UNITED STATES SECURITIES AND

EXCHANGE COMMISSION

Washington, D.C. 20549

Form SD

SPECIALIZED DISCLOSURE REPORT

Marvell

Technology Group Ltd.

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| Bermuda |

|

0-30877 |

|

77-0481679 |

| (State or other jurisdiction of

incorporation or organization) |

|

(Commission File No.) |

|

(I.R.S. Employer Identification No.) |

Canon’s Court

22 Victoria Street

Hamilton HM 12, Bermuda

(Address of principal executive offices)

Tom Savage

Vice

President, Legal

and Governmental Policy,

General Counsel

(408) 222-9753

(Name

and telephone number, including area code, of

person to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this report

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period January 1, 2014 to December 31, 2014. |

Item 1.01. Conflict Minerals Disclosure and Report.

Conflict Minerals Disclosure

A copy of

the Conflict Minerals Report of Marvell Technology Group Ltd. (the “Company”) for the reporting period January 1, 2014 to December 31, 2014 is filed as Exhibit 1.01 to this specialized disclosure report on Form SD and is also

available at the Company’s website at www.marvell.com under the heading “Investor Relations - Corporate Governance and Social Responsibility.”

Item 1.02. Exhibit.

As noted in

Item 1.01, the Company is filing its Conflict Minerals Report as Exhibit 1.01 to this report.

Item 2.01. Exhibit.

The following exhibit is filed as a part of this report:

|

|

|

|

Exhibit No. |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report of Marvell Technology Group Ltd. for the reporting period January 1, 2014 to December 31, 2014. |

2

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by

the duly authorized undersigned.

Date: May 29, 2015

|

|

|

| Marvell Technology Group Ltd. |

|

|

| By: |

|

/s/ Sukhi Nagesh |

|

|

Sukhi Nagesh |

|

|

Interim Chief Financial Officer |

3

EXHIBIT INDEX

|

|

|

|

Exhibit No. |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report of Marvell Technology Group Ltd. for the reporting period January 1, 2014 to December 31, 2014. |

4

Exhibit 1.01

MARVELL TECHNOLOGY GROUP LTD.

CONFLICT MINERALS REPORT

(For the reporting period January 1, 2014 to December 31, 2014)

This Conflict Minerals Report (this “Report”) of Marvell Technology Group Ltd. has been prepared pursuant to Rule 13p-1 and Form SD promulgated under the Securities Exchange Act of 1934 (collectively, the “Rule”) for the reporting period January 1, 2014 to December 31, 2014.

The Rule imposes certain reporting obligations on Securities and Exchange Commission (“SEC”) registrants whose manufactured products

contain certain minerals that are necessary to the functionality or production of their products. The specified minerals, which are collectively referred to in this Report as “Conflict Minerals,” are gold, columbite-tantalite (coltan),

cassiterite and wolframite, including their derivatives, which the SEC has currently limited to tantalum, tin and tungsten. The “Covered Countries” for purposes of the Rule and this Report are the Democratic Republic of the Congo, the

Republic of the Congo, Central African Republic, South Sudan, Uganda, Rwanda, Burundi, Tanzania, Zambia and Angola. For purposes of this Report, references to “Marvell,” “we,” “us,” “our” or the

“Company” mean Marvell Technology Group Ltd. and its consolidated subsidiaries.

To comply with the Rule, we conducted due

diligence on the origin, source and chain of custody of the Conflict Minerals that were necessary to the functionality or production of the products that we manufactured or contracted to manufacture to ascertain whether these Conflict Minerals

originated in a Covered Country and financed or benefited armed groups (as defined in Section 1, Item 1.01(d)(2) of Form SD) in any of these countries.

Pursuant to SEC guidance issued April 29, 2014 and the SEC order issued May 2, 2014, Marvell is not required to describe any of its

products as “DRC conflict free” (as defined in Section 1, Item 1.01(d)(4) of Form SD), “DRC conflict undeterminable” (as defined in Section 1, Item 1.01(d)(5) of Form SD) or “having not been found to

be “DRC conflict free,” and therefore makes no conclusion in this regard in the report presented herein.

I. Marvell and Its Products

We are a fabless provider of high-performance, application-specific standard semiconductor products. Our core strength is the

development of complex system-on-a-chip (“SoC”) and System-in-a-Package (SiP”) devices, leveraging our extensive portfolio of intellectual property in the areas of analog, mixed-signal, digital signal processing and embedded and

stand-alone integrated circuits. We also develop platforms that we define as integrated hardware along with software that incorporates digital computing technologies designed and configured to provide an optimized computing solution.

Our current product portfolio principally addresses three broad end markets: mobile and wireless, storage and networking.

Mobile and Wireless Products. We offer a broad range of products for the mobile and wireless end market, including integrated

communications and applications processors, thin modem devices, connectivity solutions and mobile computing products.

Storage

Products. We offer a broad range of integrated data storage products that operate across all major technologies. Our storage products include: hard disk drive controllers, solid-state drive controllers, and integrated SoCs for storage

markets.

Networking Products. We offer several families of products supporting the build-out of new network architectures

for residential, enterprise and service provider networks. These products include a variety of platform and SoC solutions, as well as switches, transceivers and other connectivity products.

Other Products. We also offer SoC products that power laser and ink jet printers

and multi-function peripherals, as well as our smart home product portfolio, including SoCs and other products designed to enable the next generation of connected consumer platforms.

Products Covered by this Report. All of the products contracted by the Company to be manufactured for which manufacturing was

completed during calendar year 2014 consisted of integrated circuits or products incorporating integrated circuits and contained small amounts of gold, tantalum, tin and tungsten. These Conflict Minerals are necessary to the functionality or

production of each of our integrated circuit products and components. For purposes of this Report, therefore, “products” refers to the products in the product categories listed above for which the manufacturing was completed during

calendar year 2014, and “suppliers” refers to our product suppliers.

II. Manufacturing and Supply Chain

We employ a “fabless” model for the manufacture, assembly and testing of our integrated circuits. We do not own or operate our own

foundries or manufacturing facilities. We outsource our integrated circuit manufacturing to third-party foundries, primarily in Asia. We also outsource all product assembly, packaging and testing of our products to several assembly and test

subcontractors in Asia.

As a result of our fabless model, we are a downstream actor in a complex supply chain. Our semiconductor products

typically contain many parts obtained from a global network of direct suppliers. Furthermore, we often do not have meaningful leverage over upstream actors in the supply chain, as there are multiple tiers of suppliers between us and the ultimate

sources of the raw materials used in the manufacture of our integrated circuit products and our other products that incorporate integrated circuits. Raw materials purchased by our direct and indirect suppliers contain gold, tantalum, tin and

tungsten obtained from smelters and refiners that, in turn, source those minerals from traders and mines in various countries. Because we do not purchase materials directly from any of these processing facilities, we have relied on our direct

suppliers, and on information available from industry sources, for purposes of this Report.

III. Reasonable Country of Origin Inquiry

We requested that our direct suppliers complete in full the Electronics Industry Citizenship Coalition (“EICC”)–Global e-Sustainability Initiative (“GeSI”) Conflict Minerals Reporting Template (the “CMRT”). The CMRT is designed to request from suppliers sufficient information regarding such suppliers’

practices with respect to the sourcing of Conflict Minerals to enable Marvell to comply with its requirements under the Rule.

Based on

the results of our reasonable country of origin inquiry (“RCOI”), we are unable to determine whether the Conflict Minerals present in our products originate in the Covered Countries. We are therefore required by the Rule to file with the

SEC a Form SD and a Conflict Minerals Report as an exhibit thereto.

IV. Due Diligence Design

On the basis of the information obtained as a result of our RCOI, we conducted a broader due diligence investigation regarding the source and

chain of custody of the Conflict Minerals contained in our products. There is significant overlap between our RCOI and due diligence processes, and the due diligence measures that we put in place are an extension of the CMRT-based RCOI process.

These due diligence measures have been designed to conform, in all material respects, with the framework specified in the Organization for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from

Conflict-Affected and High Risk Areas, Second Edition, including the related supplements on gold, tin, tantalum and tungsten (the “OECD Guidance”), specifically as the OECD Guidance pertains to downstream purchasers in the minerals

supply chain. The OECD Guidance specifies a five-step framework for risk-based due diligence for responsible supply chains of minerals sourced from conflict-affected and high-risk areas.

2

V. Due Diligence Performed

Step 1: Establish Strong Company Management Systems.

| |

• |

|

Marvell maintains a Policy Statement on Conflict Minerals (the “Conflict Minerals Policy”), which provides that Marvell does not support the use of Conflict Minerals that are mined, transported or traded to

fund human rights violations, social unrest, political repression or conflict or the use of metal derived from such Conflict Minerals. The Conflict Minerals Policy has been posted on our website at www.marvell.com under the heading “Investor Relations - Corporate Governance and Social Responsibility.” |

| |

• |

|

Marvell also maintains a Supplier Code of Conduct that, among other things, requires our suppliers to comply with the Conflict Minerals Policy, as well as with the Marvell Code of Ethics and the EICC Code of Conduct.

The Supplier Code of Conduct is also posted on our website at www.marvell.com under the heading “Investor Relations - Corporate Governance and Social Responsibility.” |

| |

• |

|

The implementation of Marvell’s RCOI and the conducting of due diligence on the source and chain of custody of Marvell’s necessary Conflict Minerals are managed by a cross-functional Conflict Minerals Working

Group under the direction of the Corporate Social Responsibility section of our Legal Department and with oversight by our Corporate Social Responsibility Committee (the “ CSR Committee”). The Conflict Minerals Working Group, comprised of

subject matter experts from the Quality Systems group within our Operations organization and from our Legal Department, reports its activities to the CSR Committee at each of its meetings, and a representative of the CSR Committee reports at least

once a year to the Audit Committee of our Board of Directors. The CSR Committee includes representatives from our Facilities, Finance, Human Resources, Internal Audit, Legal and Operations Departments. |

| |

• |

|

We used a multi-layer approach to convey our supplier responsibility expectations to our direct suppliers. All of our direct suppliers have been provided with our Conflict Minerals Policy, Supplier Code of Conduct and

Product and Manufacturing Specifications, and these documents are provided to new suppliers as part of our Conflict Minerals due diligence process. Marvell’s Product and Manufacturing Specifications contain provisions requiring that suppliers

(i) comply with the Conflict Minerals Policy and the Supplier Code of Conduct and (ii) cooperate with Marvell in providing the information required by the CMRT, and also stipulate the consequences of breaching such provisions.

|

| |

• |

|

We maintain a data retention policy to retain material conflict-minerals related records electronically for a period of at least five (5) years from the date of creation. |

| |

• |

|

We maintain our Marvell Concern Line, managed by an independent firm, which is available to our employees and the general public to enable them to anonymously ask questions regarding compliance and ethical issues and to

report illegal and unethical activities, including general inquiries and grievances. Access to the Marvell Concern Line has been specifically extended to our direct suppliers. |

Step 2: Identify and Assess Risk in the Supply Chain.

| |

• |

|

We received completed CMRTs from 100% of our direct suppliers and used our suppliers’ completed CMRTs to identify smelters and refiners and determine mine and country of origin. |

|

|

|

| • We are a member of the EICC and the EICC and GeSI Conflict-Free Sourcing Initiative

(“CFSI”) working groups. As a member of the CFSI, a leading industry program that helps its members to manage risk by improving supply chain transparency with respect to Conflict Minerals, Marvell has access to CFSI RCOI data that aids us

in determining the mine or location of origin of the Conflict Minerals in our supply chain. |

|

|

3

| |

• |

|

We cross-checked information received from our suppliers against data made available by these industry organizations and against additional information obtained from our customers and our own research to determine

whether such facilities are validated by the Conflict-Free Sourcing Program (the “CFSP”) developed by the CFSI. When necessary, we engaged with smelters and refiners that we identified as high-risk to encourage such facilities to obtain a

“conflict-free” designation from an independent third-party audit program. |

Step 3: Design and Implement a

Strategy to Respond to Identified Risks.

| |

• |

|

We have developed procedures for sending CMRTs to our suppliers on a bi-annual basis, reviewing their responses, consolidating the information in a central database and following up with the suppliers to address any

incomplete or inconsistent responses. |

| |

• |

|

We encourage our suppliers to conduct investigations of any smelters or refiners that we identified as high-risk, work with our suppliers to mitigate such risk and, where unsuccessful, transition their processing to

CFSP validated smelters or refiners. |

| |

• |

|

If, on the basis of red flags that are identified as a result of either (i) the supplier data acquisition or engagement processes or (ii) the receipt of information from other sources, Marvell determines that

there is a reasonable risk that a supplier is sourcing Conflict Minerals that are directly or indirectly financing or benefiting armed groups, Marvell will enforce the Conflict Minerals Policy and the Supplier Code of Conduct and the other policies

incorporated therein by means of a series of escalations. |

| |

• |

|

Such escalations shall be determined at the discretion of the Conflict Minerals Working Group and, as appropriate, of the CSR Committee and the Audit Committee of the Board of Directors, and may range from prompt

engagement with the supplier to resolve the sourcing issue, to requiring such supplier to implement a risk management plan (which plan may involve, as appropriate, remedial action up to and including disengagement from upstream suppliers), to

disengagement by Marvell from the applicable supplier. |

Step 4: Carry Out Independent Third-Party Audit of Supply

Chain Due Diligence.

Given that we do not source Conflict Minerals directly from smelters and refiners, we rely on third parties,

including the CFSP, to coordinate and conduct third-party audits of these facilities. We rely on the published results of these third-party audits to validate the responsible sourcing practices of the smelters and refiners in our supply chain.

Step 5: Report on Supply Chain Due Diligence.

As required by the Rule, we have filed a Form SD and a Conflict Minerals Report as an exhibit thereto for the 2014 calendar year reporting

period. The Form SD and Conflict Minerals Report are also available on our website at www.marvell.com under the heading “Investor Relations - Corporate Governance and Social Responsibility.”

VI. Conflict Minerals Processing Facilities

Based on the information provided by our direct suppliers, and otherwise obtained through the due diligence process described above, we have

provided information regarding the processing facilities from which we source the Conflict Minerals contained in our products on Appendix A to this Report. Because some of our direct suppliers provided supply chain information on a company

level rather than on a product level, this list may include facilities that did not actually process Conflict Minerals contained in our products.

4

VII. Country of Origin of Conflict Minerals

Based on the information provided by our direct suppliers, and otherwise obtained through the due diligence process described above, some of

the Conflict Minerals necessary to the functionality or production of our products may have originated from mines located in the Covered Countries. As shown on Appendix A, we determined during our due diligence that many of the smelters and

refiners providing minerals to our direct suppliers, which may have originated from mines located in the Covered Countries, are CFSP-validated or actively engaged in the CFSP compliance process. For the CFSP “known smelters” whose

status is unknown, we have not received information indicating or suggesting that our sourcing of necessary Conflict Minerals benefitted armed groups in any of the Covered Countries.

VIII. Efforts to Determine Mine or Location of Origin

As a downstream company, the primary focus of our due diligence on the source and chain of custody of the Conflict Minerals in our supply chain

was on the collection and assessment of the CMRT data provided by our direct suppliers. As described above, we supplemented that data using data obtained from the CFSI, our customers and our own research. We were unable to ascertain the country of

origin of all necessary Conflict Minerals contained in our products because certain smelters and refiners had not yet received a “conflict-free” designation from an independent third-party audit program and did not respond to our requests

for country of origin data.

IX. Results of Conflict Minerals Due Diligence

Based on the results of the due diligence process with respect to the source and chain of custody of the Conflict Minerals contained in our

products conducted for the 2014 reporting year, we do not have sufficient information to determine whether or not the Conflict Minerals contained in our products directly or indirectly finance or benefit armed groups in the Covered Countries.

X. Independent Private Sector Audit

Given that Marvell has not voluntarily elected to describe any of its products as “DRC conflict free,” an independent private sector

audit of this Report has not been conducted.

XI. Steps to Mitigate Risk

The Company intends to take the following steps, among others, to further mitigate the risk that the Conflict Minerals necessary to the

functionality or production of our products benefit armed groups in the Covered Countries:

| |

• |

|

We intend to continue to monitor our direct suppliers’ Conflict Minerals sourcing practices to ensure that our direct suppliers remain in compliance with our Conflict Minerals Policy and Supplier Code of Conduct.

|

| |

• |

|

We intend to continue to engage with our direct suppliers, and, when necessary, the smelters and refiners from which our suppliers source Conflict Minerals, to obtain current, accurate and complete information regarding

our supply chain, including CFSI “known smelters” listed on the CFSI’s Standard Smelter List and the location of the mines from which the Conflict Minerals originate. |

| |

• |

|

We intend to continue to encourage our direct suppliers to adhere to our Conflict Minerals Policy and our Supplier Code of Conduct and in turn encourage their smelters and refiners to obtain a “conflict-free”

designation from an independent third-party audit program. |

| |

• |

|

We intend to continue to, when necessary, directly encourage the smelters and refiners from which our suppliers source Conflict Minerals to obtain a “conflict-free” designation from an independent third-party

audit program. |

5

| |

• |

|

We intend to advise any of our direct suppliers found to be sourcing from smelters or refiners that we identify as high-risk to establish an alternative source for Conflict Minerals. |

| |

• |

|

We intend to continue to engage in EICC, CSFI and other industry initiatives promoting “conflict-free” supply chains. |

* * * *

FORWARD LOOKING STATEMENTS

Statements relating

to due diligence improvements are forward-looking in nature and are based on Marvell’s management’s current expectations or beliefs. These forward-looking statements are not a guarantee of performance and are subject to a number of

uncertainties and other factors that may be outside of Marvell’s control and that could cause actual events to differ materially from those expressed or implied by the statements made herein.

DOCUMENTS INCORPORATED BY REFERENCE

Unless

otherwise stated herein, any documents, third-party materials or references to websites (including Marvell’s) are not incorporated by reference in, or considered to be a part of, this CMR, unless expressly incorporated by reference herein.

6

Appendix A

Conflict Minerals Processing Facilities as of May 13, 2015

For the 2014 reporting year, our suppliers identified 235 smelters and refiners as potential sources of conflict minerals. Of such smelters and refiners, 152

have been validated as “conflict-free” by the CFSP or other independent third-party audit program and an additional 34 are active with the CFSP, which represents a total of 79 percent of the smelters in our supply chain. The following

tables contain the names of CFSI “known smelters” listed on the CFSI’s Standard Smelter List that are used by our direct suppliers and that have been identified by the CFSP or other independent third-party audit program as:

| |

1. |

“Validated” with the CFSP assessment and audit protocol or other independent third-party audit program; |

| |

2. |

“Active” toward CFSP validation as a result of agreeing to complete a CFSP validation audit conducted by an independent third-party auditor; or |

| |

3. |

“Not Active” as a result of appearing on the CFSI’s Standard Smelter List but not having agreed to complete a CFSP validation audit conducted by an independent third-party auditor. |

This list does not include processing facilities that have not been identified as “known smelters” by the CFSI.

|

|

|

|

|

|

|

|

|

|

|

| |

|

Gold |

|

Tantalum |

|

Tin |

|

Tungsten |

|

Total |

| Validated |

|

65 |

|

38 |

|

35 |

|

14 |

|

152 (65%) |

| Active |

|

6 |

|

0 |

|

12 |

|

16 |

|

34 (14%) |

| Not Active |

|

31 |

|

0 |

|

17 |

|

1 |

|

49 (21%) |

| Total |

|

102 |

|

38 |

|

64 |

|

31 |

|

235 |

|

|

|

|

|

| MINERAL |

|

SMELTER NAME |

|

STATUS |

| Gold |

|

Aida Chemical Industries Co. Ltd. |

|

Validated |

| Gold |

|

Allgemeine Gold-und Silberscheideanstalt A.G. |

|

Validated |

| Gold |

|

Almalyk Mining and Metallurgical Complex (AMMC) |

|

Not Active |

| Gold |

|

AngloGold Ashanti Córrego do Sítio Minerção |

|

Validated |

| Gold |

|

Argor-Heraeus SA |

|

Validated |

| Gold |

|

Asahi Pretec Corporation |

|

Validated |

| Gold |

|

Asaka Riken Co Ltd |

|

Active |

| Gold |

|

Atasay Kuyumculuk Sanayi Ve Ticaret A.S. |

|

Validated |

| Gold |

|

Aurubis AG |

|

Validated |

| Gold |

|

Bangko Sentral ng Pilipinas (Central Bank of the Philippines) |

|

Not Active |

| Gold |

|

Bauer Walser AG |

|

Not Active |

| Gold |

|

Boliden AB |

|

Validated |

| Gold |

|

C. Hafner GmbH + Co. KG |

|

Validated |

| Gold |

|

Caridad |

|

Not Active |

| Gold |

|

CCR Refinery – Glencore Canada Corporation |

|

Validated |

| Gold |

|

Cendres + Métaux SA |

|

Active |

|

|

|

|

|

| Gold |

|

Chimet S.p.A. |

|

Validated |

| Gold |

|

Chugai Mining |

|

Not Active |

| Gold |

|

Daejin Indus Co. Ltd |

|

Not Active |

| Gold |

|

Daye Non-Ferrous Metals Mining Ltd. |

|

Not Active |

| Gold |

|

Do Sung Corporation |

|

Not Active |

| Gold |

|

Doduco |

|

Active |

| Gold |

|

Dowa |

|

Validated |

| Gold |

|

Eco-System Recycling Co., Ltd. |

|

Validated |

| Gold |

|

FSE Novosibirsk Refinery |

|

Not Active |

| Gold |

|

Gansu Seemine Material Hi-Tech Co Ltd |

|

Not Active |

| Gold |

|

Guangdong Jinding Gold Limited |

|

Not Active |

| Gold |

|

Hangzhou Fuchunjiang Smelting Co., Ltd. |

|

Not Active |

| Gold |

|

Heimerle + Meule GmbH |

|

Validated |

| Gold |

|

Heraeus Ltd. Hong Kong |

|

Validated |

| Gold |

|

Heraeus Precious Metals GmbH & Co. KG |

|

Validated |

| Gold |

|

Hunan Chenzhou Mining Group Co., Ltd. |

|

Not Active |

| Gold |

|

Hwasung CJ Co. Ltd |

|

Not Active |

| Gold |

|

Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited |

|

Not Active |

| Gold |

|

Ishifuku Metal Industry Co., Ltd. |

|

Validated |

| Gold |

|

Istanbul Gold Refinery |

|

Validated |

| Gold |

|

Japan Mint |

|

Validated |

| Gold |

|

Jiangxi Copper Company Limited |

|

Not Active |

| Gold |

|

Johnson Matthey Inc |

|

Validated |

| Gold |

|

Johnson Matthey Ltd |

|

Validated |

| Gold |

|

JSC Ekaterinburg Non-Ferrous Metal Processing Plant |

|

Validated |

| Gold |

|

JSC Uralelectromed |

|

Validated |

| Gold |

|

JX Nippon Mining & Metals Co., Ltd. |

|

Validated |

| Gold |

|

Kazzinc Ltd |

|

Validated |

| Gold |

|

Kennecott Utah Copper LLC |

|

Validated |

| Gold |

|

Kojima Chemicals Co., Ltd |

|

Validated |

| Gold |

|

Korea Metal Co. Ltd |

|

Not Active |

| Gold |

|

Kyrgyzaltyn JSC |

|

Not Active |

| Gold |

|

L’ azurde Company For Jewelry |

|

Validated |

| Gold |

|

Lingbao Jinyuan Tonghui Refinery Co. Ltd. |

|

Not Active |

| Gold |

|

LS-NIKKO Copper Inc. |

|

Validated |

| Gold |

|

Luoyang Zijin Yinhui Metal Smelt Co Ltd |

|

Not Active |

| Gold |

|

Materion |

|

Validated |

| Gold |

|

Matsuda Sangyo Co., Ltd. |

|

Validated |

| Gold |

|

Metalor Technologies (Hong Kong) Ltd |

|

Validated |

2

|

|

|

|

|

| Gold |

|

Metalor Technologies (Singapore) Pte. Ltd. |

|

Validated |

| Gold |

|

Metalor Technologies SA |

|

Validated |

| Gold |

|

Metalor USA Refining Corporation |

|

Validated |

| Gold |

|

METALÚRGICA MET-MEX PEÑOLES, S.A. DE C.V |

|

Validated |

| Gold |

|

Mitsubishi Materials Corporation |

|

Validated |

| Gold |

|

Mitsui Mining and Smelting Co., Ltd. |

|

Validated |

| Gold |

|

Moscow Special Alloys Processing Plant |

|

Not Active |

| Gold |

|

Nadir Metal Rafineri San. Ve Tic. A.Ş. |

|

Validated |

| Gold |

|

Navoi Mining and Metallurgical Combinat |

|

Not Active |

| Gold |

|

Nihon Material Co. LTD |

|

Validated |

| Gold |

|

Ohio Precious Metals, LLC |

|

Validated |

| Gold |

|

Ohura Precious Metal Industry Co., Ltd |

|

Validated |

| Gold |

|

OJSC “The Gulidov Krasnoyarsk Non-Ferrous Metals Plant” (OJSC Krastvetmet) |

|

Validated |

| Gold |

|

OJSC Kolyma Refinery |

|

Not Active |

| Gold |

|

PAMP SA |

|

Validated |

| Gold |

|

Penglai Penggang Gold Industry Co Ltd |

|

Not Active |

| Gold |

|

Prioksky Plant of Non-Ferrous Metals |

|

Not Active |

| Gold |

|

PT Aneka Tambang (Persero) Tbk |

|

Validated |

| Gold |

|

PX Précinox SA |

|

Validated |

| Gold |

|

Rand Refinery (Pty) Ltd |

|

Validated |

| Gold |

|

Royal Canadian Mint |

|

Validated |

| Gold |

|

Sabin Metal Corp. |

|

Not Active |

| Gold |

|

SAMWON METALS Corp. |

|

Not Active |

| Gold |

|

Schone Edelmetaal |

|

Validated |

| Gold |

|

SEMPSA Joyería Platería SA |

|

Validated |

| Gold |

|

Shandong Zhaojin Gold & Silver Refinery Co. Ltd |

|

Validated |

| Gold |

|

So Accurate Group, Inc. |

|

Not Active |

| Gold |

|

SOE Shyolkovsky Factory of Secondary Precious Metals |

|

Active |

| Gold |

|

Solar Applied Materials Technology Corp. |

|

Validated |

| Gold |

|

Sumitomo Metal Mining Co., Ltd. |

|

Validated |

| Gold |

|

Tanaka Kikinzoku Kogyo K.K. |

|

Validated |

| Gold |

|

The Great Wall Gold and Silver Refinery of China |

|

Not Active |

| Gold |

|

The Refinery of Shandong Gold Mining Co. Ltd |

|

Validated |

| Gold |

|

Tokuriki Honten Co., Ltd |

|

Validated |

| Gold |

|

Tongling nonferrous Metals Group Co.,Ltd |

|

Not Active |

| Gold |

|

Torecom |

|

Active |

| Gold |

|

Umicore Brasil Ltda |

|

Validated |

| Gold |

|

Umicore Precious Metals Thailand |

|

Validated |

| Gold |

|

Umicore SA Business Unit Precious Metals Refining |

|

Validated |

3

|

|

|

|

|

| Gold |

|

United Precious Metal Refining, Inc. |

|

Validated |

| Gold |

|

Valcambi SA |

|

Validated |

| Gold |

|

Western Australian Mint trading as The Perth Mint |

|

Validated |

| Gold |

|

YAMAMOTO PRECIOUS METAL CO., LTD. |

|

Validated |

| Gold |

|

Yokohama Metal Co Ltd |

|

Active |

| Gold |

|

Yunnan Copper Industry Co Ltd |

|

Not Active |

| Gold |

|

Zhongyuan Gold Smelter of Zhongjin Gold Corporation |

|

Validated |

| Gold |

|

Zijin Mining Group Co. Ltd |

|

Validated |

| Tantalum |

|

Changsha South Tantalum Niobium Co., Ltd. |

|

Validated |

| Tantalum |

|

Conghua Tantalum and Niobium Smeltry |

|

Validated |

| Tantalum |

|

Duoluoshan |

|

Validated |

| Tantalum |

|

Exotech Inc. |

|

Validated |

| Tantalum |

|

F&X Electro-Materials Ltd. |

|

Validated |

| Tantalum |

|

Global Advanced Metals Aizu |

|

Validated |

| Tantalum |

|

Global Advanced Metals Boyertown |

|

Validated |

| Tantalum |

|

Guangdong Zhiyuan New Material Co., Ltd. |

|

Validated |

| Tantalum |

|

H.C. Starck Co., Ltd. |

|

Validated |

| Tantalum |

|

H.C. Starck GmbH Goslar |

|

Validated |

| Tantalum |

|

H.C. Starck GmbH Laufenburg |

|

Validated |

| Tantalum |

|

H.C. Starck Hermsdorf GmbH |

|

Validated |

| Tantalum |

|

H.C. Starck Inc. |

|

Validated |

| Tantalum |

|

H.C. Starck Ltd. |

|

Validated |

| Tantalum |

|

H.C. Starck Smelting GmbH & Co.KG |

|

Validated |

| Tantalum |

|

Hengyang King Xing Lifeng New Materials Co., Ltd. |

|

Validated |

| Tantalum |

|

Hi-Temp |

|

Validated |

| Tantalum |

|

JiuJiang JinXin Nonferrous Metals Co., Ltd. |

|

Validated |

| Tantalum |

|

Jiujiang Tanbre Co., Ltd. |

|

Validated |

| Tantalum |

|

Kemet Blue Powder |

|

Validated |

| Tantalum |

|

Kemet Blue Metals |

|

Validated |

| Tantalum |

|

King-Tan Tantalum Industry Ltd |

|

Validated |

| Tantalum |

|

LSM Brasil S.A. |

|

Validated |

| Tantalum |

|

Metallurgical Products India (Pvt.) Ltd. |

|

Validated |

| Tantalum |

|

Mineração Taboca S.A. |

|

Validated |

| Tantalum |

|

Mitsui Mining & Smelting |

|

Validated |

| Tantalum |

|

Molycorp Silmet A.S. |

|

Validated |

| Tantalum |

|

Ningxia Orient Tantalum Industry Co., Ltd. |

|

Validated |

| Tantalum |

|

Plansee SE Liezen |

|

Validated |

| Tantalum |

|

Plansee SE Reutte |

|

Validated |

| Tantalum |

|

QuantumClean |

|

Validated |

4

|

|

|

|

|

| Tantalum |

|

RFH Tantalum Smeltry Co., Ltd |

|

Validated |

| Tantalum |

|

Solikamsk Magnesium Works OAO |

|

Validated |

| Tantalum |

|

Taki Chemicals |

|

Validated |

| Tantalum |

|

Telex |

|

Validated |

| Tantalum |

|

Ulba |

|

Validated |

| Tantalum |

|

Yichun Jin Yang Rare Metal Co., Ltd |

|

Validated |

| Tantalum |

|

Zhuzhou Cement Carbide |

|

Validated |

| Tin |

|

Alpha |

|

Validated |

| Tin |

|

China Tin Group Co., Ltd. |

|

Active |

| Tin |

|

CNMC (Guangxi) PGMA Co. Ltd. |

|

Not Active |

| Tin |

|

Cooperativa Metalurgica de Rondônia Ltda |

|

Validated |

| Tin |

|

CV Gita Pesona |

|

Not Active |

| Tin |

|

CV JusTindo |

|

Active |

| Tin |

|

CV Serumpun Sebalai |

|

Not Active |

| Tin |

|

CV United Smelting |

|

Validated |

| Tin |

|

Dowa |

|

Validated |

| Tin |

|

EM Vinto |

|

Validated |

| Tin |

|

Estanho de Rondônia S.A. |

|

Not Active |

| Tin |

|

Fenix Metals |

|

Active |

| Tin |

|

Gejiu Kai Meng Industry and Trade LLC |

|

Not Active |

| Tin |

|

Gejiu Non-Ferrous Metal Processing Co. Ltd. |

|

Validated |

| Tin |

|

Gejiu Zi-Li |

|

Not Active |

| Tin |

|

Huichang Jinshunda Tin Co. Ltd |

|

Not Active |

| Tin |

|

Jiangxi Ketai Advanced Material Co., Ltd. |

|

Validated |

| Tin |

|

Linwu Xianggui Smelter Co |

|

Not Active |

| Tin |

|

Magnu’s Minerais Metais e Ligas LTDA |

|

Validated |

| Tin |

|

Malaysia Smelting Corporation (MSC) |

|

Validated |

| Tin |

|

Melt Metais e Ligas S/A |

|

Validated |

| Tin |

|

Mineração Taboca S.A. |

|

Validated |

| Tin |

|

Minsur |

|

Validated |

| Tin |

|

Mitsubishi Materials Corporation |

|

Validated |

| Tin |

|

Nankang Nanshan Tin Manufactory Co., Ltd |

|

Not Active |

| Tin |

|

Novosibirsk Integrated Tin Works |

|

Not Active |

| Tin |

|

O.M. Manufacturing (Thailand) Co., Ltd. |

|

Active |

| Tin |

|

OMSA |

|

Validated |

| Tin |

|

PT Alam Lestari Kencana |

|

Not Active |

| Tin |

|

PT Aries Kencana Sejahtera |

|

Active |

| Tin |

|

PT Artha Cipta Langgeng |

|

Validated |

| Tin |

|

PT ATD Makmur Mandiri Jaya |

|

Validated |

5

|

|

|

|

|

| Tin |

|

PT Babel Inti Perkasa |

|

Validated |

| Tin |

|

PT Bangka Kudai Tin |

|

Not Active |

| Tin |

|

PT Bangka Putra Karya |

|

Validated |

| Tin |

|

PT Bangka Timah Utama Sejahtera |

|

Not Active |

| Tin |

|

PT Bangka Tin Industry |

|

Validated |

| Tin |

|

PT Belitung Industri Sejahtera |

|

Validated |

| Tin |

|

PT BilliTin Makmur Lestari |

|

Active |

| Tin |

|

PT Bukit Timah |

|

Validated |

| Tin |

|

PT DS Jaya Abadi |

|

Validated |

| Tin |

|

PT Eunindo Usaha Mandiri |

|

Validated |

| Tin |

|

PT Fang Di MulTindo |

|

Not Active |

| Tin |

|

PT Inti Stania Prima |

|

Active |

| Tin |

|

PT Karimun Mining |

|

Active |

| Tin |

|

PT Mitra Stania Prima |

|

Validated |

| Tin |

|

PT Panca Mega Persada |

|

Validated |

| Tin |

|

PT Pelat Timah Nusantara Tbk |

|

Not Active |

| Tin |

|

PT Prima Timah Utama |

|

Validated |

| Tin |

|

PT REFINED BANGKA TIN |

|

Validated |

| Tin |

|

PT Sariwiguna Binasentosa |

|

Validated |

| Tin |

|

PT Seirama Tin investment |

|

Not Active |

| Tin |

|

PT Stanindo Inti Perkasa |

|

Validated |

| Tin |

|

PT Sumber Jaya Indah |

|

Active |

| Tin |

|

PT Supra Sukses Trinusa |

|

Not Active |

| Tin |

|

PT Timah (Persero) Tbk Kundur |

|

Validated |

| Tin |

|

PT Timah (Persero) Tbk Mentok |

|

Validated |

| Tin |

|

PT Tinindo Inter Nusa |

|

Validated |

| Tin |

|

Rui Da Hung |

|

Active |

| Tin |

|

Soft Metais, Ltda. |

|

Active |

| Tin |

|

Thaisarco |

|

Validated |

| Tin |

|

White Solder Metalurgia e Mineração Ltda. |

|

Validated |

| Tin |

|

Yunnan Chengfeng Non-ferrous Metals Co.,Ltd. |

|

Active |

| Tin |

|

Yunnan Tin Company, Ltd. |

|

Validated |

| Tungsten |

|

A.L.M.T. Corp. |

|

Active |

| Tungsten |

|

Chenzhou Diamond Tungsten Products Co., Ltd. |

|

Validated |

| Tungsten |

|

Chongyi Zhangyuan Tungsten Co., Ltd. |

|

Active |

| Tungsten |

|

Dayu Weiliang Tungsten Co., Ltd. |

|

Active |

| Tungsten |

|

Fujian Jinxin Tungsten Co., Ltd. |

|

Validated |

| Tungsten |

|

Ganzhou Huaxing Tungsten Products Co., Ltd. |

|

Validated |

| Tungsten |

|

Ganzhou Jiangwu Ferrotungsten Co., Ltd. |

|

Validated |

6

|

|

|

|

|

| Tungsten |

|

Ganzhou Non-ferrous Metals Smelting Co., Ltd. |

|

Active |

| Tungsten |

|

Ganzhou Seadragon W & Mo Co., Ltd. |

|

Validated |

| Tungsten |

|

Global Tungsten & Powders Corp. |

|

Validated |

| Tungsten |

|

Guangdong Xianglu Tungsten Co., Ltd. |

|

Active |

| Tungsten |

|

H.C. Starck GmbH |

|

Active |

| Tungsten |

|

H.C. Starck Smelting GmbH & Co.KG |

|

Active |

| Tungsten |

|

Hunan Chenzhou Mining Group Co., Ltd. |

|

Active |

| Tungsten |

|

Hunan Chun-Chang Nonferrous Smelting & Concentrating Co., Ltd. |

|

Validated |

| Tungsten |

|

Japan New Metals Co., Ltd. |

|

Validated |

| Tungsten |

|

Jiangwu H.C. Starck Tungsten Products Co., Ltd. |

|

Active |

| Tungsten |

|

Jiangxi Gan Bei Tungsten Co., Ltd. |

|

Validated |

| Tungsten |

|

Jiangxi Minmetals Gao’an Non-ferrous Metals Co., Ltd. |

|

Not Active |

| Tungsten |

|

Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. |

|

Active |

| Tungsten |

|

Jiangxi Xinsheng Tungsten Industry Co., Ltd. |

|

Active |

| Tungsten |

|

Kennametal Fallon |

|

Active |

| Tungsten |

|

Kennametal Huntsville |

|

Active |

| Tungsten |

|

Malipo Haiyu Tungsten Co., Ltd. |

|

Validated |

| Tungsten |

|

Nui Phao H.C. Starck Tungsten Chemicals Manufacturing LLC |

|

Active |

| Tungsten |

|

Tejing (Vietnam) Tungsten Co., Ltd. |

|

Active |

| Tungsten |

|

Vietnam Youngsun Tungsten Industry Co., Ltd |

|

Validated |

| Tungsten |

|

Wolfram Bergbau und Hütten AG |

|

Validated |

| Tungsten |

|

Xiamen Tungsten (H.C.) Co., Ltd. |

|

Validated |

| Tungsten |

|

Xiamen Tungsten Co., Ltd. |

|

Validated |

| Tungsten |

|

Xinhai Rendan Shaoguan Tungsten Co., Ltd. |

|

Active |

The “Validated” smelters and refiners in the list above that report country of origin information to the CFSI

reported that the Conflict Minerals processed by these facilities originated from the following countries:

Angola, Argentina, Australia, Austria,

Belgium, Bolivia, Brazil, Burundi, Canada, Central African Republic, Chile, China, Colombia, Cote D’Ivoire, Czech Republic, Democratic Republic of the Congo, Djibouti, Egypt, Estonia, Ethiopia, France, Germany, Guyana, Hungary, India,

Indonesia, Ireland, Israel, Japan, Kazakhstan, Kenya, Laos, Luxembourg, Madagascar, Malaysia, Mongolia, Mozambique, Myanmar, Namibia, Netherlands, Nigeria, Peru, Portugal, Republic of Congo, Russia, Rwanda, Sierra Leone, Singapore, Slovakia, South

Africa, South Korea, South Sudan, Spain, Suriname, Switzerland, Taiwan, Tanzania, United Kingdom, United States of America, Uganda, Vietnam, Zambia and Zimbabwe.

7

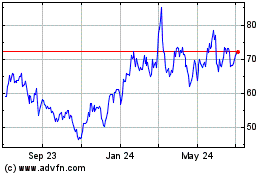

Marvell Technology (NASDAQ:MRVL)

Historical Stock Chart

From Mar 2024 to Apr 2024

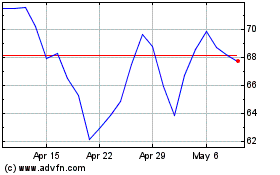

Marvell Technology (NASDAQ:MRVL)

Historical Stock Chart

From Apr 2023 to Apr 2024