United States

Securities and Exchange Commission

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

ALCOA INC.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| Pennsylvania |

|

1-3610 |

|

25-0317820 |

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

|

|

|

| 390 Park Avenue

New York, New York |

|

10022-4608 |

| (Address of principal executive offices) |

|

(Zip Code) |

Office of Investor Relations 212-836-2674

Office of the Secretary 212-836-2732

(Name and telephone number, including area code, of the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 – Conflict Minerals Disclosure

| Item 1.01 |

Conflict Minerals Disclosure and Report |

Overview

Unless the context indicates otherwise, the terms “Alcoa,” “Company,” “we,” “its,” “us” and “our”

refer to Alcoa Inc. and all subsidiaries consolidated for the purposes of its financial statements that were in-scope for the 2014 compliance period. The “Conflict Minerals Rule” means, collectively, Rule 13p-1 under the Securities

Exchange Act of 1934, as amended, and Form SD. As used herein and consistent with the Conflict Minerals Rule, “Conflict Minerals” are columbite-tantalite (coltan), cassiterite, gold, wolframite and the derivatives tantalum, tin and

tungsten, without regard to the location of origin of the minerals or derivative metals.

See the Conflict Minerals Report filed as an exhibit to this

report (“Conflict Minerals Report”) for information regarding the applicability of the Conflict Minerals Rule to the Company generally.

Reasonable Country of Origin Inquiry Information

We

conducted a “reasonable country of origin inquiry” (“RCOI”) within the meaning of the Conflict Minerals Rule to determine the origin of the necessary Conflict Minerals contained in our in-scope products. To the extent applicable,

we utilized the same processes and procedures that we used for our due diligence described in the Conflict Minerals Report. We designed our due diligence measures relating to Conflict Minerals to conform with, in all material respects, the criteria

set forth in the Organisation for Economic Co-operation and Development’s Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, including the

Supplement on Tin, Tantalum and Tungsten and the Supplement on Gold (Second Edition 2013). For a discussion of the due diligence measures that we performed in respect of 2014, see the Conflict Minerals Report.

Based on our RCOI, we determined that the necessary tin contained in certain of our in-scope products originated from a smelter that we believe, based on

publicly available information, sourced all of its ore from outside of the Democratic Republic of the Congo (the “DRC”) and its adjoining countries or from recycled or scrap sources. These products were selected titanium alloys

manufactured by our power and propulsion business unit and a wrought aluminum alloy product manufactured by our forgings and extrusions business unit. None of these products contained Conflict Minerals from any other sources.

In connection with our RCOI, we determined that we either purchased tantalum, tin or tungsten in the form of

recycled or scrap material or purchased tantalum, tin or tungsten directly from sources that we reasonably believe sourced tantalum, tin or tungsten only from recycled or scrap content for at least part of 2014. The products that contained

Conflict Minerals that we reasonably believe came from recycled or scrap sources also contained other Conflict Minerals for which we were not able to determine the origin. These products are described in the Conflict Minerals Report.

As required by the Conflict Minerals Rule, the foregoing information is available at the following Internet website: http://www.alcoa.com. The information

contained on our website is not incorporated by reference into this Form SD or our Conflict Minerals Report and should not be considered part of this Form SD or our Conflict Minerals Report.

Conflict Minerals Report

As required by the Conflict

Minerals Rule, a Conflict Minerals Report is provided as an exhibit to this Form SD and is available at the following Internet website: http://www.alcoa.com.

The Conflict Minerals Report required by Item 1.01 is filed as Exhibit 1.01 to this Form

SD.

Section 2 – Exhibits

Exhibit 1.01 – Conflict Minerals Report for the calendar year ended December 31,

2014

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

|

|

|

|

|

|

| Alcoa Inc. |

|

|

|

|

| (Registrant) |

|

|

|

|

|

|

|

|

| By: |

|

/s/ Audrey Strauss |

|

|

|

June 1, 2015 |

| Name: |

|

Audrey Strauss |

|

|

|

|

| Title: |

|

Executive Vice President, Chief Legal Officer

and Secretary |

|

|

|

|

EXHIBIT INDEX

|

|

|

| Exhibit |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report for the calendar year ended December 31, 2014 |

Exhibit 1.01

Conflict Minerals Report

Alcoa Inc. has

included this Conflict Minerals Report as an exhibit to its Form SD for 2014 as required by Rule 13p-1 under the Securities Exchange Act of 1934, as amended, and Form SD (collectively, the “Conflict Minerals Rule”).

Unless the context indicates otherwise, the terms “Alcoa,” “Company,” “we,” “its,” “us” and “our”

refer to Alcoa Inc. and all subsidiaries consolidated for the purposes of its financial statements that were in-scope for the 2014 compliance period. As used herein and consistent with the Conflict Minerals Rule, “Conflict Minerals” are

columbite-tantalite (coltan), cassiterite, gold, wolframite and the derivatives tantalum, tin and tungsten, without regard to the location of origin of the minerals or derivative metals.

Forward-Looking Statements

Certain statements in this

report relate to future events and expectations, and as such constitute forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include those containing such words as

“anticipates,” “believes,” “estimates,” “expects,” “forecasts,” “hopes,” “intends,” “outlook,” “plans,” “projects,” “should,”

“targets,” “will,” “will likely result,” “would,” or other words of similar meaning. All statements that reflect Alcoa’s expectations, assumptions, or projections about the future other than statements of

historical fact are forward-looking statements, including, without limitation, statements concerning the additional steps that Alcoa intends to take to mitigate the risk that its necessary Conflict Minerals finance or benefit armed groups.

Forward-looking statements are subject to risks and uncertainties that could cause actual actions or performance to differ materially from those expressed in

the forward-looking statements. These risks and uncertainties may include, but are not limited to, (1) the continued implementation of satisfactory traceability and other compliance measures by our direct and indirect suppliers on a timely

basis or at all, (2) whether smelters and refiners and other market participants responsibly source Conflict Minerals, and (3) political and regulatory developments, whether in the Democratic Republic of the Congo (“DRC”) region,

the United States or elsewhere and the other risk factors summarized in Alcoa’s Form 10-K for the year ended December 31, 2014, and other reports filed with the Securities and Exchange Commission (the “SEC”). Alcoa disclaims any

obligation to update publicly any forward-looking statements, whether in response to new information, future events or otherwise, except as required by applicable law.

Alcoa is a global leader in lightweight metals engineering and manufacturing.

Alcoa’s innovative, multi-material products, which include aluminum, titanium, and nickel, are used worldwide in aircraft, automobiles, commercial transportation, packaging, building and construction, oil and gas, defense, consumer electronics,

and industrial applications. Alcoa is also the world leader in the production and management of primary aluminum, fabricated aluminum, and alumina combined, through its active participation in all major aspects of the industry: technology, mining,

refining, smelting, fabricating, and recycling.

1

We are subject to the Conflict Minerals Rule because Conflict Minerals are necessary to the functionality or

production of certain discrete products and product lines manufactured by Alcoa (these Conflict Minerals are sometimes referred to herein as “necessary Conflict Minerals”). Necessary Conflict Minerals content constitutes a small portion of

the materials content of our products.

As a general matter concerning Alcoa’s products, alumina, most primary aluminum products, most aluminum

rolled products and many engineered products do not contain any Conflict Minerals. For a further discussion of our products, see our Annual Report on Form 10-K for the fiscal year ended December 31, 2014. The information contained in our Form

10-K is not incorporated by reference into this Conflict Minerals Report or our Form SD and should not be considered part of this Conflict Minerals Report or our Form SD.

We have filed this Conflict Minerals Report because, for 2014, some of our in-scope products contained Conflict Minerals that either were of an undetermined

origin or were processed by a compliant smelter that we believe, based on publicly available information, may have sourced a portion of its ore from the DRC or an adjoining country. Through the date of this report, we are unaware and have no

knowledge that any of the necessary Conflict Minerals contained in our in-scope products directly or indirectly financed or benefitted armed groups in the DRC or an adjoining country. However, we make no assertion that any of our products are

“DRC conflict free.” The terms “adjoining country,” “armed group” and “DRC conflict free” have the meanings contained in the Conflict Minerals Rule.

See “Product, Smelter and Country of Origin Information” below for information concerning our in-scope products, identified smelters and country of

origin information.

For 2014, we generally did not directly source Conflict Minerals from smelters, and we did not have direct relationships with any

Conflict Minerals mines. We therefore have limited influence over these upstream parties. Furthermore, because of the depth and geographic diversity of our supply chain for certain of our businesses, and due to competitive factors, we often have

significant difficulty identifying market participants that are upstream from our direct suppliers.

| II. |

Reasonable Country of Origin Inquiry Information |

See the Form SD to which this Conflict Minerals

Report is an exhibit for a discussion of the “reasonable country of origin inquiry” that we conducted.

2

Due Diligence Program Design

We designed our due diligence measures relating to Conflict Minerals to conform with, in all material respects, the criteria set forth in the Organisation for

Economic Co-operation and Development’s Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, including the Supplement on Tin, Tantalum and Tungsten and the Supplement on Gold (Second

Edition 2013) (the “OECD Guidance”).

The OECD Guidance has established a five-step framework for due diligence as a basis for responsible

global supply chain management of minerals from conflict-affected and high-risk areas. Our application of the OECD Guidance in respect of 2014 is discussed below. The headings for each of the steps in the next section conform to the headings used in

the OECD Guidance for each of its five steps.

Due Diligence Program Execution

In furtherance of our Conflict Minerals due diligence, we performed the following due diligence measures in respect of 2014. These were not all of the discrete

measures that we took in furtherance of our Conflict Minerals compliance program or pursuant to the Conflict Minerals Rule and the OECD Guidance.

1. OECD Guidance Step One: “Establish strong company management systems”

| |

a. |

We maintain a team that ultimately reports to the Chief Procurement Officer and the Chief Legal Officer charged with managing our Conflict Minerals compliance strategy. The following functional areas were represented on

the working group: external reporting; legal; and procurement. We also appointed representatives from each reporting segment or business unit with potentially in-scope products. Selected internal personnel were educated on the Conflict Minerals

Rule, our compliance plan and the procedures for reviewing and validating supplier responses to our inquiries. In 2014, we provided selected internal personnel with additional training on such procedures in the form of a webinar by specialist

outside counsel and related materials. We also used specialist outside counsel to assist us with other aspects of our compliance efforts in 2014. |

| |

b. |

Alcoa’s procurement function maintains a standard operating procedure (“SOP”) governing purchases of Conflict Minerals. The SOP defines the processes that our procurement function uses to source Conflict

Minerals and to support the annual disclosure of country of origin information for those minerals. The SOP provides that we will only purchase Conflict Minerals from suppliers that can provide acceptable certification that the minerals did not

originate from sources where they directly or indirectly financed or benefitted armed groups in the DRC or its adjoining countries. |

| |

c. |

We used the Conflict Minerals Reporting Template (“CMRT”) developed by the Conflict-Free Sourcing Initiative (“CFSI”) to identify

smelters and refiners in our |

3

| |

supply chain. We will maintain business records relating to Conflict Minerals due diligence, including records of due diligence processes, findings and resulting decisions, in a structured

computerized database, for at least five years. |

| |

d. |

We furnished our direct suppliers that we determined to be potentially in-scope for purposes of our compliance with the Conflict Minerals Rule (the “Suppliers”) with an introductory email, a letter containing

additional guidance on the information they needed to provide based on the source of the Conflict Minerals used by them and a blank copy of the CMRT for their use in responding. |

| |

e. |

We have a mechanism for employees, suppliers and other interested parties to report violations of our Conflict Minerals program compliance requirements. |

2. OECD Guidance Step Two: “Identify and assess risk in the supply chain”

| |

a. |

We determined which of our products were in-scope or potentially in-scope for purposes of our compliance with the Conflict Minerals Rule through product specifications, bills of material, supplier inquiries, elemental

composition limits, spectrographic analysis of the product composition and other information known to us. |

| |

b. |

We requested by email that the Suppliers provide us with information concerning the usage and source of Conflict Minerals in their products that we identified as being or potentially being in-scope, as well as

information on the smelters and refiners in the supply chains of those products. We requested that Suppliers provide their response by submitting a completed CMRT. In 2014, one of our downstream businesses retained a third-party contractor to

conduct its outreach to Suppliers and collect and compile their responses. This resulted in an improved Supplier response rate for this business. In 2014, our overall Supplier response rate improved from 49% to 69%, at least in part as a result of

improved execution of our due diligence program. |

| |

c. |

We reviewed the completed responses received from Suppliers and followed up with Suppliers where we determined it to be appropriate in accordance with our internal written evaluation criteria. |

| |

d. |

To the extent that a completed response identified a smelter or refiner in our supply chain, we reviewed this information against the lists of compliant smelters and refiners published by the CFSI and other publicly

available information. In 2014, we achieved increased transparency in this supply chain through the identification by our Suppliers of twenty-five additional smelters, compared with the eight smelters identified in 2013. |

4

3. OECD Guidance Step Three: “Design and implement a strategy to respond to identified risks”

| |

a. |

Our Conflict Minerals compliance team reported its findings to our Chief Procurement Officer and Chief Legal Officer. |

| |

b. |

Under our risk mitigation strategy, we take such risk mitigation efforts as we deem to be appropriate based on the findings of our supply chain risk assessment. Our risk mitigation efforts are determined by the

particular facts and circumstances and risks identified. |

| |

c. |

To mitigate the risk that our necessary Conflict Minerals finance or benefit armed groups, we also intend to engage in the additional measures discussed under “Additional Risk Mitigation Efforts” below.

|

4. OECD Guidance Step Four: “Carry out independent third-party audit of supply chain due diligence at

identified points in the supply chain”

In connection with our due diligence, we utilized information made available by the CFSI

concerning independent third-party audits of smelters and refiners.

5. OECD Guidance Step 5: “Report on supply chain due

diligence”

We have filed a Form SD and this Conflict Minerals Report with the SEC and made available on our website the Form SD

and this Conflict Minerals Report.

| IV. |

Product, Smelter and Country of Origin Information |

Product Information

For 2014, the following in-scope products had necessary Conflict Minerals that originated or may have originated from the DRC or its adjoining countries:

(1) certain investment cast airfoils (superalloy) and investment cast structures (superalloy, aluminum and titanium); (2) certain fastening systems or components; (3) certain building and construction products; (4) coated

aluminum commercial vehicle wheels; (5) a wrought aluminum alloy product; and (6) an aluminum alloy billet product.

Smelter Information

The Suppliers identified to us the facilities listed below as having processed the necessary Conflict Minerals contained in the in-scope products

described above. The smelters listed below may not be all of the facilities used to process the necessary Conflict Minerals in our supply chain, since not all of the Suppliers responded to our request and the Suppliers that did respond to our

request in some cases did not identify the processors of all of the Conflict Minerals content contained in these products.

5

|

|

|

|

|

| Metal |

|

Smelter Facility Name (1) |

|

Status (2) |

|

|

|

| Tantalum |

|

Conghua Tantalum and Niobium Smeltry |

|

Compliant |

|

|

|

| Tantalum |

|

Duoluoshan |

|

Compliant |

|

|

|

| Tantalum |

|

Exotech Inc. |

|

Compliant |

|

|

|

| Tantalum |

|

FIR Metals & Resource Co., Ltd |

|

Compliant |

|

|

|

| Tantalum |

|

Global Advanced Metals |

|

Compliant |

|

|

|

| Tantalum |

|

H.C. Starck GmbH Goslar |

|

Compliant |

|

|

|

| Tantalum |

|

H.C. Starck GmbH Laufenburg |

|

Compliant |

|

|

|

| Tantalum |

|

H.C. Starck Hermsdorf GmbH |

|

Compliant |

|

|

|

| Tantalum |

|

H.C. Starck Ltd. |

|

Compliant |

|

|

|

| Tantalum |

|

H.C. Starck Smelting GmbH & Co.KG |

|

Compliant |

|

|

|

| Tantalum |

|

Hi-Temp |

|

Compliant |

|

|

|

| Tantalum |

|

LSM Brasil S.A. |

|

Compliant |

|

|

|

| Tantalum |

|

Molycorp Silmet A.S. |

|

Compliant |

|

|

|

| Tantalum |

|

Plansee |

|

Compliant |

|

|

|

| Tantalum |

|

Plansee SE Reutte |

|

Compliant |

|

|

|

| Tantalum |

|

RFH Tantalum Smeltry Co., Ltd |

|

Compliant |

|

|

|

| Tantalum |

|

Telex |

|

Compliant |

|

|

|

| Tantalum |

|

Ulba |

|

Compliant |

|

|

|

| Tantalum |

|

Zhuzhou Cement Carbide |

|

Compliant |

|

|

|

| Tin |

|

Malaysia Smelting Corporation |

|

Compliant |

|

|

|

| Tin |

|

Minsur |

|

Compliant |

|

|

|

| Tin |

|

PT Mitra Stania Prima |

|

Compliant |

|

|

|

| Tungsten |

|

ATI Metalworking Products |

|

Not Certified |

|

|

|

| Tungsten |

|

China Minmetals Non-ferrous Metals Holding Co., Ltd. |

|

Compliant |

|

|

|

| Tungsten |

|

Ganzhou Huaxing Tungsten Products Co., Ltd. |

|

Compliant |

|

|

|

| Tungsten |

|

Ganzhou Seadragon W & Mo Co., Ltd. |

|

Compliant |

|

|

|

| Tungsten |

|

Global Tungsten & Powders Corp. |

|

Compliant |

|

|

|

| Tungsten |

|

Ganzhou Non-ferrous Metals Smelting Co., Ltd. |

|

Active |

|

|

|

| Tungsten |

|

Hunan Chunchang Nonferrous Metals Co., Ltd. |

|

Compliant |

6

|

|

|

|

|

|

|

|

| Tungsten |

|

Jiangxi Rare Earth & Rare Metals Tungsten Group Corp |

|

Progressing

Toward CFSP

Validation |

|

|

|

| Tungsten |

|

Sanher Tungsten Vietnam Co., Ltd. |

|

Active |

|

|

|

| Tungsten |

|

Xiamen Tungsten (H.C.) Co., Ltd. |

|

Compliant |

|

|

|

| Tungsten |

|

Xiamen Tungsten Co., Ltd. |

|

Compliant |

| 1 |

Smelter facility names are as listed by the CFSI. |

| 2 |

“Compliant,” “Active” and “Progressing Toward CFSP Validation” have the meanings given to those terms by the CFSI and indicate status as publicly listed by the CFSI as of May 27, 2015,

without independent verification by us. |

Country of Origin Information

The countries of origin disclosed to us by the Suppliers or otherwise known to us for the foregoing facilities were: China, the DRC, Peru and Rwanda. However,

if a smelter sourced from multiple countries, we were not able to determine the country of origin of the Conflict Minerals specific to our products. Therefore, not all of the countries of origin listed above may apply to the Conflict Minerals in our

in-scope products. We do not have country of origin information for Conflict Minerals processed by some of the smelters listed above.

Some of

Alcoa’s products described above that contained Conflict Minerals for which we were not able to determine the origin also contained Conflict Minerals that, based on our reasonable country of origin inquiry, we believe came from recycled or

scrap sources.

We sought to determine the mine or location of origin of the necessary Conflict Minerals contained in our in-scope products by requesting

that the Suppliers provide us with a completed CMRT. Where a smelter or refiner was identified, we also reviewed publicly available information, to the extent available, to try to determine the mine or location of origin.

| V. |

Additional Risk Mitigation Efforts |

We intend to take the following additional steps in respect of our

2015 compliance to mitigate the risk that the necessary Conflict Minerals in our in-scope products finance or benefit armed groups:

| |

1. |

Continue to encourage Suppliers that provided company level information for 2014 to provide product level information for 2015 through ongoing outreach with these Suppliers. |

| |

2 |

Engage with Suppliers that provided incomplete responses or that did not provide responses for 2014 to help ensure that they provide requested information for 2015. |

| |

3. |

Monitor and encourage the continuing development and progress of traceability measures at Suppliers that indicated for 2014 that the source of Conflict Minerals was unknown or undeterminable. |

7

| |

4. |

Communicate to new potentially in-scope suppliers our sourcing expectations. In addition, as new in-scope suppliers are added, work with these suppliers to help ensure that they understand our compliance requirements,

the requirements of the Conflict Minerals Rule and the OECD Guidance. We began to implement a new supplier on-boarding process in late 2014, which we intend to implement more fully in 2015. |

All of the foregoing steps are in addition to the steps that we took in respect of 2014, which we intend to continue to take in respect of 2015 to the extent

applicable.

8

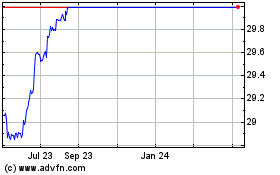

Arconic (NYSE:ARNC)

Historical Stock Chart

From Mar 2024 to Apr 2024

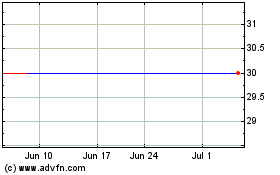

Arconic (NYSE:ARNC)

Historical Stock Chart

From Apr 2023 to Apr 2024