UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

ASML Holding

N.V.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| The Netherlands |

|

025566 |

|

Not Applicable |

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission

File Number) |

|

(IRS Employer

Identification No.) |

De Run 6501

5504 DR Veldhoven

The

Netherlands

(Address of principle executive offices) (Zip Code)

James A. McDonald

Skadden, Arps, Slate, Meagher & Flom (UK) LLP

40 Bank Street, Canary Wharf, London E14 5DS England

(Name and telephone number, including area code, of the person to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 – Conflict Minerals Disclosure

Items 1.01 and 1.02 Conflict Minerals Disclosure and Report

A Conflict Minerals Report is provided as Exhibit 1.01 to this Specialized Disclosure Report and is available at the following Internet address: www.asml.com

Section 2 – Exhibits

Exhibit 1.01- Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly

authorized undersigned.

|

|

|

|

|

|

|

|

|

|

|

|

|

ASML HOLDING N.V. (Registrant) |

|

|

|

|

| Date: May 28, 2015 |

|

|

|

By: |

|

/s/ Peter T.F.M. Wennink |

|

|

|

|

|

|

Peter T.F.M. Wennink |

|

|

|

|

|

|

Chief Executive Officer |

EXHIBIT INDEX

|

|

|

| Exhibit

No. |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report for the year ended December 31, 2014 |

Exhibit 1.01

Conflict Minerals Report

For the Year Ended December 31, 2014

In an effort to curb the violence and exploitation occurring in the Democratic Republic of the Congo (“DRC”) and adjoining regions, the Securities

and Exchange Commission (“SEC”) adopted rules pursuant to Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act (the “Dodd-Frank Act”). Section 1502 of the legislation addresses conflict minerals

and requires companies to publicly disclose information related to the use in their products of minerals originating in the DRC and the countries adjoining the DRC (“Covered Countries”), including the Central African Republic, South Sudan,

Zambia, Angola, The Republic of Congo, Tanzania, Burundi, Rwanda and Uganda. The minerals currently subject to SEC’s disclosure requirements, referred to as “conflict minerals,” are columbite-tantalite (coltan), cassiterite,

wolframite and gold, and their derivatives, including tin, tantalum and tungsten (“3TG”). This Conflict Minerals Report is filed pursuant to Section 1502 of the Dodd-Frank Act.

We have not obtained an independent private sector audit of this Conflict Minerals Report.

Business Overview

ASML designs, develops, integrates,

markets and services advanced lithography systems used by our customers—the major global integrated circuit manufacturers—to create chips that power a wide array of electronic, communication, and information technology products. Our

product development strategy focuses on the development of product families based on a modular, upgradeable design.

Our older PAS 2500 and PAS 5000

lithography systems, which we no longer manufacture but continue to refurbish, are used with g-line and i-line light sources for processing wafers up to 150 mm in diameter and are employed in manufacturing environments and in special applications

for which semiconductor design resolutions of 0.5 microns and above are required. Our PAS 5500 product family comprises advanced wafer steppers and Step-and-Scan systems equipped with i-line, KrF and ArF light sources for processing wafers up to 200

mm in diameter and are employed in volume manufacturing to achieve semiconductor design nodes requiring imaging at a resolution down to 90 nm.

The modular upgradeable design philosophy of the PAS 5500 product family has been further refined and applied in

the design of our TWINSCAN systems, which are the basis of our current and next-generation Step-and-Scan systems. TWINSCAN systems are equipped with i-line, KrF and ArF light sources for processing wafers up to 300 mm in diameter and are capable of

extending semiconductor shrink technology down to 38 nm and beyond with multiple patterning techniques. The dual-stage advantage of TWINSCAN immersion systems enables our customers to benefit from the process enhancement of immersion while

continuing to use familiar and proven technology. ASML’s TWINSCAN NXE platform is the industry’s first production platform for extreme ultraviolet lithography (EUVL), currently offering 22 nm resolution with conventional illumination and

18 nm with off-axis illumination as well as improved overlay and higher productivity.

In addition, we continuously develop and sell a range of product

options and enhancements, including the YIELDSTAR system, designed to increase semiconductor manufacturing productivity and improve imaging and overlay to optimize value of ownership over the entire lifecycle of our systems.

The above described products involve the use of 3TG minerals, which are necessary to the functionality and production of our products. For example, gold is

used in coating critical electronic connectors to enhance connectivity performance, totaling approximately 250 grams per TWINSCAN system. Each TWINSCAN system also contains approximately 1,500 grams of tin, used for welding electronic components on

printed circuit boards.

All 3TG minerals included in our systems are sourced as prefabricated component parts. ASML does not directly source 3TG minerals

as raw material. As a result, we are only able to determine whether the 3TG minerals included in our systems are derived from a Covered Country through information provided to us by our suppliers.

Reasonable Country of Origin Inquiry

ASML’s

reasonable country of origin inquiry (“RCOI”) was designed to determine whether any of the minerals that are necessary to the functionality and production of our products may have originated from the Covered Countries.

Our RCOI primarily consisted of conducting a supply-chain survey using the reporting template provided by the Electronic Industry Citizenship Coalition

(“EICC”) and the Global e-Sustainability Initiative (“GeSI”) (together, the “EICC/GeSI Conflict Minerals Reporting Template”). ASML surveyed 55 first-tier product suppliers of which the purchased product parts are

likely to contain 3TG minerals.

We also utilized resources provided by the Conflict-Free Sourcing Initiative (“CFSI”), including the

Conflict-Free Smelter Program (“CFSP”). The CFSP uses a third party audit firm to identify smelters and refiners that have systems in place to assure sourcing of only conflict-free materials, to provide additional country of origin

information.

Due Diligence

As a result of the RCOI, we have reason to believe that some of the 3TG minerals included in our systems are likely to have originated from the Covered

Countries. Therefore, we conducted supply chain due diligence on the source and chain of custody of the conflict minerals, in a manner consistent with the framework promulgated by the OECD and its Due Diligence Guidance for Responsible Supply

Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Guidance”). In our efforts to adhere to the OECD Guidance, we have taken the following actions:

| |

• |

|

Adopted a conflict minerals policy in 2013; |

| |

• |

|

Launched the ASML Conflict Minerals Project in 2013 which we continued in 2014; |

| |

• |

|

Employed a risk-based strategic approach towards due diligence to address relevant suppliers in 2013 which we continued in 2014; |

| |

• |

|

Informed suppliers on requirements, methods, and importance of supply chain due diligence to create awareness of our conflict minerals reporting obligations in 2013 which we continued in 2014; |

| |

• |

|

Engaged Suppliers using Standardized Reporting Tools; |

| |

• |

|

Utilized the EICC and CFSP resources to assess supplier responses in 2013 which we continued in 2014; |

| |

• |

|

Increased the response rate and quality of suppliers’ smelter surveys in 2014; |

| |

• |

|

Encouraged the success of the CFSP in 2014; and |

| |

• |

|

Compared RCOI results to information collected via conflict-free smelter validation programs in 2013 which we continued in 2014. |

These actions are each described in further detail below.

Adopted Conflict Minerals Policy

ASML adopted a conflict

minerals policy (the “Conflict Minerals Policy”) in 2013, committed to addressing the concern that certain minerals that are contained in our systems may contribute to the funding of military conflict and human rights violations in the

Covered Countries. Through this policy, we have encouraged our suppliers and sub-suppliers to responsibly source conflict minerals and their derivatives. This policy statement is available online at www.asml.com

Launched The ASML Conflict Minerals Project

To ensure

compliance with the Conflict Minerals Policy, in 2013 we designed and implemented the ASML conflict minerals project (the “Project”), which established internal management systems to support the newly-created conflict minerals project team

(the “Project Team”) in conducting due diligence in tracing the supply chain of conflict minerals in 2013. The Project Team continued its activities for the year 2014.

Employment of a Risk-Based Strategic Approach

The Project Team utilized a risk-based, phase-in strategic approach towards supplier awareness and due diligence, the full execution of which we estimate will

take a few years. Our risk-based phase-in approach focuses on introducing our suppliers to our expectations with respect to conflict minerals and conducting supply chain due diligence with selected first-tier product suppliers.

We examined our products, mineral usage, and direct spending volumes in 2012 to select those suppliers that provide us with the product parts most likely to

contain tin, tantalum, tungsten, or gold. This resulted in a targeted supplier population of 57 for the 2013 reporting. We surveyed 55 suppliers for the 2014 reporting.

Informing suppliers on requirements, methods, and importance of supply chain due diligence to create awareness.

In addition to adopting internal management systems and a company policy regarding conflict minerals, we have since 2013 communicated with suppliers in a

variety of ways to inform them about:

| |

• |

|

Our Conflict Minerals Policy; |

| |

• |

|

Dodd-Frank Act requirements and SEC rules relating to conflicts minerals; and |

| |

• |

|

The Project Team’s expectations. |

We informed suppliers of our reporting obligations with respect to

conflict minerals under Section 1502 of the Dodd-Frank Act and Form SD and referred suppliers to ASML Conflict Minerals Policy and additional information that described our approach to creating a sustainable supply chain.

In addition, in order to further prepare our suppliers, we published the Conflict Minerals Policy on ASML’s website for suppliers for their reference.

The Conflict Minerals Policy, due diligence approach, and supplier expectations have been conveyed to our supply chain via e-mail correspondence and

frequently asked questions (“FAQ”).

In an effort to encourage supplier compliance, we distributed a set of FAQs in a follow-up letter to our

suppliers in scope of this survey. We also elected to share the FAQs with our non-supplier peers to assist other companies in their compliance efforts. We held special information sessions as needed with individual first-tier suppliers upon their

request to foster awareness and greater understanding. We believe these sessions provided our suppliers with the necessary tools to enable them to trace their supply chains down to the smelter level.

In an effort to further encourage supplier compliance, ASML works in collaboration with several other technology OEM’s in the region of Eindhoven to

enlarge the pressure towards suppliers to implement conflict-free smelter programs such as the CFSI. Because the supplier-list of these OEMs is almost identical, these OEMs and local SME’s joined forces in Brainport Development encouraging

shared suppliers to utilize a conflict-minerals policy that attempts to map and trace the supply chain back to the smelter. Brainport Development works toward greater industry awareness by sharing supply-chain traceability information. Brainport

Development is a group of OEMs and SMEs from the region around Eindhoven in The Netherlands that also aims to strengthen the professional character and competitive position of the high-tech supply chain in the region.

Engaging Suppliers using Standardized Reporting Tools

Our Project Team sent formal inquiries for information to the selected first-tier suppliers. The inquiries included:

| |

• |

|

An overview of ASML’s disclosure requirements under the Securities Exchange Act of 1934 with respect to conflict minerals; |

| |

• |

|

Instructions for the suppliers to conduct their own supply chain due diligence to determine the country of origin of any conflict minerals in their products; and |

| |

• |

|

The standard EICC/GeSI Due Diligence Reporting Template, to identify smelters involved in their supply chains in 2014. |

Utilized the EICC and CFSP Resources to Assess Supplier Responses

Once the Project Team received completed EICC/GeSI Conflict Minerals Reporting Templates from our selected first-tier suppliers, we assessed the response

quality by verifying information accuracy and checking for inconsistencies. To ensure accuracy of the information provided, the Project Team compared the smelters and refiners identified by our direct suppliers against the list of smelter facilities

identified and/or designated as “conflict free” under the EICC and the CFSP’s lists for tantalum, tin, tungsten, and gold smelters. Any identified inconsistencies or inaccuracies were brought to the relevant suppliers’ attention

for correction.

Increased response rate and quality of suppliers’ smelter surveys

Because of our active participation in the Brainport Development program, individual follow-up on suppliers survey results and sharing of FAQs, we are able to

report a response rate of 98% of the 55 suppliers that were surveyed in 2014. Based on detailed assessment of the reports returned, we believe that the quality of the reports can still be improved. A majority of the suppliers surveyed are not able

to map and trace their supply chains back to the smelters used or to otherwise identify smelters supplying 3TG minerals. We will bring this fact back to the relevant suppliers’ attention.

Encouraged the success of the Conflict Free Smelter Program

To aid in the industry-wide concerns regarding conflict minerals, in addition to working with our own suppliers, we are also participating in initiatives led

by the EICC and GeSI. In 2013, ASML became a full member of the EICC. These organizations support information sharing on suppliers, including the identification and conflict-free status of 3TG smelters and refiners.

Through our membership and our participation in both the EICC and the CFSI, we continue to support the development of the CFSP, which aims for certification

of smelters and promotion of responsible sourcing from the Covered Countries, such that the legitimate miners involved those countries do not suffer. Since the start of the CFSI, members of the Project Team have regularly attended the various CFSI

Workshops organized by the EICC, focusing on in-region traceability and certification programs, practical aspects of conflict minerals legislation and reporting, and compliance best practices.

As of February 2015, the CFSI verified the identities of 297 smelters world-wide, approximately 143 of which are

certified. As a result of our due diligence efforts, we can report that we have identified over 278 legitimate smelters verified by the CFSI within our supply chain, 141 of which are certified as “DRC Conflict-Free.”

Compared RCOI results to information collected via conflict-free smelter validation programs

The majority of the suppliers surveyed, delivered a declaration in the CMRT format, including a list of smelters they could identify. As a result of the

examination, however, we can report, that the quality of the declarations can still be improved. For example, we have noticed inconsistencies in several suppliers’ declarations between the smelter information provided and information provided

by the CFSP on those smelters. These inconsistencies will be brought to the relevant suppliers’ attention.

Due Diligence Results

Due to the incomplete nature of the data available from our supply chain, a direct result of the 3TG supply chain complexity and the limited number of

certified conflict free smelters for all conflict minerals, we are unable to determine the precise origin of many of the 3TG minerals included in our products.

Further Risk Mitigation and Improved Due Diligence

In an

effort to improve our due diligence process and to further increase the transparency of our mineral supply chain, ASML anticipates undertaking the following steps:

| |

• |

|

Increase the quality of suppliers’ smelter surveys through various techniques, including educational trainings, the Brainport Development program and individual supplier support; |

| |

• |

|

Actively encourage the success of the CFSP via increased smelter identification, outreach and certification through our continued membership with and support of the EICC and the CFSI. ASML will provide these initiatives

with frequently mentioned smelter names by its suppliers that are not yet engaged by CFSI, which ASML expects will result in a more up to date conflict-free smelter list; |

| |

• |

|

Institute a yearly program to select relevant suppliers that provide us with the product parts most likely to contain 3TGs by examining our products, mineral usage, and direct spending volumes to select the relevant

suppliers that provide us with the product parts most likely to contain 3TGs minerals. We will evaluate the selection of suppliers based on 2014 purchasing data and due-diligence results for our reporting for the year ended December 31, 2015.

|

Website Availability

This Conflict Minerals Report is publicly available at: www.asml.com.

Forward Looking Statements

This document contains

statements that are forward-looking, including statements relating to our compliance efforts, our plans to take additional actions or to implement additional policies or procedures, including plans with respect to our due diligence efforts to

determine the origin of certain minerals contained in our products, our EICC and CFSI membership and our plans to work to improve the CFSP. You can generally identify these statements by the use of words like “may”, “will”,

“could”, “should”, “project”, “believe”, “anticipate”, “expect”, “plan”, “estimate”, “forecast”, “potential”, “intend”,

“continue” and variations of these words or comparable words.

Forward-looking statements do not guarantee future performance and involve risks

and uncertainties. These risks and uncertainties include, our reporting obligations under the conflict minerals rules, our ability to implement certain processes and policies, our ability to obtain information from our suppliers, and other risks

indicated in the risk factors included in ASML’s Annual Report on Form 20-F and its other filings with the US Securities and Exchange Commission. These forward-looking statements are made only as of

the date of this document. ASML does not undertake to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise.

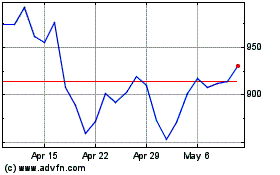

ASML Holding NV (NASDAQ:ASML)

Historical Stock Chart

From Mar 2024 to Apr 2024

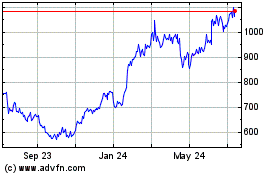

ASML Holding NV (NASDAQ:ASML)

Historical Stock Chart

From Apr 2023 to Apr 2024