of the Conflict Minerals contained in our products originated in the Democratic Republic of the Congo or an adjoining country (“Covered Country”) or came from recycled or scrap sources.

Diebold engaged its top 184 suppliers that provided parts and materials directly to Diebold for the manufacturing of, or contracting to manufacture of, its products (“First Tier Suppliers”), and used the Conflict Minerals Reporting Template (Revision 3.02) developed by the Conflict-Free Sourcing Initiative (“CFSI template”) to make inquiries of those suppliers about the country of origin of Conflict Minerals contained in Diebold products. Based on both the First Tier Suppliers’ direct responses regarding origin of their Conflict Minerals, and Diebold’s RCOI response validation and data collection, there is a possibility that certain of the Conflict Minerals in our manufactured or contracted to manufacture products for the Reporting Period may have originated in a Covered Country and are not from recycled or scrap sources.

Due Diligence

Design of Due Diligence

Diebold’s due diligence process was designed to conform, in all material respects, with the framework in the Organisation for Economic Co-operation and Development (“OECD”) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and the related Supplements for tin, tantalum, and tungsten and for gold (“OECD Guidance”). The OECD Guidance is an internationally recognized due diligence framework.

Due Diligence Measures Performed

| |

1. | Establish strong company management systems |

Diebold’s due diligence measures were designed and performed by the global procurement group with oversight and guidance from executive leadership, legal, compliance, and internal audit teams, as well as consultants as deemed appropriate. Diebold has a Sustainable Supply Chain Policy, which discloses Diebold’s objective to improve the quality of supply chain disclosure and transparency. This policy has been communicated to our First Tier Suppliers through web-based and other direct communications and is available on our company website at http://www.diebold.com/Diebold-Asset-Library/Environmental_Stewardship/DBDConflictMineralsReport2014.pdf. Diebold also requested our First Tier Suppliers to provide information about the source of Conflict Minerals in their products using the CFSI template.

| |

2. | Identify and assess risks in the supply chain |

Our Chief Supply Chain Officer sent a communication regarding Conflict Minerals to all First Tier Suppliers. We required our First Tier Suppliers to submit responses using the CFSI template and achieved a 100% response rate. In order to maintain accurate information, when an engineering change is used for a new part or a part change, the supplier is prompted to verify no change to its current responses to the CFSI template or submit new and/or updated responses to the CFSI template.

To verify the data received from our First Tier Suppliers, a systematic approach was followed. First, coded logic from the CFSI template built into supplier responses determined whether the answers to the inquiries were a valid response type. Second, the sourcing manager who manages the supplier relationship reviewed the CFSI template provided by the supplier to confirm that the responses were logical and to identify any conflicting information (such as a response in a field stating the supplier does not use gold and then later reporting the gold comes from a Covered Country).

| |

3. | Design and implement a strategy to respond to identified risks |

Diebold has communicated to its First Tier Suppliers that it expects them and, in turn, their suppliers, to adhere to our Sustainable Supply Chain Policy and cooperate in our efforts to gain enhanced supply chain transparency.

| |

4. | Carry out independent third-party audit of smelter’s/refiner’s due diligence practices |

We do not have direct relationships with smelters or refiners of Conflict Minerals. Therefore, we do not carry out audits of these facilities. However, we support audits conducted by third parties by urging our First Tier Suppliers to gather information from their suppliers and the rest of their supply chain in order to accurately complete the CFSI template.

| |

5. | Report annually on supply chain due diligence |

This Report is publicly available on our website at http://www.diebold.com/Diebold-Asset-Library/Environmental_Stewardship/DBDConflictMineralsReport2014.pdf and is filed with the SEC. The content of any website referred to in this Report is not incorporated by reference in this Report.

Results of Review

Smelters/Refiners

We asked our First Tier Suppliers for information about the smelters and refiners that process the Conflict Minerals in our products. All of our First Tier Suppliers provided company-level responses, and none of them identified specific smelters or refiners as having processed the Conflict Minerals in the products we purchased from them. Therefore, because we could not confirm which specific smelters or refiners processed the Conflict Minerals in our products, we have not disclosed the names of any smelters or refiners in this Report.

Countries of Origin

Despite our due diligence efforts and engagement with our First Tier Suppliers, our suppliers did not disclose the countries of origin of the Conflict Minerals in the products we purchased from them. Therefore, we do not have sufficient information to disclose the countries of origin of the Conflict Minerals in our products.

Efforts to Determine Mine or Location of Origin

We have determined that the most reasonable effort we can make to determine the mines or locations of origin on our Conflict Minerals is to seek information from our First Tier Suppliers about the smelters and refiners in our supply chain and to instruct them that we expect them to make the same inquiry of their suppliers. We seek that information by conducting the due diligence measures described in this Report. We were unable to gather the necessary information from our First Tier Suppliers to determine the mine or location of origin of our Conflict Minerals.

Steps to Mitigate Risk

Since the start of the Reporting Period, we have taken or expect to take the following steps to mitigate the risk that our Conflict Minerals benefit armed groups and to improve our due diligence measures. We will continue our efforts to obtain better visibility into our supply chain. As we enter into new supply contracts or renew existing contracts, we intend to add, to the extent possible, provisions to those agreements that would require suppliers to provide information about Conflict Minerals used in parts and materials supplied to us. We intend to continue to urge our suppliers to investigate their supply chains to clarify and eliminate all undetermined or unknown responses. Additionally, we will ensure that CFSI templates are updated on an annual basis by applicable suppliers.

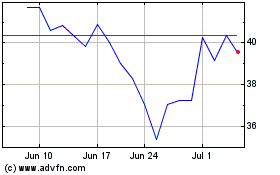

Diebold Nixdorf (NYSE:DBD)

Historical Stock Chart

From Mar 2024 to Apr 2024

Diebold Nixdorf (NYSE:DBD)

Historical Stock Chart

From Apr 2023 to Apr 2024