UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

FIRST SOLAR, INC.

(Exact name of registrant as specified in its charter)

|

| | | | |

Delaware (State or other jurisdiction of incorporation) | | 001-33156 (Commission File Number) | | 20-4623678 (I.R.S. Employer Identification No.) |

350 West Washington Street

Suite 600

Tempe, Arizona 85281

(Address of Principal Executive Offices) (Zip Code)

Registrant’s telephone number, including area code: (602) 414-9300

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

|

| |

þ | Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2014. |

TABLE OF CONTENTS

|

|

Section 1 - Conflict Minerals Disclosure |

Item 1.01 Conflict Minerals Disclosure and Report |

Conflict Minerals Disclosure |

A copy of our Conflict Minerals Report is attached as Exhibit 1.02 and is available at http://investor.firstsolar.com/sec.cfm.

Our conflict minerals policy is available at www.firstsolar.com/en/about-us/corporate-responsibility/social-impact and is not incorporated herein by reference. |

|

Item 1.02 Exhibit |

The Company has filed, as an exhibit to this Form SD, the Conflict Minerals Report required by Item 1.01.

|

|

Section 2 - Exhibits |

Item 2.01 - Exhibits |

Exhibit 1.01 - Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form SD. |

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the Registrant has duly caused this Report to be signed on its behalf by the undersigned hereunto duly authorized.

|

| | | | |

| | FIRST SOLAR, INC. |

| | (Registrant) |

| | | | |

Date: | May 22, 2015 | By: | | /s/ PAUL KALETA |

| | Name: | | Paul Kaleta |

| | Title: | | Executive Vice President and General Counsel |

Exhibit 1.01

Conflict Minerals Report of First Solar, Inc.

For the reporting period from January 1 to December 31, 2014

Introduction

First Solar, Inc., together with its wholly-owned subsidiaries (“First Solar” or the “Company,” “we,” “our” or “us”), has prepared this Conflict Minerals Report pursuant to Rule 13p-1 under the Securities Exchange Act of 1934 and the requirements of Form SD (collectively, the “Rules”).

We are a global provider of solar energy solutions, focused on providing power solutions across key market segments. We design, manufacture and sell photovoltaic (“PV”) solar modules with an advanced thin-film semiconductor technology and we develop, design, construct and sell PV solar power solutions that use the solar modules we manufacture. We also manufacture crystalline silicon solar modules with proprietary high-power density, mono-crystalline technology, and we provide single-axis mounting systems with proprietary tracking capabilities. Additionally, we provide operations and maintenance (“O&M”) services to plant owners that use solar modules manufactured by us or by other third-party manufacturers. We have substantial, ongoing research and development efforts focused on module and systems level innovations. We are the world’s largest thin-film PV solar module manufacturer and one of the world’s largest PV solar module manufacturers. Our mission is to create enduring value by enabling a world powered by clean, affordable solar energy.

We operate our business in two segments:

| |

1. | Components Segment - Our components segment involves the design, manufacture and sale of solar modules which convert sunlight into electricity. We primarily manufacture cadmium telluride (“CdTe”) thin-film solar modules (“thin-film solar modules”) and, as a result of our acquisition of TetraSun, Inc. (“TetraSun”) in 2013, expect to commence sales of high-efficiency crystalline silicon solar modules in the near future. Third-party customers of our components segment include project developers, systems integrators, and owners and operators of PV solar power systems. |

| |

2. | Systems Segment - Our fully integrated systems segment provides complete turn-key PV solar power systems, or solar solutions that draw upon our capabilities, which includes (i) project development, (ii) engineering, procurement, and construction (“EPC”) services, (iii) O&M services and (iv) project finance expertise. We may provide our full EPC services or any combination of individual products and services within our EPC capabilities depending upon the customer and market opportunity. All of our systems segment products and services are for PV solar power systems which primarily use our solar modules, and such products and services are sold directly to investor owned utilities, independent power developers and producers, commercial and industrial companies, and other system owners. Additionally within our systems segment, we may hold and operate certain of our PV solar power systems based on strategic opportunities. |

Minerals including tantalum, tin, tungsten and gold (“3TG”) are classified as “conflict minerals” and are necessary to the functionality or production of certain products that we manufacture or contract to manufacture. As such, we are subject to the Rules with respect to those necessary conflict minerals. The Rules require us to conduct in good faith a reasonable country of origin inquiry (“RCOI”) into those necessary conflict minerals to determine whether they originated in the Democratic Republic of Congo (“DRC”) or an adjoining country (together, the “covered countries”) or are from recycled or scrap sources. If, as a result of our RCOI procedures, we know that any of our necessary conflict minerals originated in a covered country and are not from recycled or scrap materials, or if we have reason to believe that our necessary conflict minerals may have originated in a covered country and have reason to believe that they may not be from recycled or scrap sources, then we are required to exercise due diligence to determine the source and chain of custody of such conflict minerals to conclude if they are DRC conflict free or not.

First Solar Conflict Minerals Policy

To the extent we source minerals from the covered countries, we are dedicated to protecting and respecting human rights by responsibly sourcing such minerals. We have a long-standing commitment to conducting our business in compliance with applicable laws and regulations. First Solar condemns human rights abuses associated with the extraction, transport or trade of minerals. Similarly, First Solar has a no tolerance policy with respect to corruption, money-laundering and bribery. We require all direct suppliers to agree to follow the same principles.

At the same time, First Solar supports sourcing from the covered countries when performed in accordance with accepted international standards, specifically within the guidance from the Organisation for Economic Co-operation and Development (“OECD”).

Suppliers with minerals not found to be DRC conflict free in their sourcing will be given a reasonable amount of time to begin sourcing minerals responsibly and in a manner consistent with the principles of responsible sourcing from conflict-affected areas.

Description of Product Identification and RCOI Processes

We have concluded that, during the 2014 calendar year, we have manufactured and contracted to manufacture products containing certain conflict minerals. As such, we conducted an RCOI process to determine whether any of the conflict minerals originated, or may have originated, in the covered countries and whether such conflict minerals originated from recycled or scrap sources.

We conducted an assessment to determine which of our direct suppliers may be providing components of our products that are likely to contain conflict minerals. We employed a collaborative process to identify the applicable list of components and suppliers to focus our efforts, consulting with members of our supply chain department including commodity managers, suppliers, senior management and other individuals familiar with the manufacturing and solar plant sourcing and construction processes. We verified with such personnel that the population of components and suppliers was complete and comprehensive for our 2014 procedures. We then identified the list of suppliers that we directly procured materials from (“tier one” or “direct” suppliers) to survey. These tier one suppliers were confirmed to have supplied products or components to us that contained conflict minerals between January 1, 2014 and December 31, 2014.

The following conclusions were reached for our business segments:

| |

• | Components Segment - We consider all parts and components that go into the manufacturing and end product of our thin-film solar modules to be subject to the Rules, and they are included in our RCOI procedures. TetraSun solar module production is in the final stages of production manufacturing qualification activities. During calendar year 2014, we did not offer TetraSun solar modules to third-party customers for consideration. Accordingly, TetraSun solar modules are not considered “products” under the Rules and are not addressed in this report. |

| |

• | Systems Segment - We consider our Systems Segment to be primarily a service, and not a “product” under the Rules. We do not manufacture the majority of the parts or components used in our balance of system parts and components. For those parts that we contract, we generally do not exert design or material specification influence over the parts and components, nor are the parts and components engineered to our specifications. As such, the majority of our balance of system parts and components used within our Systems Segment are not subject to the Rules. However, there are a limited number of parts and components in our Systems Segment that we have determined to be subject to the Rules, and these are included in our RCOI procedures. In July 2014, we acquired skytron-energy (“Skytron”), a European based O&M provider that expanded our portfolio of monitored assets and greatly expanded our worldwide O&M capabilities. In accordance with the Rules, which permit the delay of reporting on the products contracted to be manufactured by an acquired company in certain cases, products contracted to be manufactured by Skytron are not addressed in this report. |

Leveraging the Conflict-Free Sourcing Initiative’s (CFSI) Conflict Minerals Reporting Template (CMRT), our RCOI consisted of surveying tier one suppliers confirmed to have supplied products or components to us that contain conflict minerals that are used to manufacture our thin-film solar modules or that we contract to manufacture for our balance of system components used in our Systems Segment. This template includes information regarding the smelters, origin of conflict minerals, supplier due diligence program and whether the material originates from recycled or scrap sources.

Our tier one suppliers performed similar RCOI procedures to identify the chain of custody from their suppliers back to the smelter and origin. We relied on the good faith efforts of our tier one suppliers to provide us with reasonable information and representations relating to the smelter and country of origin. The smelter or refiner facilities that were used to process our necessary conflict minerals are contained in Appendix A. See “Smelters and Refiner Facilities” below for more detail regarding the information contained in Appendix A.

Results

We received completed surveys from all suppliers included in the procedures outlined above and came to the following conclusions:

| |

• | Components Segment - 65% of our applicable suppliers support our Components Segment. The applicable results showed that tin is the only conflict mineral of the thin-film solar module parts. |

| |

• | Systems Segment - 35% of our applicable suppliers support our Systems Segment. The applicable results showed that tin is the primary conflict mineral of our solar power systems. Additionally, tungsten, tantalum and gold are contained in our Tracker system, which contains an electrical gateway, controller, and other parts that support functionality to follow the sun’s irradiance throughout the day. |

Based on the RCOI conducted for both segments, we have reason to believe that a portion of our necessary conflict minerals originated or may have originated in the covered countries and have reason to believe that those necessary conflict minerals may not be from recycled or scrap sources. Based on this result, we exercised due diligence to determine the source and chain of custody of such conflict minerals as described below.

Framework Used to Develop Due Diligence Measures

In accordance with the Rules, we undertook due diligence efforts to determine the country, mine or location of origin and facilities used to produce the conflict minerals used in our products. We have designed our due diligence measures to conform in all material respects with the internationally recognized due diligence framework as set forth in the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Framework”) and related supplements for 3TG.

Due Diligence Undertaken to Comply with the OECD Framework

Our due diligence process for 2014 included the following steps:

OECD Step 1: Establish a Company Management System

| |

• | We have adopted and communicated our conflict minerals policy both publicly and to relevant internal and external parties. |

| |

• | Our conflict minerals policy is available at www.firstsolar.com/en/about-us/corporate-responsibility/social-impact. Our conflict minerals policy is not incorporated herein by reference. |

| |

• | We have adopted conflict minerals compliance language in our supplier agreements and purchase order terms and conditions. |

| |

• | We have an operating cross-functional internal governance team with representatives from our supply chain, legal, sustainability and finance departments to ensure policy statements and control processes are followed. |

| |

• | We have an existing records retention process and grievance mechanism for reporting violations of policy via our company hotline. |

OECD Step 2: Identify and Assess Risks in Supply Chain

| |

• | We conducted our surveys leveraging the CMRT, which was sent to all suppliers deemed to be subject to the Rules. We used the CMRT to identify smelter or refiner facilities and country of origin of our necessary conflict minerals. |

| |

• | We relied on information provided by the CFSI to identify countries of origin for Conflict-Free Smelter Program (“CFSP”) compliant smelter or refiner processing facilities. |

| |

• | We reviewed the responses from the CMRT questionnaires with our supply chain department cross-checking the list of CFSP-compliant processing facilities. |

OECD Step 3: Design and Implement a Strategy to Respond to Risk

| |

• | We reported information on the source and chain of custody of our necessary conflict minerals to our conflict minerals steering committee, executive management and the Audit Committee of our Board of Directors on a periodic basis. |

| |

• | As part of our internal conflict minerals policy, we have a conflict minerals risk mitigation plan that defines supplier-risk management strategies, including a) continued procurement, b) assistance in identifying alternate sources of supply and c) disengagement, the severity of which is at the discretion of our conflict minerals steering committee and executive management. |

OECD Step 4: Independent Third-Party Audit of Smelter/Refiner’s Due Diligence Practices

| |

• | As we do not source directly from smelter or refiner processing facilities, we rely on the CFSP to oversee and coordinate third-party audits of these facilities. The CFSP audit protocols and procedures were designed by the CFSI, who engage specially trained third-party auditors to independently verify that these smelters and refiners can be deemed conflict-free. |

| |

• | We rely on the publicly-available audit results of the CFSP third-party audits to validate the sourcing practices of processing facilities in our supply chain. |

OECD Step 5: Report Annually on Supply Chain Due Diligence

| |

• | We will file a Form SD and Conflict Minerals Report with the SEC on an annual basis, as necessary. Our Form SD and Conflict Minerals Report are also available on our website at http://investor.firstsolar.com/sec.cfm. |

Smelter and Refiner Facilities

For our Components and Systems Segments, Malaysia Smelting Corp., Malaysia (“MSC”) is the only known smelter identified through our due diligence process that was found to be sourcing from the covered countries.

MSC, which is certified under the CFSP, reported that it sources 15-20% of the tin it produces from predominantly artisanal miners in Central Africa and that the majority of its smelter intake from Central Africa is currently from Rwanda and the southern Katanga Province of the DRC, which is not within the recognized conflict areas of eastern DRC. Further, MSC reported that all tin concentrates it purchases from Rwanda and Katanga is obtained through the International Tin Supply Chain Initiative (“iTSCi”) program, which is aligned with the OECD Framework. This information was obtained from publicly available information found on MSC’s website (http://www.msmelt.com/abt_policy.htm), which website is not incorporated by reference herein.

For our Systems Segment, we do not have a full population of all smelters used in the Tracker component supply chain. Through performance of our RCOI and diligence procedures, the supplier of the Tracker components is currently mapping and identifying the smelters and chain of custody of materials in its supply chain.

Though we request that our tier one suppliers provide responses at the product-level, some of those suppliers provided responses at the company-level. As such, our list of processing facilities disclosed in Appendix A may contain more facilities than those that actually process the conflict minerals contained in our products.

Due Diligence Efforts to Identify Country, Location and Mine of Origin of Conflict Minerals in Products

After obtaining Conflict Minerals Supplier Forms and related documentation through our RCOI and due diligence processes as described above, we compared the smelters/refiners used by relevant suppliers against an independently verified list of smelters/refiners leveraging the audit results from the CFSP (www.conflictfreesmelter.org) (which website is not incorporated by reference herein) as well as responses in the CMRT to gather the country, location and mine of origin information. In addition, for smelters not certified under the CFSP, we obtained written representations regarding the chain of custody and origin of such minerals smelted in order to identify the mine or location of origin with the greatest amount of specificity possible.

Continuous Improvement Efforts to Mitigate Risk

We intend to advance the effectiveness of our due diligence efforts, further enhance our compliance processes and mitigate any risk that the necessary conflict materials used in our products may benefit armed groups by taking the following steps:

| |

1. | Engage further with direct suppliers and processing facilities to: |

| |

• | Improve the quality of processing facility data provided by our direct suppliers via the CMRT, including country of origin and mine or location of origin. |

| |

• | Encourage non-CFSP validated processing facilities to become validated either through the CFSP or a CFSP-recognized third-party audit program. |

| |

2. | Continue to require conflict minerals compliance language in our supplier agreements and refine our internal operating procedures to continue to move towards a “DRC conflict free” supply chain across all business segments. |

| |

3. | Continue to monitor and track the RCOI and due diligence progress of our non-CFS suppliers, including the usage of smelters and refiners which have been certified by the CFS. |

| |

4. | Require periodic supplier re-certifications to confirm that their previously reported sourcing information has not changed. |

Appendix A

Table of Our Conflict Minerals Processing Facilities

|

| | | | | | | | | | |

| | | | | | | | Covered Products |

Conflict Mineral | | Smelter Name** | | Smelter Location | | CFSP Status | | Components Segment | | Systems Segment |

Tin | | EM Vinto | | Bolivia | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | Malaysia Smelting Corporation (MSC) | | Malaysia | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | Metallo Chimique | | Belgium and Spain | | CFSP Compliant Tim Smelter | | X | | X |

Tin | | Mineração Taboca S.A. | | Brazil | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | Minsur | | Perù | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | OMSA | | Bolivia | | CFSP Compliant Tin Smelter | | | | X |

Tin | | PT Bangka Putra Karya | | Indonesia | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | PT Belitung Industri Sejahtera | | Indonesia | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | PT Timah (Persero), Tbk | | Indonesia | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | PT Refined Bangka Tin | | Indonesia | | CFSP Compliant Tin Smelter | | X | | |

Tin | | Alpha | | United States | | CFSP Compliant Tin Smelter | | X | | |

Tin | | Thaisarco | | Thailand | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | White Solder Metalurgia e Mineração Ltda. | | Brazil | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | Yunnan Tin Company, Ltd. | | China | | CFSP Compliant Tin Smelter | | X | | X |

Tin | | Cooper Santa | | Brazil | | Active Smelters List* | | X | | |

Tin | | Fenix Metals | | Poland | | Active Smelters List* | | X | | |

Tin | | Yunnan Chengfeng Non-ferrous Metals Co., Ltd. | | China | | Active Smelters List* | | X | | X |

Tin | | Gejiu Zi-Li | | China | | Not certified | | X | | X |

Tin | | Novosibirsk Integrated Tin Works | | Russian Federation | | Not certified | | X | | |

Tin | | CNMC (Guangxi) PGMA Co. Ltd. | | China | | Not certified | | X | | |

Tin | | PT Koba Tin | | Indonesia | | Not certified | | | | X |

Tungsten | | Kennametal Huntsville | | United States | | Active Smelters List* | | | | X |

*Smelters on the Active list have committed to undergo a CFSP audit. Smelters are identified as Active in the CFSP once they submit a signed Agreement for the Exchange of Confidential Information (AECI) and Auditee Agreement contracts. This is the first step of the audit process. Smelters on the Active list are at various stages of the audit cycle, anywhere from completion of the necessary documents to scheduling the audit date to enacting corrective actions in the post-audit phase.

**Though we request that our tier one suppliers provide responses at the product-level, some of those suppliers provided responses at the company-level. As such, our list of processing facilities disclosed in this appendix may contain more facilities than those that actually process the conflict minerals contained in our products.

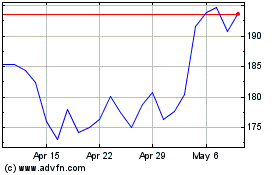

First Solar (NASDAQ:FSLR)

Historical Stock Chart

From Mar 2024 to Apr 2024

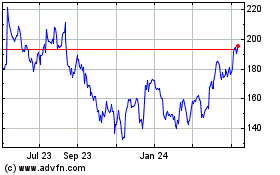

First Solar (NASDAQ:FSLR)

Historical Stock Chart

From Apr 2023 to Apr 2024