GM Loosens Terms for Some Suppliers

June 17 2016 - 2:30PM

Dow Jones News

General Motors Co. will allow roughly 400 parts makers providing

components for new vehicles in Mexico and Brazil to periodically

renegotiate contracts, an unusual break for suppliers facing

financial pressures from rising materials costs and unstable

foreign currencies.

At least once a year, the parts makers can now renegotiate terms

when hit by unexpected economic pressures, such as currency

fluctuations, GM's purchasing chief said Friday. The move comes as

GM prepares to invest $5 billion over the next decade to develop a

new group of Chevrolet vehicles to sell in Mexico and Brazil

starting with the 2019 model year. Those vehicles are also set to

be sold in India and China.

The concession is unusual for GM, which historically fights for

ironclad contracts that squeeze suppliers dependent on them for

business. But the Detroit auto maker, which spends $85 billion

annually as the world's largest car-parts purchaser, also needs to

ensure suppliers don't suffer too much financial strain to avoid

production disruptions.

Economic turmoil in Brazil, for instance, lessens GM's leverage

at a time when the auto maker wants to roll out cars there. "There

is a lot of hesitancy by suppliers to invest there," said Steve

Kiefer, GM's purchasing chief, in an interview. "But we are focused

on the Brazil market, and we want to work together with our

suppliers to make that work."

Mr. Kiefer has been exploring new strategies for dealing with

suppliers since taking the purchasing helm at GM in November 2014.

A former employee for three decades at Delphi Automotive PLC, one

of GM's largest suppliers, Mr. Kiefer is allowing longer-term

contracts and consulting more with parts makers during early design

stages for new vehicles.

He is also forging pacts that allow companies providing

driverless-car technologies—such as adaptive cruise control and

collision-warning systems—to supply competing car makers and

maintain intellectual-property rights in exchange for giving GM

first crack at their new technologies.

"What we have today are fixed, very rigid contracts and we tell

the suppliers don't bother us with the details," Mr. Kiefer said.

"On a very narrow band of business, that approach works. But when

you have moving raw-material costs and currency rates, you find

yourself spending too much time fighting over that.

"What we are trying to do here is take that all off the table by

adopting a simple formula that is more predictable and allows both

sides to share in the ups and downs of those costs."

GM's reputation among suppliers has long trailed competitors,

with the Detroit auto maker finishing in fourth place in a recent

survey of working relations. Toyota Motor Corp. of Japan took the

top spot in the survey.

"I have never heard anything like this before," said John Henke,

president of Birmingham, Mich.-based Planning Perspectives Inc.,

referring to GM allowing parts makers to renegotiate contracts. "It

will be prudent for the other auto makers to quickly follow since

about 70% of their revenue is spent on suppliers." Mr. Henke's firm

conducted the survey of supplier working relations by polling 647

salespeople from 492 top suppliers that negotiate with auto

makers.

Write to Jeff Bennett at jeff.bennett@wsj.com

(END) Dow Jones Newswires

June 17, 2016 14:15 ET (18:15 GMT)

Copyright (c) 2016 Dow Jones & Company, Inc.

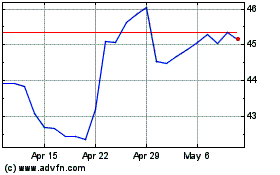

General Motors (NYSE:GM)

Historical Stock Chart

From Mar 2024 to Apr 2024

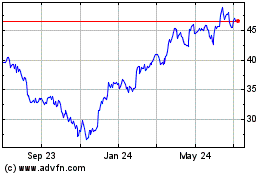

General Motors (NYSE:GM)

Historical Stock Chart

From Apr 2023 to Apr 2024