UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

Amkor Technology, Inc.

(Exact name of registrant as specified in its charter)

|

| | | |

Delaware | 000-29472 | 23-1722724 |

(State or other jurisdiction of incorporation or organization) | (Commission File Number) | (IRS Employer Identification No.) |

| | |

2045 East Innovation Circle, Tempe, AZ | 85284 |

(Address of principal executive offices) | (Zip Code) |

| | |

Gil C. Tily | (480) 821-5000 |

(Name and telephone number, including area code, of the person to contact in connection with this report) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

[X] Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014.

Section 1 - Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

Amkor conducted in good faith, a Reasonable Country of Origin Inquiry (RCOI) on the source of its Conflict Minerals for 2014. Our RCOI was designed to determine whether the Conflict Minerals (tantalum, tin, tungsten, and gold) we used when performing semiconductor packaging services originated from the Democratic Republic of the Congo or an adjoining country (the “Covered Countries”) or are from recycled or scrap sources.

We conducted our RCOI with our direct suppliers using the Conflict Minerals Reporting Template (CMRT), a supply chain survey tool provided by the Conflict-Free Sourcing Initiative (CFSI), an industry group that works to address Conflict Minerals issues within supply chains. The CMRT requests direct suppliers to identify the smelters, refiners, and countries of origin of the Conflict Minerals in their products. We relied primarily on responses received from our direct suppliers to identify sources of Conflict Minerals and information provided by the CFSI.

Based on the responses to our RCOI, we know or have reason to believe that a portion of the Conflict Minerals we use originated or may have originated from the Covered Countries or may not be solely from recycled or scrap sources.

In accordance with Rule 13p-1 under the Securities Exchange Act of 1934, Amkor has filed this Specialized Disclosure Form (Form SD) and the attached Conflict Minerals Report. Both reports are available on the “Investors” tab of www.amkor.com, under “SEC filings”. This Form SD and Exhibit 1.01 contain references to our website. The information on this website is not incorporated by reference into this Form SD or Exhibit 1.01.

Item 1.02 Exhibit

As an exhibit to this Form SD, we provide the Conflict Minerals Report as required by Item 1.01.

Section 2 - Exhibits

Item 2.01 Exhibits

Exhibit 1.01 - Conflict Minerals Report, for the reporting period January 1, 2014 to December 31, 2014, as required by Items 1.01 and 1.02 of this Form.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

(Registrant)

|

| | |

/s/ Gil C. Tily | | May 22, 2015 |

Gil C. Tily, Executive Vice President, Chief Administrative Officer, General Counsel and Corporate Secretary | | Date |

Exhibit 1.01

Conflict Minerals Report of Amkor Technology, Inc.

All information contained in this Conflict Minerals Report (the “Report”), other than statements of historical fact, constitute forward-looking statements within the meaning of federal securities laws. These forward-looking statements involve a number of risks, uncertainties, assumptions and other factors including, among other things, our customers’ requirements to use certain suppliers, our suppliers’ responsiveness and cooperation with our due diligence efforts, our ability to implement improvements in our conflict minerals program and our ability to identify and mitigate related risks in our supply chain. For a more complete discussion of these and other risk factors, see our other filings with the Securities and Exchange Commission (“SEC”), including our Annual Report on Form 10-K for the year ended December 31, 2014. We undertake no obligation to review or update any forward-looking statements to reflect events or circumstances occurring after filing this Report with the SEC.

This Conflict Minerals Report of Amkor Technology, Inc. for calendar year 2014 was prepared in accordance with Rule 13p-1 under the Securities Exchange Act of 1934.

Business Overview

Amkor is one of the world’s leading providers of outsourced semiconductor packaging and test services. Packaging is the processing of bare die, a small block of semiconducting material on which a given functional circuit is fabricated, to facilitate electrical connections, heat dissipation and protection of the die. Some of the materials we use when providing packaging services contain tantalum, tin, tungsten, or gold (“Conflict Minerals”). Test services involve checking that a packaged die meets its design and performance specifications and do not involve the use of Conflict Minerals.

The mineral supply chain that provides us with Conflict Minerals is divided into upstream and downstream entities. An upstream entity is from the mine to the smelter or refiner and includes miners, local traders, exporters from the country of mineral origin, international concentrate traders, mineral reprocessors, smelters, and refiners. A downstream entity is within the minerals supply chain from when the mineral leaves the smelter or refiner to when it arrives at the retailer and includes metal traders and exchanges, component manufacturers, product manufacturers, original equipment manufacturers, and retailers.

Amkor is a downstream entity and is typically several tiers removed from the smelter or refiner and mineral origin. We have limited visibility beyond our direct suppliers to entities within the supply chain. Therefore, we rely principally on our direct suppliers to provide us with sourcing information.

Due Diligence Overview

We undertook due diligence on the source and chain of custody of the Conflict Minerals we use when providing packaging services. We conducted a significant portion of our due diligence using tools and relying on information provided by the Conflict-Free Sourcing Initiative (CFSI), an industry group that works to address Conflict Minerals issues within supply chains. One CFSI tool we used was the Conflict Minerals Reporting Template (CMRT), which facilitates the collection of information on the source of Conflict Minerals. We also relied on information from the Conflict-Free Smelter Program (CFSP), a voluntary initiative managed by the CFSI in which an independent third party audits the procurement activities of a smelter or refiner to determine, with reasonable confidence, that the minerals it processes originated from conflict-free sources.

Due Diligence Design

We designed our due diligence to conform to an internationally recognized due diligence framework, the Organisation for Economic Co-operation and Development (OECD), Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, Second Edition, 2013 and related supplements on Tin, Tantalum and Tungsten and on Gold (collectively, “OECD Framework”).

Due Diligence Performed

The OECD Framework provides a five-step framework for risk-based due diligence in the mineral supply chain. Using this framework, we list below the actions taken to exercise due diligence on the source of Conflict Minerals we used when providing packaging services.

Step 1 - Establish Strong Management Systems

| |

• | Adopted and published a Conflict Minerals Policy, stating our goal to achieve a conflict-free supply chain, on the “About Us” tab of www.amkor.com. |

| |

• | Assembled an internal team to implement our Conflict Minerals Policy, which included members from the Procurement, Legal, Internal Audit and Quality Assurance teams. |

| |

• | Established processes and procedures to meet the requirements of our Conflict Minerals Policy. |

| |

• | Required our direct suppliers to undertake due diligence to achieve a conflict-free supply chain. |

| |

• | Instituted a records retention practice for records related to the sourcing of Conflict Minerals. |

| |

• | Maintained our existing grievance system where stakeholders can raise a question or make a report on ethical or legal issues, including issues relating to Conflict Minerals. |

| |

• | Obtained an independent assessment of the current state of our Conflict Minerals Management System for alignment with the OECD Framework. |

Step 2 - Identify and Assess Risks in the Supply Chain

| |

• | Conducted a supply chain survey of our direct suppliers using the CMRT to identify the smelters, refiners and/or mine of origin of Conflict Minerals. |

| |

• | Compared smelters, refiners and/or mine of origin identified by our direct suppliers against the list of smelters, refiners and mineral sourcing information that have received a “conflict-free” designation by the CFSP. |

| |

• | Performed additional due diligence on a portion of our direct suppliers, including on-site reviews of documentation and procedures, to evaluate the reasonableness of responses received and alignment with the OECD Framework. |

Step 3 - Design and Implement a Strategy to Respond to Identified Risks

| |

• | Prepared a risk management plan designed to mitigate the risk that our direct suppliers do not meet our expectations to achieve a conflict-free supply chain. |

| |

• | Conducted training and held periodic communications with our direct suppliers to increase awareness of our goal to achieve a conflict free supply chain and to reduce the risk of inaccurate information received from our suppliers. |

| |

• | Contacted a portion of smelters and refiners within our supply chain to encourage them to participate in the CFSP or industry equivalent. Our outreach efforts included on-site visits with select smelters and meetings with industry associations. |

Step 4 - Carry Out Independent Third-party Audits of Smelter/Refiner’s Due Diligence Practices

| |

• | Maintained our membership in the CFSI, an industry group that has implemented the CFSP. As a member, we have relied on the results of the CFSP to provide smelter, refiner, and mineral sourcing information on the Conflict Minerals we used when providing packaging services. |

Step 5 - Report Annually on Supply Chain Due Diligence

| |

• | Published our supply chain due diligence within our 2014 Form SD and Conflict Minerals Report, which is located on the “Investors” tab of www.amkor.com, under “SEC filings”. |

Due Diligence Results

The results of our due diligence indicates that the sources of Conflict Minerals are (1) from recycled or scrap materials, (2) from within the Democratic Republic of the Congo or adjoining countries (the “Covered Countries”), (3) from outside the Covered Countries or (4) unknown. We received responses from all of our direct suppliers subject to our supply chain survey for 2014. Collectively, their responses listed 107 known smelters and refiners within their supply chains. Of the 107 smelters and refiners identified, 94 have been designated as Conflict Free under the CFSP.

The following tables list, to the extent known, the population of smelters, refiners, and origin of Conflict Minerals within our supply chain for 2014. Our efforts to determine this population are described above under the caption “Due Diligence Performed.” The information presented is derived from information provided by our direct suppliers and the CFSP.

|

| | |

Smelters and Refiners Processing Conflict Minerals, to the Extent Known |

Mineral | Smelter or Refiner Name | Country Location |

Gold | Aida Chemical Industries Co. Ltd. | Japan |

Gold | Allgemeine Gold-und Silberscheideanstalt A.G. | Germany |

Gold | AngloGold Ashanti Córrego do Sítio Minerção | Brazil |

Gold | Argor-Heraeus SA | Switzerland |

Gold | Asahi Pretec Corporation | Japan |

Gold | Asaka Riken Co Ltd | Japan |

Gold | Aurubis AG | Germany |

Gold | CCR Refinery – Glencore Canada Corporation | Canada |

Gold | The Refinery of Shandong Gold Mining Co. Ltd | China |

Gold | Dowa | Japan |

Gold | Eco-System Recycling Co., Ltd. | Japan |

Gold | Heraeus Ltd. Hong Kong | Hong Kong |

Gold | Heraeus Precious Metals GmbH & Co. KG | Germany |

Gold | Ishifuku Metal Industry Co., Ltd. | Japan |

Gold | Johnson Matthey Ltd | Canada |

Gold | Johnson Matthey Inc. | United States |

Gold | JX Nippon Mining & Metals Co., Ltd. | Japan |

Gold | Kennecott Utah Copper LLC | United States |

Gold | Kojima Chemicals Co., Ltd | Japan |

Gold | LS-NIKKO Copper Inc. | South Korea |

Gold | Materion | United States |

Gold | Matsuda Sangyo Co., Ltd. | Japan |

Gold | Metalor Technologies (Hong Kong) Ltd | Hong Kong |

Gold | Metalor Technologies SA | Switzerland |

Gold | Metalor USA Refining Corporation | United States |

Gold | Mitsubishi Materials Corporation | Japan |

Gold | Mitsui Mining and Smelting Co., Ltd. | Japan |

Gold | Nihon Material Co. LTD | Japan |

Gold | Ohio Precious Metals, LLC | United States |

Gold | Ohura Precious Metal Industry Co., Ltd | Japan |

Gold | Pamp SA | Switzerland |

Gold | Rand Refinery (Pty) Ltd | South Africa |

Gold | Republic Metals Corporation | United States |

Gold | Royal Canadian Mint | Canada |

Gold | Sempsa Joyería Platería Sa | Spain |

Gold | Shandong Zhaojin Gold & Silver Refinery Co. Ltd | China |

Gold | Solar Applied Materials Technology Corp. | Taiwan |

Gold | Sumitomo Metal Mining Co., Ltd. | Japan |

Gold | Tanaka Kikinzoku Kogyo K.K. | Japan |

Gold | Tokuriki Honten Co., Ltd | Japan |

Gold | Umicore SA Business Unit Precious Metals Refining | Belgium |

Gold | United Precious Metal Refining, Inc. | United States |

Gold | Valcambi SA | Switzerland |

Gold | Western Australian Mint trading as The Perth Mint | Australia |

|

| | |

Smelters and Refiners Processing Conflict Minerals, to the Extent Known |

Mineral | Smelter or Refiner Name | Country Location |

Gold | Yamamoto Precious Metal Co., Ltd. | Japan |

Gold | Yokohama Metal Co Ltd | Japan |

Tantalum | F&X Electro-Materials Ltd. | China |

Tantalum | Global Advanced Metals Boyertown | United States |

Tantalum | H.C. Starck Co., Ltd. | Thailand |

Tantalum | H.C. Starck GmbH Goslar | Germany |

Tantalum | H.C. Starck GmbH Laufenburg | Germany |

Tantalum | H.C. Starck Hermsdorf GmbH | Germany |

Tantalum | H.C. Starck Inc. | United States |

Tantalum | H.C. Starck Ltd. | Japan |

Tantalum | H.C. Starck Smelting GmbH & Co.KG | Germany |

Tantalum | Mitsui Mining & Smelting | Japan |

Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. | China |

Tantalum | Solikamsk Magnesium Works OAO | Russian Federation |

Tantalum | Taki Chemicals | Japan |

Tantalum | Ulba | Kazakhstan |

Tin | Alpha | United States |

Tin | China Tin Group Co., Ltd. | China |

Tin | Cooper Santa | Brazil |

Tin | PT DS Jaya Abadi | Indonesia |

Tin | CV United Smelting | Indonesia |

Tin | EM Vinto | Bolivia |

Tin | Fenix Metals | Poland |

Tin | Minsur | Peru |

Tin | Gejiu Non-Ferrous Metal Processing Co. Ltd. | China |

Tin | Magnu's Minerais Metais e Ligas LTDA | Brazil |

Tin | Malaysia Smelting Corporation (MSC) | Malaysia |

Tin | Metallo Chimique | Belgium |

Tin | Mineração Taboca S.A. | Brazil |

Tin | Mitsubishi Materials Corporation | Japan |

Tin | O.M. Manufacturing Philippines, Inc. | Philippines |

Tin | OMSA | Bolivia |

Tin | PT Artha Cipta Langgeng | Indonesia |

Tin | PT Babel Inti Perkasa | Indonesia |

Tin | PT Bangka Tin Industry | Indonesia |

Tin | PT Bukit Timah | Indonesia |

Tin | PT Eunindo Usaha Mandiri | Indonesia |

Tin | PT Mitra Stania Prima | Indonesia |

Tin | PT Prima Timah Utama | Indonesia |

Tin | PT Refined Bangka Tin | Indonesia |

Tin | PT Sariwiguna Binasentosa | Indonesia |

Tin | PT Stanindo Inti Perkasa | Indonesia |

Tin | PT Tambang Timah | Indonesia |

Tin | PT Timah (Persero), Tbk | Indonesia |

|

| | |

Smelters and Refiners Processing Conflict Minerals, to the Extent Known |

Mineral | Smelter or Refiner Name | Country Location |

Tin | PT Tinindo Inter Nusa | Indonesia |

Tin | Rui Da Hung | Taiwan |

Tin | Soft Metais, Ltda. | Brazil |

Tin | Thaisarco | Thailand |

Tin | White Solder Metalurgia e Mineração Ltda. | Brazil |

Tin | Yunnan Chengfeng Non-ferrous Metals Co., Ltd. | China |

Tin | Yunnan Tin Company, Ltd. | China |

Tungsten | Chongyi Zhangyuan Tungsten Co., Ltd. | China |

Tungsten | Ganzhou Huaxing Tungsten Products Co., Ltd. | China |

Tungsten | Ganzhou Seadragon W & Mo Co., Ltd. | China |

Tungsten | Global Tungsten & Powders Corp. | United States |

Tungsten | H.C. Starck GmbH | Germany |

Tungsten | Hunan Chunchang Nonferrous Metals Co., Ltd. | China |

Tungsten | Japan New Metals Co., Ltd. | Japan |

Tungsten | Kennametal Huntsville | United States |

Tungsten | Tejing (Vietnam) Tungsten Co., Ltd. | Vietnam |

Tungsten | Wolfram Bergbau und Hütten AG | Austria |

Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. | China |

Tungsten | Xiamen Tungsten Co., Ltd. | China |

|

| | |

Countries of Origin for Conflict Minerals, to the Extent Known |

Angola | Guyana | Republic of Congo |

Argentina | Hungary | Russia |

Australia | India | Rwanda |

Austria | Indonesia | Sierra Leone |

Belgium | Ireland | Singapore |

Bolivia | Israel | Slovakia |

Brazil | Japan | South Africa |

Burundi | Kazakhstan | South Korea |

Canada | Kenya | South Sudan |

Central African Republic | Laos | Spain |

Chile | Luxembourg | Suriname |

China | Madagascar | Switzerland |

Columbia | Malaysia | Taiwan |

Cote D’Ivoire | Mongolia | Tanzania |

Czech Republic | Mozambique | Thailand |

Democratic Republic of Congo | Myanmar | Uganda |

Djibouti | Namibia | United Kingdom |

Egypt | Netherlands | United States of America |

Estonia | Nigeria | Vietnam |

Ethiopia | Peru | Zambia |

France | Portugal | Zimbabwe |

Germany | | |

Due Diligence Improvements

We plan to undertake the following steps during the next compliance period to mitigate the risk that our Conflict Minerals benefit armed groups:

| |

• | Continue our engagement with our direct suppliers with additional training and periodic communications. |

| |

• | Maintain our efforts to identify the number of smelters and refiners within our supply chain by evaluating the information received from our direct suppliers and comparing it with revised information published by the CFSI. |

| |

• | Contact a portion of our smelters and refiners directly to encourage them to participate in the CFSP or industry equivalent. |

| |

• | Obtain an independent assessment of the current state of our Conflict Minerals Management System for alignment with the OECD Framework. |

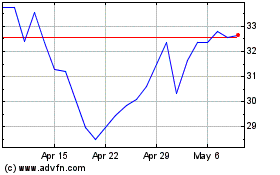

Amkor Technology (NASDAQ:AMKR)

Historical Stock Chart

From Mar 2024 to Apr 2024

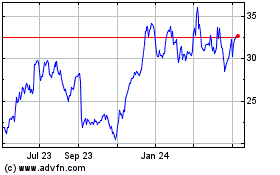

Amkor Technology (NASDAQ:AMKR)

Historical Stock Chart

From Apr 2023 to Apr 2024