By Ted Mann

Jet-engine maker Pratt & Whitney had a problem this summer,

one familiar to anyone who has assembled a do-it-yourself bookcase:

Not all the parts were in the box.

Production on the company's engines--including a new generation

spawned by a $10 billion investment--ground almost to a halt for

nearly a month in August as problems with the launch of a

custom-built UPS facility for engine parts cascaded into a

crisis.

Pratt, a unit of United Technologies Corp., had contracted with

United Parcel Service Inc. in an effort to streamline its supply

chain as it prepared to ramp up manufacturing. Pratt has a backlog

of more than 7,000 orders for the more fuel-efficient commercial

engines, and plans to increase annual output to more than 500 by

2018 from dozens this year.

UPS said last year it would set up a logistics center in

Londonderry, N.H., to take in parts from Pratt's suppliers, package

them into kits holding about 8,000 parts, and ship them to Pratt

factories for assembly by company's machinists.

But the 130-person logistics facility was beset by problems

after it opened in July, said people familiar with the operation,

slowing assembly to a crawl. Some engine kits arrived at Pratt's

engine centers in Middletown, Conn., and West Palm Beach, Fla.,

without all the required require parts.

The union for the machinists that assemble Pratt's engines said

some parts arrived dirty and damaged. That forced workers to

scrounge together parts for a single engine from multiple kits,

ultimately slowing downassembly for weeks this summer.

"Kits are coming in with wrong parts, and some of the parts

don't even fit in the allocated slot! It's almost like trying to

put a square peg into a round hole!," a union representative wrote

in a newsletter to members last month.

After the August disruption, Pratt says parts are now flowing as

intended through the logistics center, and that engine output is

back to normal.

"UPS personnel have worked closely with the team at Pratt &

Whitney to resolve initial implementation issues, and material is

now flowing to assembly sites at scheduled production volume," a

UPS spokesman said.

Danny DiPerna, Pratt's senior vice president for engineering and

operations, acknowledged "a temporary interruption of material flow

to our factories" this summer, but said the company chalks the

problems up to growing pains.

After the problems emerged, high-rankingPratt executives spent

weeks on the ground in Londonderry, training UPS workers who were

unfamiliar with jet-engine parts and working out kinks in the

companies' inventory software.

The incident highlights the pressure Pratt, which accounts for

22% of United Technologies's $65 billion in annual sales, is under

to keep its operations running smoothly as it begins its engine

ramp-up--and how efforts to streamline a supply chain can

backfire.

"People always ask, 'What's the one thing that keeps you up at

night?' " United Technologies Chief Executive Greg Hayes said last

month. "It's the ramp. The technology, I'm very confident we've got

that right. But you're only as good as your worst supplier. When

you've got 8,000 parts in an engine, one of those parts aren't

there, you're not building an engine."

By turning over its logistics to UPS, Pratt had hoped that it

would eliminate low-value work for its labor force, and avoid

holding extensive inventory on its own books, Mr. Hayes said. The

company will use the new logistics system for all of its engine

models, including for the new F-35 fighter for the U.S. Air

Force.

With its older engines in decline and the new design requiring a

huge increase in manufacturing, Pratt handed off management of

parts and inventory to a highly automated UPS warehouse that it

believes will better cope with a much higher rate of production,

Pratt's Mr. DiPerna said.

"In the grand scheme of things, this took a few more weeks that

we had planned," he said, but the facility will support Pratt's

production for decades.

According to a person familiar with the matter, the companies

regard the union's complaints as sour grapes from labor leaders

whose members had been usurped by UPS's nonunion workforce. Union

officials didn't respond to requests for comment.

The New Hampshire missteps are a stumble for UPS, which has been

building out its supply-chain service business in recent years as

it copes with pressures in its traditional delivery business. While

supply chain is still a small part of UPS's overall business,

making up only about 15% of revenues when combined with the

company's freight division, it is one that executives have touted

as a road to growth and part of the delivery giant's core

business.

Laura Stevens contributed to this article.

Write to Ted Mann at ted.mann@wsj.com

Subscribe to WSJ: http://online.wsj.com?mod=djnwires

(END) Dow Jones Newswires

October 01, 2015 20:26 ET (00:26 GMT)

Copyright (c) 2015 Dow Jones & Company, Inc.

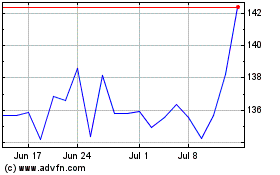

United Parcel Service (NYSE:UPS)

Historical Stock Chart

From Mar 2024 to Apr 2024

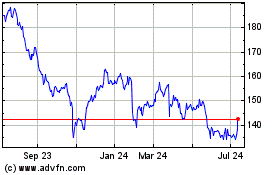

United Parcel Service (NYSE:UPS)

Historical Stock Chart

From Apr 2023 to Apr 2024