UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

LAM RESEARCH

CORPORATION

(Exact name of registrant as specified in its charter)

|

|

|

|

|

| Delaware |

|

0-12933 |

|

94-2634797 |

| (State or other jurisdiction

of incorporation) |

|

(Commission File

Number) |

|

(I.R.S. Employer

Identification No.) |

4650 Cushing Parkway

Fremont, California 94538

(Address of principal executive offices, including zip code)

Douglas R. Bettinger

Executive Vice President and Chief Financial Officer

(510) 572-0200

(Name and

telephone number, including area code, of the person

to contact in connection with this report)

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form

applies:

| x |

Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

Section 1 – Conflict Minerals Disclosure

| Item 1.01. |

Conflict Minerals Disclosure and Report. |

Conflict Minerals Disclosure

Lam Research Corporation (the “Company”) conducted in good faith a reasonable country of origin inquiry regarding the conflict minerals (as defined

in Form SD) that are necessary to the functionality or production of a product that the Company manufactured or contracted to have manufactured in calendar year 2014 (the “Covered Minerals”). The inquiry was reasonably designed to

determine if the Covered Minerals originated in the Democratic Republic of the Congo or an adjoining country or are from recycled or scrap sources.

The

Company has determined that it is required to file, and has filed, a Conflict Minerals Report as Exhibit 1.01 to this Form SD. The Conflict Minerals Report is also publicly available at http://investor.lamresearch.com/sec.cfm. The content on

any web site referred to in this Form SD is not incorporated by reference into this Form SD unless expressly noted.

The Company’s Conflict Mineral Report is included as Exhibit 1.01 to this report.

Section 2 – Exhibits

|

|

|

| Exhibit

Number |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report of Lam Research Corporation. |

2

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the Company has duly caused this report to be signed on its behalf by the

undersigned hereunto duly authorized.

Date: June 1, 2015

|

|

|

|

|

| LAM RESEARCH CORPORATION |

|

|

| By: |

|

/s/ Douglas R. Bettinger |

|

|

Name: |

|

Douglas R. Bettinger |

|

|

Title: |

|

Executive Vice President and Chief Financial

Officer |

3

EXHIBIT INDEX

|

|

|

| Exhibit No. |

|

Description |

|

|

| 1.01 |

|

Conflict Minerals Report of Lam Research Corporation. |

4

Exhibit 1.01

LAM RESEARCH CORPORATION

CONFLICT MINERALS REPORT

For the reporting period from January 1, 2014 through December 31, 2014

This Conflict Minerals Report (this “Report”) of Lam Research Corporation (including its consolidated subsidiaries,

the “Company”) has been prepared pursuant to Rule 13p-1 and Form SD promulgated under the Securities Exchange Act of 1934, for the reporting period January 1, 2014 through December 31, 2014 (the “Reporting

Period”).

Rule 13p-1, through Form SD, requires the disclosure of certain information if a company manufactures or contracts to

manufacture products for which certain “Subject Minerals” (as defined below) are necessary to the functionality or production of such products. “Subject Minerals” are defined herein as: (i)(a) columbite-tantalite (or coltan),

(b) cassiterite, (c) gold and (d) wolframite, or their derivatives, which are currently limited to tantalum, tin and tungsten; or (ii) any other mineral or its derivatives determined by the U.S. Secretary of State to be financing

conflict in the Democratic Republic of the Congo or an adjoining country (collectively, the “Covered Countries”).

The

Company’s operations may at times manufacture, or contract to manufacture, products for which Subject Minerals are necessary to the functionality or production of those products (collectively, its “products” and, individually, a

“product”). As required by Form SD, the Company has conducted a good faith reasonable country of origin inquiry regarding the Subject Minerals included in its products manufactured or contracted to be manufactured during the Reporting

Period, which are referred to in this Report as the “Covered Minerals,” to determine whether any of such Covered Minerals originated in the Covered Countries and/or whether any of such Covered Minerals may be from recycled or scrap

sources. Where applicable, the Company has conducted additional due diligence regarding the sources of the Covered Minerals. The results of the Company’s reasonable country of origin inquiry regarding the Covered Minerals, as well as its

additional due diligence regarding the sources of the Covered Minerals, are contained in this Report.

| I. |

Reasonable Country of Origin Inquiry (“RCOI”) |

| |

A. |

During the Reporting Period, the Company took the following measures, based on the Organization for Economic Cooperation and Development’s (“OECD”) due diligence framework, including resources provided by

the Electronic Industry Citizenship Coalition and Global e-Sustainability Initiative (together, the “EICC-GeSI”), such as the EICC-GeSI Reporting Template, to determine the source and chain of custody for the Covered Minerals.

|

| |

1. |

The Company sent a letter in June 2014 to its direct-spend suppliers which the Company believed could provide materials containing Covered Minerals (collectively, the “Covered Suppliers”) requesting that such

suppliers: (a) determine whether they supplied the Company with Covered Minerals; (b) using resources provided by the EICC-GeSI, identify smelters in their supply chain that supply Covered Minerals; and (c) download, complete and

return the EICC-GeSI Reporting Template to the Company. |

1

| |

2. |

The Company subsequently: (a) filed and logged received responses; (b) followed up with Covered Suppliers that had provided incomplete information, conflicting information or a response the Company believed

required clarification; and (c) continued to make efforts to engage Covered Suppliers that did not respond to the Company’s requests for information through various channels of communication. |

| |

B. |

After taking the measures described in A. above, the Company was unable to determine whether its products manufactured or contracted to be manufactured during the Reporting Period contain Covered Minerals from the

Covered Countries. As a result, the Company exercised due diligence on the source and chain of custody of Covered Minerals in its supply chain as described in Part II below. |

| II. |

Due Diligence and Risk Mitigation |

The Company’s due diligence process,

which significantly overlaps the Company’s RCOI process described above, is based on the OECD’s due diligence guidelines. In addition to the RCOI, the Company has done the following since the start of 2014 to determine the mine or location

of origin for the Covered Minerals included in its products:

| |

1. |

Company Management Systems |

| |

a. |

Maintain Appropriate Organizational Structure to Support Due Diligence |

The Company has

established an organizational structure to support its due diligence process that includes processes for handling requests for information, escalations to management regarding any issues or problems, surveying of suppliers and documentation of any

responses and red flags associated therewith.

The Company’s due diligence process is carried out by individuals in the

Company’s supply chain organization, who are supported by an inter-disciplinary support team comprised of members of the legal department, finance, engineering, customer account teams and environmental health and safety departments to help

address any questions associated with the reasonable country of origin inquiry and/or due diligence process.

The Company continues to

make available online training regarding conflict minerals regulation and the impact thereof on the Company for the following groups of individuals: (i) supply chain business managers; (ii) representatives of the customer account teams;

(iii) directors of the environmental health and safety group; (iv) senior management of the supplier engineering team; and (v) senior management of the supply chain group. The Company also provides reports and briefings on the

requirements and implications to Company management.

2

| |

b. |

Communicate Conflict Mineral Policy |

The Company has adopted and communicated to

suppliers and to the public a Conflict Minerals Policy Statement. A copy of the Policy is publicly available at http://www.lamresearch.com/company/corporate-social-responsibility/supply-chain. The content on any web site referred to in this

Report is not incorporated by reference into this Report unless expressly noted.

| |

c. |

Company Engagement with Suppliers |

The Company continues to include a standard provision

in the terms and conditions of its purchase orders requiring its suppliers to promptly provide accurate, complete and timely information and documentation to assist the Company as it may request to comply with Rule 13p-1 and Form SD, including

disclosing whether any of the suppliers’ deliverables contain Covered Minerals and, if so, to provide such information as the Company may request to allow the Company to determine whether such Covered Minerals are DRC conflict free (as such

term is defined in Form SD). The Company is also in the process of incorporating similar requirements into relevant commonly used supplier contract templates to further strengthen supplier engagement in the due diligence process.

| |

d. |

Internal Process Improvements Associated with Covered Minerals |

The Company continues to

evaluate various process improvements that may be available to it at different points in the supply chain life cycle to enhance the transparency of Covered Mineral usage and disclosure.

| |

2. |

Identify and Assess Risks in the Supply Chain |

The Company’s methods for

identifying and assessing risks in the supply chain are set forth above in the description of the Company’s Reasonable Country of Origin Inquiry.

| |

3. |

Design and Implement Strategy to Respond to Risks |

| |

a. |

Devise Risk Management Plan |

The Company has prepared a risk management plan to respond

to any situations which might arise involving Covered Minerals identified as being sourced from the Covered Countries, which includes carrying out the due diligence described in this Report, understanding the products impacted by any supplied

materials identified as containing Covered Minerals, understanding the extent of the Company’s reliance on such materials, and working with the Company’s suppliers to ensure that any Covered Minerals are sourced responsibly wherever

possible.

3

| |

b. |

Reporting of Conflict Minerals Surveying Results to Management |

The Company has apprised

members of senior management of the status and results of the inquiry and due diligence process to allow for any appropriate feedback and guidance.

| |

c. |

Continued Supplier Engagement |

When necessary or requested the Company continues to work

with its suppliers to educate them about Subject Minerals and to encourage responsible sourcing and usage of independently certified conflict-free smelters and refiners.

| |

4. |

Independent Third-Party Audit of Smelter’s / Refiner’s Due Diligence Practices |

Where possible, the Company has relied on third party assurances and certifications. For example, the Company accepts as reliable any smelter

that is a member of the EICC-GeSI Conflict Free Smelter program. To the extent that other audited supplier certifications are provided to the Company, the Company may consider reliance on a case-by-case basis.

| |

5. |

Report Annually on Supply Chain Due Diligence |

This Report and the Company’s prior

annual Conflict Minerals Report for calendar year 2013 are publicly available at http://investor.lamresearch.com/sec.cfm.

The following products are within the scope of Rule 13p-1

and Form SD.

1. Etch and Photoresist Strip Products

A series of wafer fabrication products that selectively remove materials from the wafer to create features and patterns of a device and to

remove the photoresist mask:

| |

a. |

2300® Kiyo® product family |

| |

b. |

2300® Versys® Metal product family |

| |

c. |

2300® Flex™ product family |

| |

d. |

2300 Syndion® product family |

| |

f. |

TCP® 9400DSiE product family |

2. Deposition

Products

A series of high-productivity thin film deposition systems that form a device’s sub-microscopic layers of conducting

(metal) or insulating (dielectric) materials:

| |

c. |

VECTOR® product family |

4

3. Clean Products

A series of single-wafer wet and plasma-based wafer cleaning products that remove particles and residues from the wafer surface before and

after adjacent processes:

4. Legacy Products

Multiple series of

refurbished and newly built previous-generation products from Lam, as the original equipment manufacturer (“OEM”), for applications that do not require the most advanced wafer processing capability.

| IV. |

Smelter / Refiner and Country of Origin |

Based solely on information that was

provided by the Covered Suppliers (as described above), some of which was on an entity level without specification as to application with respect to the specific Covered Minerals the Company purchased, and without independent verification, the

Company believes that the facilities that were used to process the Covered Minerals may have included some or all of the EICC-GeSI and/or Conflict Free Smelter Initiative recognized smelters and/or refiners listed below:

Smelter / Refiner Facility Names

|

|

|

|

|

| Allgemeine Gold- und

Silberscheideanstalt A.G.

Accurate Refining Group

Advanced Chemical Company

Aida Chemical Industries Co.

Aktyubinsk Copper Company

Allgemeine Gold und Silberscheideanstalt A.G.

Allied Material (A.L.M.T) Corp

Allied Material Corporation

Almalyk Mining and Metallurgical Complex (AMMC)

Amalgamated Metal Corp

AngloGold Ashanti Mineração Ltda

Argor-Heraeus SA

Asahi Pretec Corp

Asahi Riken Co.

Atasay Kuyumculuk Sanayi Ve Ticaret A.S.

ATI Metalworking Products |

|

Aurubis AG

Bangko Sentral ng Pilipinas (Central Bank of the Philippines)

Bauer Walser AG

Boliden AB

Caridad

CCR Refinery – Glencore Canada Corporation

Cendres & Métaux SA

C. Hafner GMBH + Co

Chaozhou Xianglu Tungsten

Industry Co Ltd

Chimet SpA

China Minmetals Corp.

China National Gold Group Corporation

China Rare Metal Materials Company

China Tin Group Co.

Chongyi Zhangyuan Tungsten Co Ltd

Chugai Mining Co., LTD

Codelco

Colt Refining |

|

Cookson

Conghua Tantalum and

Niobium Smeltry

CooperMetal

CV DS Jaya Abadi

CV Duta Putra Bangka

CV JusTindo

CV Makmur Jaya

CV Nurjanah

CV Prima Timah Utama

CV United Smelting

CV. Serumpun Sebalai

CV Venus Inti Perkasa

D Block Metals

Daejin Indus Co.

DaeryongENC

Daye Nonferrous

Dayu Jincheng Tungsten Industry Co.

Do Sung Corp.

Doduco

Douluoshan Sapphire Rare Metal Co.

Dowa

Eco-System Recycling Co., LTD. |

5

|

|

|

|

|

| EM Vinto

Engelhard Corp.

Exotech

F&X

Fenix Metals

FIR Metals & Resource, Ltd.

FSE Novosibirsk Refinery

Fujian Jinxin Tungsten Co., LTD

Gannon & Scott

Ganzhou Grand Sea W & Mo Group Co Ltd

Ganzhou Huaxing Tungsten Co. Ltd.

Ganzhou Nonferrous Metals Smelting Co Ltd.

Ganzhou Seadragon W & Mo Co., Ltd.

Gejiu Non-Ferrous Metal Processing Co. Ltd.

Geijiu Kai Meng Industry and Trade

Gejiu Zi-Li Metallurgy Co., Ltd.

Global Advanced Metals

Global Tungsten & Powders Corp

Gold Bell Group

Guangdong Jinding Gold Ltd.

Guangxi Pinggui PGMA Co. Ltd.

Hangzhou Fuchunjiang Smelting Co., Ltd.

H.C. Starck GmbH

HC Starck GmbH

Heimerle + Meule GmbH

Heraeus Ltd Hong Kong

Heraeus Precious Metals GmbH & Co. KG

Henan Zhongyuan Gold Smelter Co.

Hengyang King Xing Lifeng New Materials Co.

Hi-Temp

Huichang Jinshunda Tin Co.

Hunan Chun-chang Non-ferrous Smelting & Concentrating Co., Ltd.

Hwasung CJ Co. Ltd.

Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited

Ishifuku Metal Industry Co., Ltd.

Istanbul Gold Refinery |

|

Japan Mint Japan New Metal

Jiangxi Copper Company Limited

Jiangxi Dinghai Tantalum & Niobium Co., Ltd.

Jiangxi Nanshan Jiangxi Rare Earth Metals Tungsten

Group Corp Jiangxi Tungsten Industry Group Co

Ltd Jiangxi Rare Earth & Rare Metals

Tungsten Group Jiangxi Richsea New Materials

Co., Ltd. Jiangxi Xiushui Xianggan Nonferrous

Metals, Co., Ltd. Jiangxi Yaosheng Tungsten

Co., Ltd. Jiujiang Jinxin Nonferous Metals

Co., Ltd Jiujiang Tambre Co., Ltd.

Jiujiang Zhongao Tantalum & Niobium Co.,

Ltd. Johnson Matthey JSC Ekaterinburg Non-Ferrous Metal

Processing Plant JSC Uralectromed

JX Nippon Mining & Metals Co., Ltd Kazzinc Ltd

Kemet Blue Powder Kennametal Inc.

KGHM Polska Miedz Spotka Akcyjna King-Tan Tantalum Industry

Ltd. Korea Metal Kojima Chemicals Co.,Ltd

Kyrgyzaltyn JSC L’ azurde Company For Jewelry

Linwu Xianggui Smelter Co. LS-Nikko Copper Inc

Luoyang Zijin Yinhui Gold Smelting

Co. Ltd. Malaysia Smelting Corp

Malipo Haiyu Tungsten Co. Ltd. Materion Advanced Metals

Matsuda Sangyo Co. Ltd Metallo Chimique

Metallurgical Products India |

|

Metalor Technologies (Hong

Kong) Ltd Metalor Technologies SA

Metalor USA Refining Corporation Met-Mex Peñoles, S.A.

Mineração Taboca S.A. Minmetals Ganzhou Tin

Mitsubishi Materials Corp. Mitsui Mining & Smelting

Molycorp Silmet Moscow Special Alloys Processing Plant

Nadir Metal Rafineri San. Ve Tic. A.Ş. Navoi Mining and

Metallurgical Combinat Nihon Material

Co., Ltd. Niihama Nickel Refinery Ningxia Orient Tantalum

Industry Co., Ltd. Nui Phao H.C.

Starck Tungsten Chemicals Manufacturing Ohio Precious Metals

Ohura Precious Metal Industry Co., Ltd. OJSC Kolyma Refinery

OMSA PAMP SA

Pan Pacific Copper Co. Ltd. Penglai Pengang Gold Co. Ltd

Plansee Prioksky Plant of Non-Ferrous Metals

PT Alam Lestari Kencana PT Aneka Tambang (Persero) Tbk

PT Artha Cipta Langgeng PT ATD Makmur Mandiri Jaya

PT Babel Inti Perkasa PT Babel Surya Alam Lestari

PT Bangka Kudai Tin PT Bangka Putra Karya

PT Bangka Timah Utama Sejahtera PT Belitung Industri

Sejahtera PT BilliTin Makmur Lestari PT Eunindo Usaha

Mandiri PT Fang Di MulTindo PT Hanjaya Perkasa Metals

PT HP Metals Indonesia PT Inti Stania Prima |

6

|

|

|

|

|

| PT Koba Tin

PT Mitra Stania Prima

PT Panca Mega Persada

PT Pelat Timah Nusantara

PT Prima Timah Utama

PT Rajwa International

PT Refined Banka Tin

PT Sariwiguna Binasentosa

PT Stanindo Inti Perkasa

PT Sumber Jaya Indah

PT Supra Sukses Trinusa

PT Timah Nusantara

PT Tinindo Inter Nusa

PT Tirus Putra Mandiri

PT Tommy Utama

PT Wahana Perkit Jaya

PT Yinchendo Mining Industry

PX Précinox SA

Rand Refinery (Pty) Ltd

Republic Metals Corporation

RFH

Royal Canadian Mint

Sabin Metal Corp.

Samduck Precious Metals

Samwon Metals

Sanher Tungsten Vietnam

Co., Ltd.

Schone Edelmetaal

SEMPSA Joyeria Plateria SA

Shandong Zhaojin Gold &

Silver Refinery Co., Ltd

Shanghai Jiangxi Metals Co.

Sichuan Metals & Materials

Imp & Exp Co

Solar Applied Materials

Technology Corp.

Solikamsk Metal Works

Sumitomo Metal Mining Co.,

Ltd.

Telex

Tejing Tungsten Co. Ltd.

Thaisarco

The Great Wall Gold and

Silver Refinery of China

The Refinery of Shandong

Gold Mining Co., Ltd

Tokuriki Honten Co., Ltd

Ulba

Umicore Brasil Ltda

Umicore SA Business Unit

Precious Metals Refining

Valcambi SA

Western Australian Mint

trading as The Perth Mint |

|

Wolfram Bergbau und Hütten AG

Wolfram Company CJSC

Xiamen Tungsten Co., Ltd.

Xinhai Rendan Shaoguan

Tungsten Co., Ltd.

Yamamoto Precious Metal

Yichun Jin Yang Rare Metal

Yokohama Metal Co., Ltd.

Yunnan Chengfeng Non-

Ferrous Metals Co., LTD

Yunnan Tin Company

Limited

Zhaojin Group and Gold

Mineral China Co., Ltd.

Zijin Mining Group Co. Ltd |

|

|

7

As the Company’s engagement with the supply chain for its products evolves and matures, this list may change

to reflect improvements in the quality of information provided to the Company.

Based solely on information that was provided by the

Covered Suppliers (as described above), some of which was on an entity level without specification as to application with respect to the specific Covered Minerals the Company purchased, and without independent verification, the Company believes that

the countries of origin of the Covered Minerals for the above listed facilities include:

|

|

|

|

|

| Australia |

|

Indonesia |

|

Russian Federation |

| Austria |

|

Italy |

|

Saudi Arabia |

| Belgium |

|

Japan |

|

South Africa |

| Bolivia |

|

Kazakhstan |

|

Spain |

| Brazil |

|

Republic of Korea |

|

Sweden |

| Canada |

|

Republic of Kyrgyzstan |

|

Switzerland |

| Chile |

|

Malaysia |

|

Taiwan |

| China |

|

Mexico |

|

Thailand |

| Estonia |

|

Netherlands |

|

Turkey |

| Germany |

|

Peru |

|

United States |

| Hong Kong |

|

Philippines |

|

Uzbekistan |

| India |

|

Poland |

|

Vietnam |

As the Company’s engagement with the supply chain for its products evolves and matures, this list may change to reflect

improvements in the quality of information provided to the Company.

Forward-Looking Statement Disclaimer

Statements made in this Report that are not of historical fact are forward-looking statements and are subject to the safe harbor provisions

of the Private Securities Litigation Reform Act of 1995. Such forward-looking statements relate to, but are not limited to, those regarding the Company’s expected future supplier diligence and engagement efforts and development of related due

diligence processes. Some factors that may affect these forward-looking statements include: regulatory changes and judicial developments relating to conflict minerals disclosure; changes in our supply chain, components and parts, or products; and

industry developments relating to supply chain diligence, disclosure and other practices. These forward-looking statements are based on current expectations and are subject to uncertainties and changes in condition, significance, value and effect as

well as other risks, including those detailed in documents filed by us with the Securities and Exchange Commission. These uncertainties and changes could cause actual results to vary from expectations. The Company undertakes no obligation to update

the information or statements made in this Report.

8

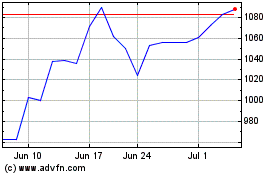

Lam Research (NASDAQ:LRCX)

Historical Stock Chart

From Mar 2024 to Apr 2024

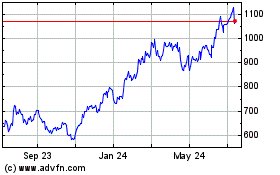

Lam Research (NASDAQ:LRCX)

Historical Stock Chart

From Apr 2023 to Apr 2024