|

| | | | |

|

| | | | |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549 |

|

FORM SD

|

|

SPECIALIZED DISCLOSURE REPORT

|

|

CATERPILLAR INC.

(Exact name of registrant as specified in its charter) |

|

Delaware

(State or other jurisdiction of incorporation or organization)

|

1-768

(Commission File Number)

| 37-0602744

(IRS Employer Identification No.)

|

100 NE Adams Street, Peoria, Illinois

(Address of principal executive offices)

| 61629

(Zip Code)

|

James B. Buda, Executive Vice President, Law & Public Policy, (309) 675-1000 (Name and telephone number, including area code, of the person to contact in connection with this report) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

|

| |

| |

√ | Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 - Conflict Minerals Disclosure

Items 1.01 and 1.02 Conflict Minerals Disclosure and Report, Exhibit

Conflict Minerals Disclosure

A copy of Caterpillar Inc.’s Conflict Minerals Report for the year ended December 31, 2014 is provided as Exhibit 1.01 hereto and is publicly available at http://www.caterpillar.com/en/investors/sec-filings.html.

Section 2 - Exhibits

Item 2.01 Exhibits

Exhibit 1.01 - Conflict Minerals Report for the year ended December 31, 2014 as required by Items 1.01 and 1.02 of this Form.

* * * * *

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

|

| | | |

|

| | | |

| CATERPILLAR INC. | | |

| (Registrant) | | |

|

| | |

By: | /s/ Edward J. Rapp | | May 29, 2015 |

| Edward J. Rapp | | (Date) |

| Group President, Resource Industries | | |

| | | |

* * * * *

EXHIBIT 1.01

CATERPILLAR INC.

Conflict Minerals Report

For The Year Ended December 31, 2014

Section 1: Introduction and Company Overview

This Conflict Minerals Report (“CMR”) of Caterpillar Inc. (herein referred to as “Caterpillar,” “we,” or “our”) is being filed in accordance with Rule 13p-1 under the Securities Exchange Act of 1934 (“Rule 13p-1”) for calendar year 2014. Unless otherwise defined herein, terms used in this CMR are as defined in Rule 13p-1 and Form SD. References to internet websites herein are provided only as required by Rule 13p-1 and information available through these websites is not incorporated by reference into this Form SD. Statements in this CMR are based on our due diligence activities performed to date in good faith and are based on information available at the time of this filing. Factors that could affect the accuracy of these statements include, but are not limited to, incomplete supplier data, lack of available smelter and refiner data and errors or omissions by suppliers or smelters.

With 2014 sales and revenues of $55.184 billion, Caterpillar is the world’s leading manufacturer of construction and mining equipment, diesel and natural gas engines, industrial gas turbines and diesel-electric locomotives. We principally operate through our three product segments - Construction Industries, Resource Industries and Energy and Transportation - and also provide financing and related services through our Financial Products segment. We are also a leading U.S. exporter. Through a global network of independent dealers and direct sales of certain products, we build long-term relationships with customers around the world.

We manufacture and contract to manufacture products that contain tin, tantalum, tungsten and gold (“3TG”) which is necessary to the functionality and/or production of such products (the “3TG Products”). Our 3TG Products are listed on Schedule A attached hereto. We have relationships with a vast network of suppliers worldwide and we rely on our suppliers to provide information on the origin of the 3TG contained in the components and materials supplied to us. As a downstream purchaser, Caterpillar, in most instances, is many steps removed from the smelters and refiners in our supply chain. To the best of our knowledge, Caterpillar does not purchase 3TG directly from the Democratic Republic of the Congo or in any adjoining country (collectively, the “Covered Countries”). Because of Caterpillar’s size, the complexity of our products and the depth, breadth and constant evolution of our supply chain, it is difficult to identify suppliers upstream from our direct suppliers. Accordingly, we participate in an industry-wide initiative described in Section 3 below. Caterpillar is also an active participant in multiple industry associations which focus on increasing awareness for responsible sourcing of conflict minerals and developing related resources that benefit the entire supply chain.

Caterpillar’s method for determining the country of origin of 3TG contained in our 3TG Products was to conduct a supply-chain survey with direct suppliers using the template developed by the Conflict Free Sourcing Initiative (“CFSI”) known as the Conflict Minerals Reporting Template (the “CMRT”). The CMRT was developed to facilitate disclosure and communication of information regarding smelters and refiners that provide materials to a manufacturer’s supply chain. The CMRT includes questions regarding a direct supplier’s conflict-free policy, its due diligence process and information

about its supply chain, including the names and locations of smelters and refiners as well as the origin of 3TG used by those facilities.

We surveyed approximately 98% of our suppliers known or suspected to provide components and materials for our 3TG Products (“Impacted Suppliers”), which resulted in 46,685 inquiries. Some Impacted Suppliers received multiple inquiries. While we requested that all Impacted Suppliers respond to the survey, we targeted “high-priority” suppliers representing the top 80% of our expenditures for components and materials known or suspected to include 3TG and established an internal escalation process for following up with unresponsive suppliers to increase the response rate with an emphasis on high-priority suppliers. For 2014, we received responses from approximately 94% of these high-priority suppliers equaling 1,981 total responses. Based on these results, we have a reason to believe that some of the 3TG in our supply chain may have originated in the Covered Countries and also have reason to believe that such 3TG may not be from recycled or scrap sources.

In accordance with Rule 13p-1, we undertook due diligence efforts on the source and chain of custody of 3TG in our supply chain. Rule 13p-1 requires that a registrant’s due diligence follow a nationally or internationally recognized due diligence framework. Presently, the only nationally or internationally recognized due diligence framework available is the Organisation for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and related Supplements for each of the conflict minerals (the “OECD Guidance”). The OECD Guidance is a framework for risk-based due diligence for responsible supply chains of conflict minerals from conflict-affected and high-risk areas that is described in the following five-steps: 1) establish strong company management systems; 2) identify and assess risk in the supply chain; 3) design and implement a strategy to respond to identified risks; 4) carry out an independent third-party audit of supply chain due diligence at identified points in the supply chain; and 5) report on supply chain due diligence.

Section 2: Design of Due Diligence Framework

Caterpillar designed its due diligence measures to be in conformity, in all material respects, with the OECD Guidance.

Section 3: Due Diligence Measures Performed

This Section 3 describes measures performed by us to exercise due diligence on the source and chain of custody of 3TG contained in our 3TG Products.

Establish Strong Management Systems

Conflict Minerals Position Statement

Caterpillar has issued a position statement on conflict minerals which states our commitment to the responsible sourcing of conflict minerals used in our products and that we will not knowingly provide support to, contribute to, assist with, or facilitate armed conflict in the Covered Countries. A copy of our conflict minerals position statement is publicly available at http://www.caterpillar.com/en/company/dealers-customers-suppliers/conflict-minerals.html.

Systems of Controls and Transparency

We rely on our suppliers to provide information on the origin of the 3TG contained in the components and materials supplied to us. Caterpillar is a member of the CFSI (Member ID: CATE), an initiative of the Electronics Industry Citizenship Coalition and the Global e-Sustainability Initiative developed to identify and disclose upstream actors in the supply chain, including 3TG smelters and refiners, to determine red flag locations of 3TG origin in the supply chain. CFSI program initiatives include the Conflict-Free Smelter Program (“CFSP”) which identifies smelters and refiners that process materials from conflict-free sources, and the CMRT which is a free, standardized reporting template that facilitates the transfer of information through the supply chain regarding the country of origin of 3TG and smelters and refiners being utilized. We sent letters to a sampling of smelters and refiners not currently participating in the CFSP, both directly and through our participation on the CFSI Smelter Engagement Team, to encourage them to participate in the CFSP.

We have a document retention policy that includes relevant records relating to our conflict minerals compliance program.

Internal Management Systems

We established a management system to manage our conflict minerals compliance program by designating a group of cross-functional senior leaders to be responsible for the oversight of our conflict minerals compliance program, which includes executive-level representatives. In addition, a project team with senior-level managers was responsible for the development and deployment of our conflict minerals compliance program.

Supplier Engagement

As stated in our conflict minerals position statement, our strategy is to establish long-term relationships and collaborate with our suppliers. To communicate our expectations relating to responsible sourcing of conflict minerals, Caterpillar sent notices to our Impacted Suppliers and has issued our position statement on conflict minerals referenced above. We developed and made available a web-based training presentation to suppliers on topics including the relevant requirements of Rule 13p-1, Caterpillar’s obligations under Rule 13p-1 and instructions for responding to the CMRT. We also updated the language in our standard purchase order terms and conditions to require our suppliers to provide us with supporting information and documentation evidencing due diligence of 3TG in their respective supply chains upon our request for such information.

Company Level Grievance Mechanism

In 1974, Caterpillar first introduced a Worldwide Code of Conduct called “Our Values in Action”. Our Values in Action articulates our long-standing support for, and commitment to, human rights and the dignity of all people. Our employees and management participate in annual assessments that provide awareness of and apply the principles contained in Our Values in Action. Our Values in Action requires employees to report any circumstance or action that violates, or appears to violate, Our Values in Action, enterprise policy or applicable law, and we maintain methods for employees and other interested parties to confidentially report such circumstances or actions.

Identify and Assess Risks in the Supply Chain

Our method for determining the country of origin of 3TG contained in our 3TG Products was to conduct a supply-chain survey with Impacted Suppliers using the Template.

We rely on our suppliers to provide information on the origin of 3TG contained in the components and materials supplied to us. These suppliers are similarly reliant upon information provided by their suppliers. We reviewed Impacted Supplier responses against criteria developed by our internal team to determine whether further engagement was necessary. Smelters and refiners identified by a supplier in response to our supply-chain survey are also compared against the list of facilities that have received a “conflict-free” designation by the CFSP which provides country of origin and due diligence information on the conflict minerals sources by such facilities.

Design and Implement a Strategy to Respond to Identified Risks

We have a supply chain risk management plan that outlines our response to risks identified in our supply chain. Members of our senior management are apprised of actual and potential risks and red flags identified in our supply chain. As part of our risk management plan and to assist our Impacted Suppliers in understanding our expectations, we request our Impacted Suppliers that do not respond to the supply-chain survey referenced above or that provide incomplete or inconsistent responses to the survey to complete a training program. We have established a risk mitigation plan that identifies areas of risk on an ongoing basis and subjects suppliers that we identify to corrective action plans to mitigate or remediate such risks. Our risk mitigation plan provides that any supplier’s failure to take corrective actions when required may lead to additional actions, up to and including the termination of our business relationship.

Carry Out Independent Third Party Audit of Smelter/Refiner’s Due Diligence Practices

We support audits of 3TG smelters and refiners through our participation in, and financial support of, the CFSP. To the best of our knowledge, we do not have a direct relationship with 3TG smelters or refiners and do not perform direct audits of these entities within our supply network.

Report Annually on Supply Chain Due Diligence

We are filing this CMR with the Securities and Exchange Commission, which is also publicly available on our website at http://www.caterpillar.com/en/investors/sec-filings.html.

Section 4: Due Diligence Results

Based on the information provided by Impacted Suppliers in the supply-chain survey and the due diligence measures described above, we have reason to believe that one supplier sourced tin for use in parts and components supplied to Caterpillar from smelters PT Refined Bangka Tin and Thaisarco. Furthermore, based on the information obtained pursuant to the due diligence measures described above, we reasonably determined that the tin processed by these

smelters may be from the countries of origin listed on Schedule B attached hereto. However, each of these smelters was identified as validated conflict-free sources under the CFSP.

With regard to the other responses to our supply-chain survey that identified specific smelters or refiners, to the extent they were valid smelters and refiners, we cannot be certain that the identified smelters and refiners supplied 3TG for parts and components supplied to Caterpillar rather than to other customers. For this reason, with the exception of the tin supplier noted above, we have been unable to identify with confidence the specific facilities used to process the 3TG in our 3TG Products, the country of origin or the mine or location of origin of the 3TG in our 3TG Products.

Section 5: Efforts to Determine the Mine or Location of Origin

Caterpillar’s efforts to determine the mines or locations of origin of the 3TG in our supply chain include providing financial and in-kind support to the CFSI, continued implementation of the due diligence measures described above including conducting surveys of our Impacted Suppliers utilizing the CMRT.

Section 6: Steps to be Taken to Mitigate Risk

Caterpillar intends to take the following steps to improve the due diligence conducted to further mitigate the risk that the necessary conflict minerals contained in our products benefit armed groups in the Covered Countries, including:

|

| | | | | |

| | | | |

| | |

| • Continue to engage suppliers by providing them with training resources in connection with our supply-chain survey to attempt to increase supplier response rates, improve the content of supplier responses and reduce the number of non-responsive suppliers; | |

| |

| • Continue to require suppliers in new or renewed contracts to provide information about the source of 3TG contained in components and materials supplied to us; |

| |

| • Continue to work with the CFSI to expand the smelters and refiners participating in the CFSP; and |

| |

| • Continue to encourage suppliers that manufacture components or materials containing 3TG to source them from validated smelters when sufficient options exist for procuring conflict-free materials. |

Forward-Looking Statements

Certain statements in this report relate to future events and expectations and are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Words such as “believe,” “estimate,” “will be,” “will,” “would,” “expect,” “anticipate,” “plan,” “project,” “intend,” “could,” “should” or other similar words or expressions often identify forward-looking statements. Examples of forward-looking statements include statements relating to our future plans, and any other statement that does not directly relate to any historical or current fact. Forward-looking statements are based on our current expectations and assumptions, which may not prove to be accurate. These statements are not guarantees and are subject to risks, uncertainties and changes in circumstances that are difficult to predict. Actual

outcomes and results may differ materially from these forward-looking statements. As a result, these statements speak only as of the date they are made and we undertake no obligation to update or revise any forward-looking statement, except as required by federal securities laws.

Schedule A to

Conflict Minerals Report

Description of Caterpillar Products

Articulated Trucks

Backhoe Loaders

Components and Systems, which includes machinery components and electronics and control systems

Diesel-electric Locomotives and Components

Excavators, which includes mini excavators, wheeled excavators and small, medium and large track excavators

Forestry Products

Large Mining Trucks

Motor Graders

Off-Highway Trucks

Other Rail-related Products

Other Products, which includes telehandlers, remanufactured components, OEM and custom products, service parts and service tools

Paving Products, which includes mid-tier soil compactors

Pipelayers

Reciprocating Engines, which includes reciprocating engine powered generator sets, reciprocating engines supplied to the industrial industry as well as Caterpillar machinery, integrated systems used in the electric power generation industry and reciprocating engines and integrated solutions for the marine and oil and gas industries

Select Work Tools

Skid Steer Loaders, which includes compact track loaders and multi-terrain loaders

Surface Mining Equipment, which includes electric rope shovels, hydraulic shovels, draglines and drills

Track Type Tractors and Loaders, which includes small track-type tractors, medium track-type tractors, large track-type tractors and track-type loaders

Turbines

Underground Mining Equipment, which includes highwall miners, longwall miners and hard rock vehicles

Waste and Material Handler Products, which includes wheel dozers

Wheel Loaders, which includes compact wheel loaders, small wheel loaders, medium wheel loaders and large wheel loaders

Wheel Tractor Scrapers

Schedule B to

Conflict Minerals Report

Countries of Origin

Angola, Argentina, Australia, Austria, Belgium, Bolivia, Brazil, Burundi, Canada, Central African Republic, Chile, China, Colombia, Côte d’Ivoire, Czech Republic, Djibuti, Egypt, Estonia, Ethiopia, France, Germany, Guyana, Hungary, India, Indonesia, Ireland, Israel, Japan, Kazakhstan, Laos, Luxembourg, Madagascar, Malaysia, Mongolia, Myanmar, Netherlands, Nigeria, Peru, Portugal, Republic of Congo, Russia, Rwanda, Sierra Leone, Singapore, Slovakia, South Korea, Spain, Suriname, South Sudan, Switzerland, Taiwan, Tanzania, Thailand, Uganda, United Kingdom, United States of America, Vietnam, Zambia and Zimbabwe.

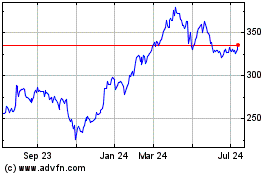

Caterpillar (NYSE:CAT)

Historical Stock Chart

From Mar 2024 to Apr 2024

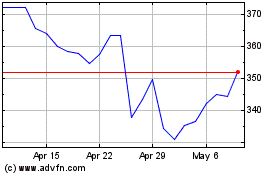

Caterpillar (NYSE:CAT)

Historical Stock Chart

From Apr 2023 to Apr 2024